Waste plastic bottle recycling treatment method

A technology of waste plastics and processing methods, which is applied in the direction of plastic recycling, recycling technology, mechanical material recycling, etc., can solve the problems of staff injuries, waste plastic bottles polluting the environment, and slow recycling speed of waste plastic bottles, etc., to achieve convenient clamping The effect of fixing and improving the efficiency of cutting and crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

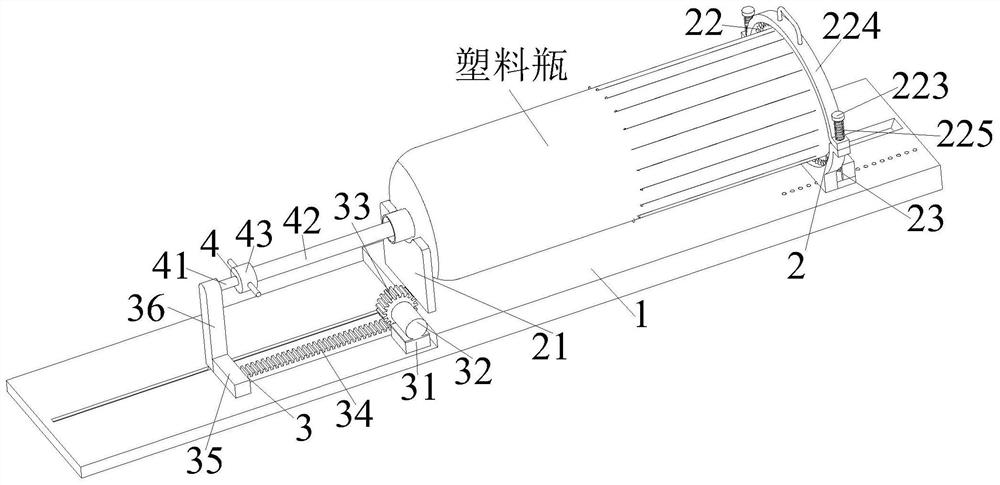

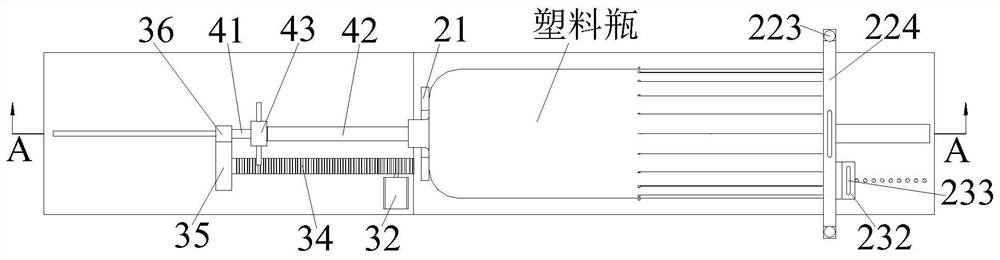

[0040] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

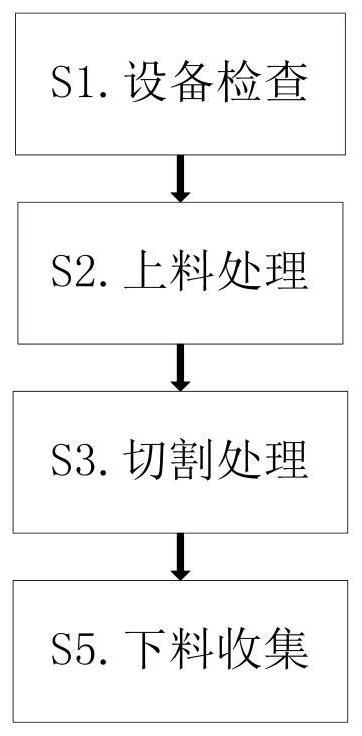

[0041] A recycling treatment method for waste plastic bottles, the specific recycling method is as follows:

[0042] S1. Equipment inspection: Recycle plastic bottles before using waste plastic bottle recycling equipment to recycle them;

[0043] S2. Feeding treatment: After the equipment inspection is completed, manually place the plastic bottle to be broken on the bottom plate 1, so that the clamping device 2 can clamp and fix the plastic bottle;

[0044] S3. Cutting treatment: After the feeding is completed, the cutting device 4 is manually placed in the plastic bottle, so that the cutting device 4 can cut the plastic bottle;

[0045] S4. Cutting material collection: after the cutting is completed, the cut plastic bottles are manually removed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com