Positioning fixture for clamping precision castings

A technology for positioning fixtures and precision castings, applied in the field of fixture tooling, which can solve the problems of accumulation of clamping errors, lateral or vertical displacement of parts, out of tolerance of parts, etc., and achieves the effect of reducing processing cycles, simple device structure, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

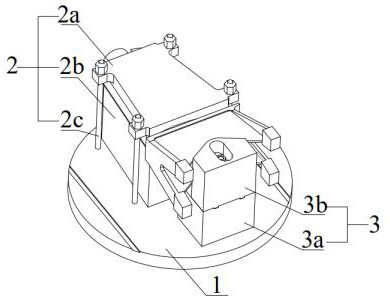

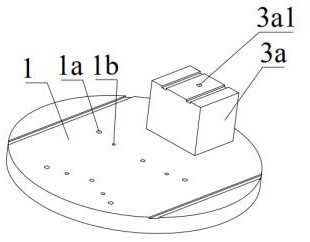

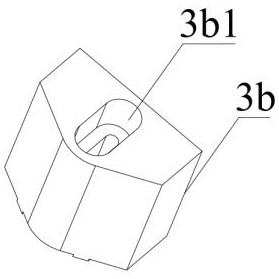

[0034] as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4As shown, after the precision casting is clamped by the positioning fixture, it is installed on the five-axis machine tool through the base 1. The base 1 of the positioning fixture is provided with a vertical pressing mechanism 2 and a horizontal pressing mechanism 3. Through the vertical pressing mechanism 2 Act on the upper and lower end surfaces of the precision casting, and press the precision casting vertically, so as to avoid the vertical movement of the precision casting when the holes at both ends of the precision casting are processed, through the horizontal compression mechanism 3 Press against the end of the precision casting along the lateral direction, thereby limiting the lateral movement of the precision casting during processing, thereby avoiding the lateral movement of the precision casting due to the lateral force when processing the outer end surface of the bayonet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com