A corn thresher based on counter-rotating double rollers and capable of improving the cleaning rate

A technology of reverse rotation and threshing machine, applied in threshing equipment, agricultural machinery and tools, agriculture, etc., can solve the problems of unconsidered, leakage, and single threshing means, so as to increase the amount of feed and enhance work efficiency , Improve the effect of threshing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

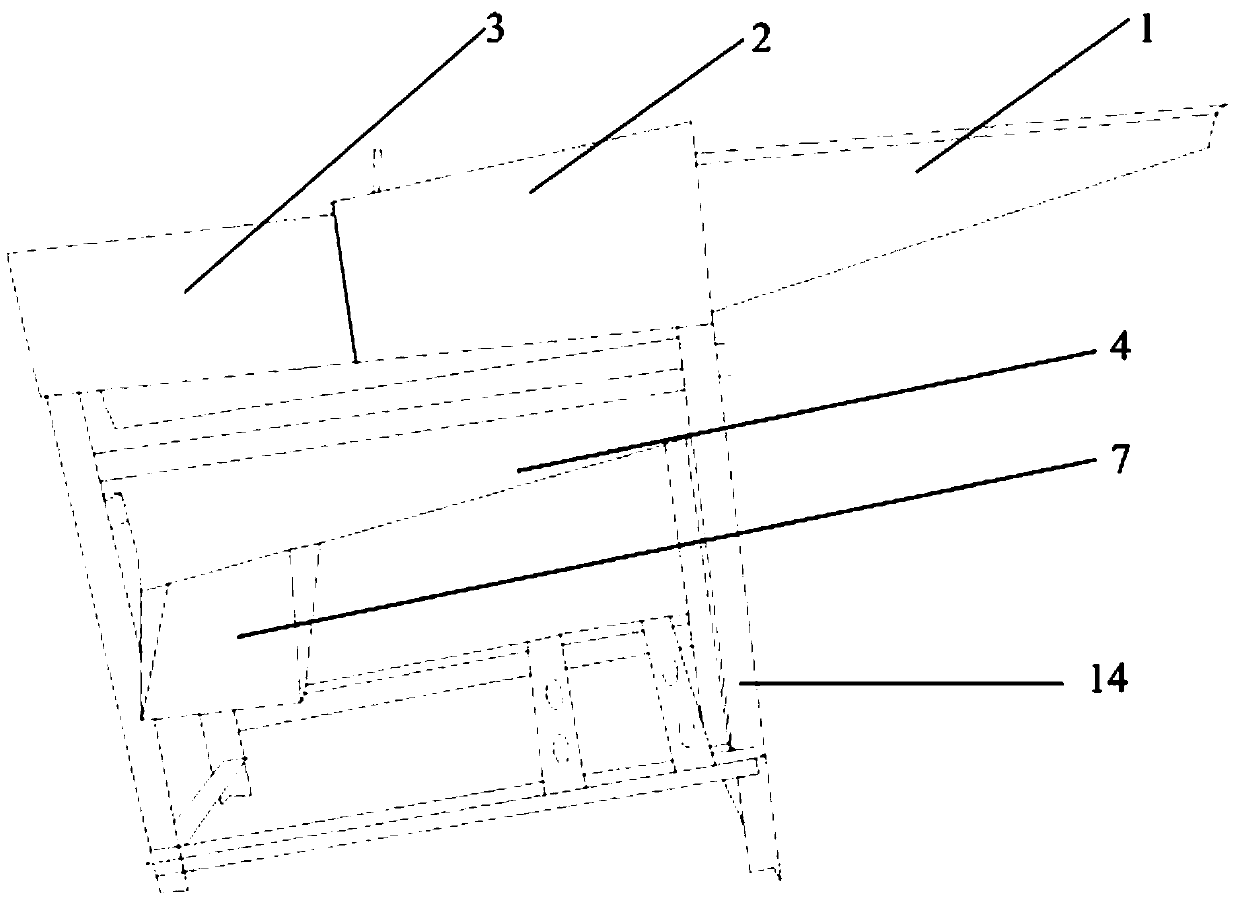

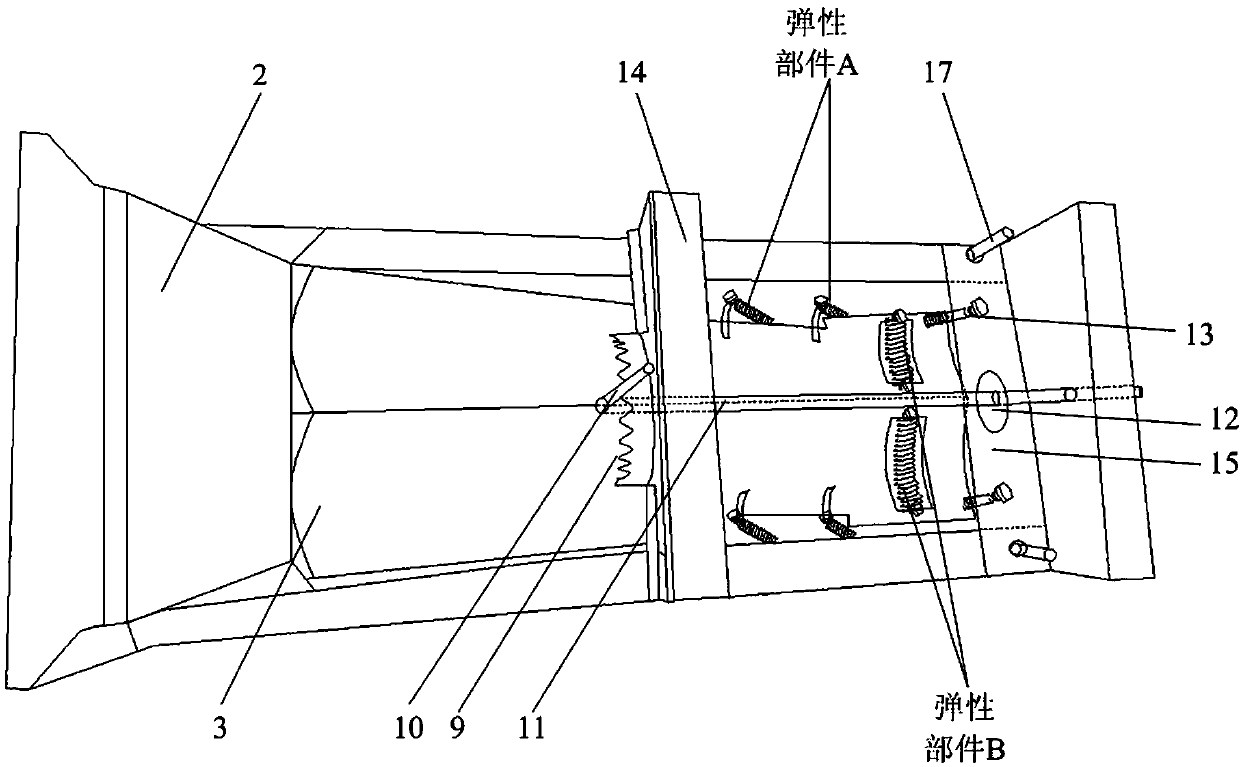

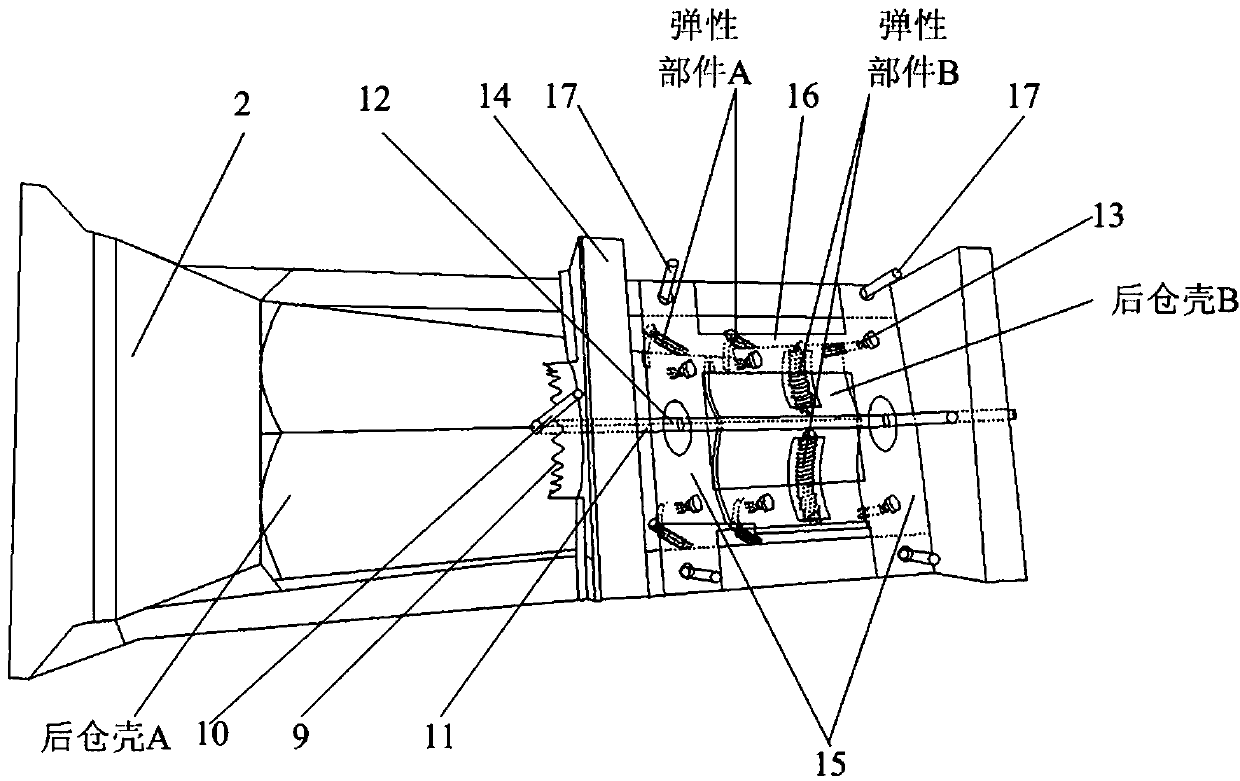

[0032] Such as Figure 1-Figure 6 Shown:

[0033] A corn thresher based on counter-rotating double rollers, including a feed hopper 1, a front silo shell 2, a rear silo shell 3, a left side plate 5, a right side plate 6, a bottom plate 4 and a discharge port. 2. Two counter-rotating threshing rollers 8 are installed at intervals in the threshing space formed between the rear shell 3, the left side plate 5, the right side plate 6 and the bottom plate 4. The rear shell 3 is composed of two Composed of arc-shaped pressing plates, when the threshing rollers 8 all rotate to the outside of the corn thresher, a number of elastic parts A are fixed at intervals on the outer edge of the rear shell; when the threshing rollers 8 all rotate to the inside of the corn thresher, the A number of elastic parts A are fixed at intervals on the inner edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com