A kind of natural antibacterial and mildew-resistant PLA refrigerator fresh-keeping liner and its processing technology

A natural, liner technology, applied in other home appliances, lighting and heating equipment, household refrigeration equipment, etc., can solve the problems that affect people's health, the liner is not degradable, easy to mold bacteria, etc., to achieve good antibacterial and mildew resistance Effect, increase interface adhesion, effect of practical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

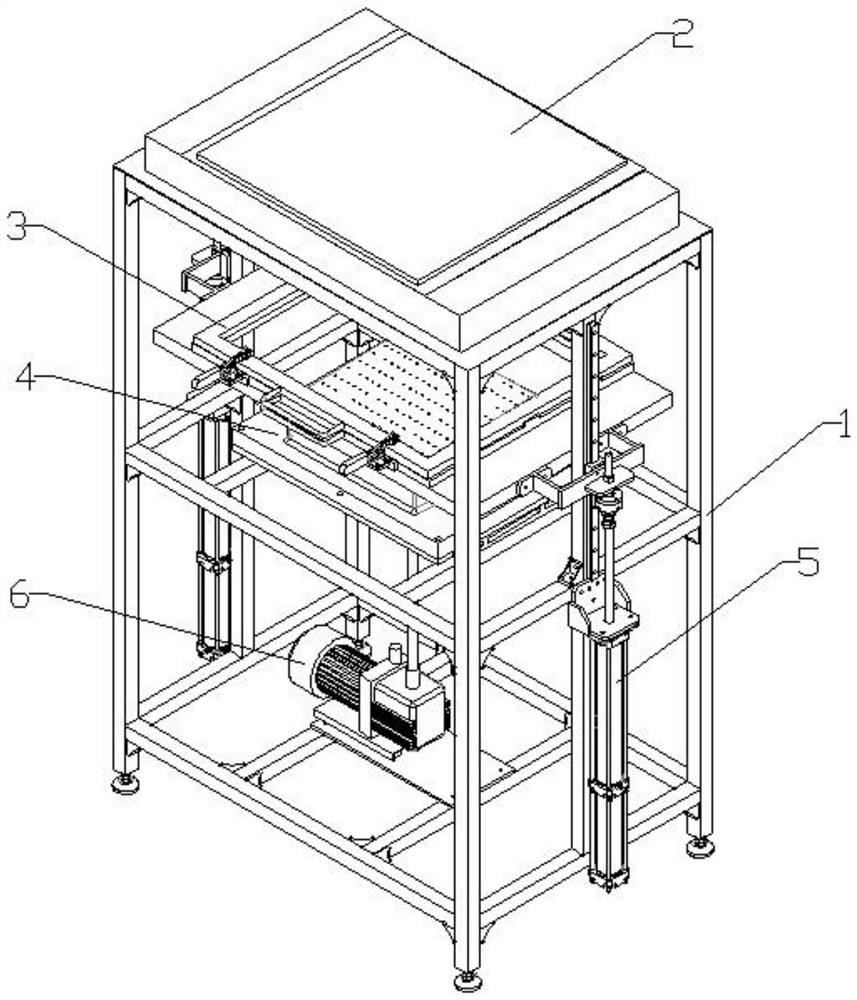

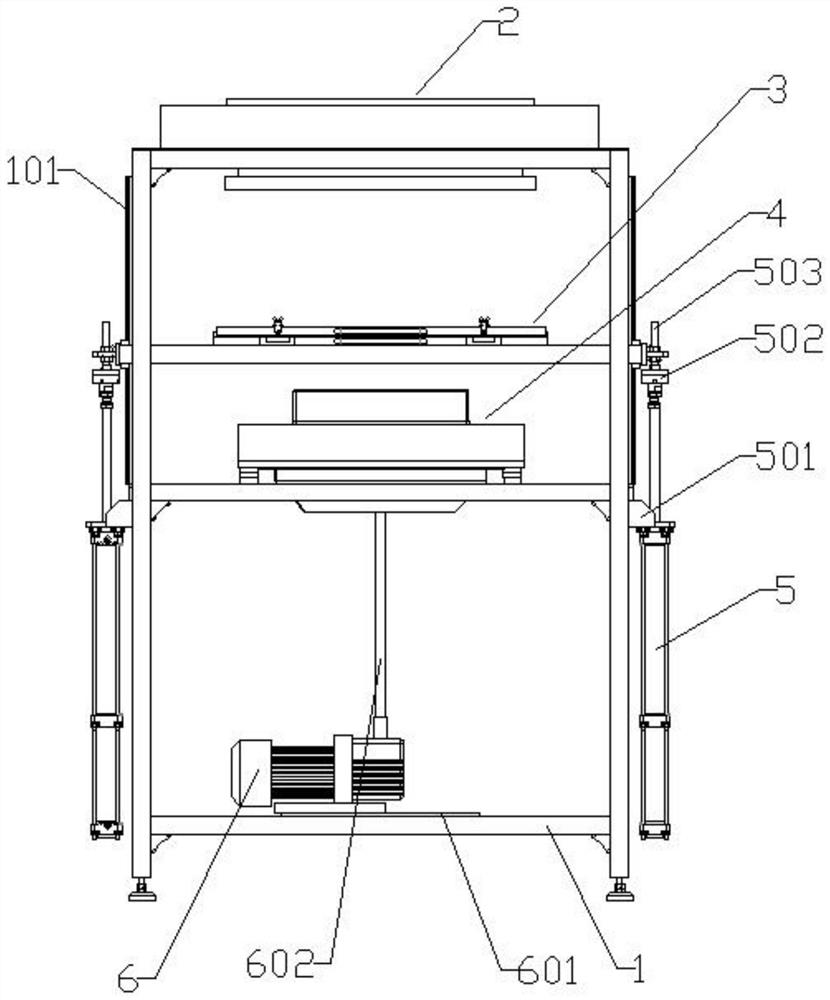

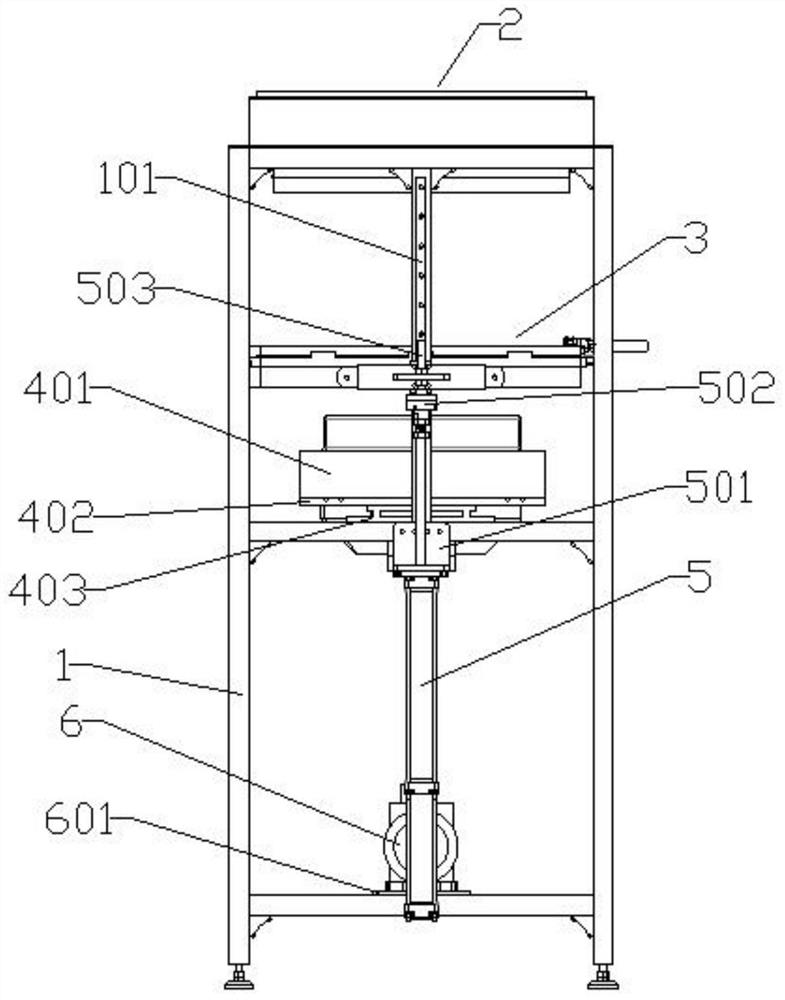

Image

Examples

Embodiment 1

[0045] A natural antibacterial and anti-mildew type PLA refrigerator fresh-keeping liner, comprising the following raw materials in parts by weight: 40 parts of polylactic acid, 20 parts of polyethylene glycol, 4 parts of glycerin, 6 parts of active bacteriostatic agent, and 5 parts of natural anti-mold agent , 2 parts of active antioxidants;

[0046] This kind of natural antibacterial and anti-mold PLA refrigerator fresh-keeping liner is processed by the following steps:

