Y-axis mechanism of turning and milling composite machine tool

A compound machine tool and Y-axis technology, which is applied in the direction of metal processing machinery parts, large fixed members, metal processing, etc., can solve the problems of slow fast moving speed, small Y-axis stroke, poor cutting rigidity, etc., so as to improve the force, reduce the Small overturning force, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

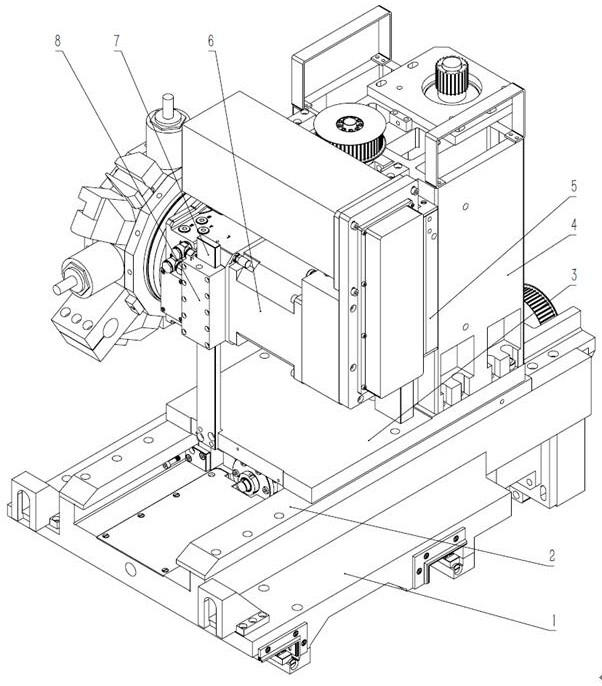

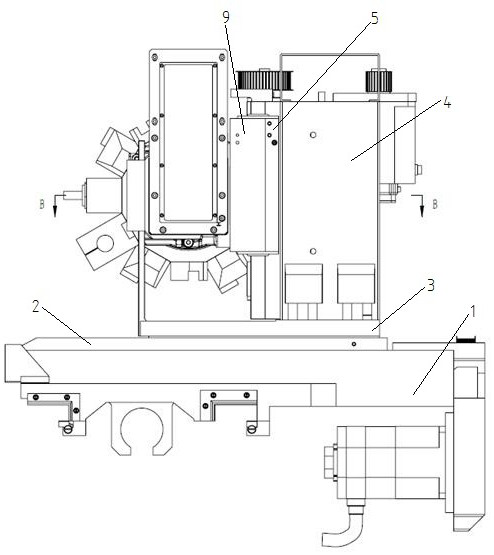

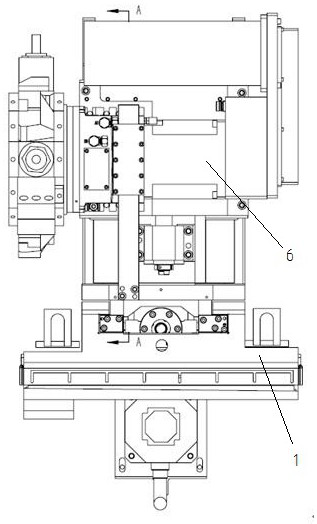

[0024] The present invention relates to a Y-axis mechanism of a turn-milling compound machine tool, comprising a Y-axis column 4 and a tool holder 6, the Y-axis column 4 is vertically fixed on an X-axis slide plate 3, and the X-axis slide plate 3 is slidably mounted on On the carriage 1, an X-axis handle plate 9 is provided. The left side of the Y-axis column 4 is provided with a Y-axis slide plate 9 that can slide in the Y direction Driven, the tool rest 6 is installed on the Y-axis slide plate 9.

[0025] The X-axis slide plate 3 is also provided with a vertical auxiliary guide rail 7, the left side of the tool holder 6 is slidably connected to the auxiliary guide rail 7 and a locking cylinder 8 is arranged between them. In the orthogonal Y-axis turning-milling compound machine tool, the Y-axis hydraulic control plate 5, auxiliary guide rail 7 and its locking cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com