[0047] Step S1: Put the polylactic acid in a vacuum drying oven, vacuum-dry it for 4 hours at a vacuum degree of 0.1Mpa and a temperature of 45°C, and then add the dried polylactic acid and polyethylene glycol into the mixer , at a temperature of 120°C, mix the materials for 10 minutes, add them to the twin-screw extruder after mixing, set the feed rate to 100g / min, and add glycerin to the twin-screw extruder from the side feed port at the same time, Extrude and granulate at a temperature of 190°C to prepa...

Embodiment 2

[0057] A natural antibacterial and anti-mildew type PLA refrigerator fresh-keeping liner, comprising the following raw materials in parts by weight: 50 parts of polylactic acid, 25 parts of polyethylene glycol, 5 parts of glycerin, 8 parts of active bacteriostatic agent, and 7 parts of natural anti-mold agent , 4 parts of active antioxidants;

[0058] This kind of natural antibacterial and anti-mold PLA refrigerator fresh-keeping liner is processed by the following steps:

[0059] Step S1: Place the polylactic acid in a vacuum drying oven, vacuum-dry it for 5 hours at a vacuum degree of 0.1Mpa and a temperature of 50°C, and then add the dried polylactic acid and polyethylene glycol into the mixer , at a temperature of 140°C, mix the materials for 15 minutes, add them to the twin-screw extruder after mixing, set the feed rate to 100g / min, and add glycerin to the twin-screw extruder from the side feeding port at the same time, Extrude and granulate at a temperature of 190°C to ...

Embodiment 3

[0069]A natural antibacterial and anti-mildew type PLA refrigerator fresh-keeping liner, comprising the following raw materials in parts by weight: 60 parts of polylactic acid, 30 parts of polyethylene glycol, 6 parts of glycerin, 10 parts of active bacteriostatic agent, and 8 parts of natural anti-mold agent , 6 parts of active antioxidants;

[0070] This kind of natural antibacterial and anti-mold PLA refrigerator fresh-keeping liner is processed by the following steps:

[0071] Step S1: Place the polylactic acid in a vacuum drying oven, vacuum-dry it for 6 hours at a vacuum degree of 0.1Mpa and a temperature of 55°C, and then add the dried polylactic acid and polyethylene glycol into the mixer , at a temperature of 160°C, mix the materials for 20 minutes, add them to the twin-screw extruder after mixing, set the feed rate to 100g / min, and add glycerin to the twin-screw extruder from the side feed port at the same time, Extrude and granulate at a temperature of 190°C to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com