Method for producing narrow-thickness-tolerance X12Ni5 steel through single-rack steckel mill

A technology of thickness tolerance and steckel rolling mill, which is applied in the field of rolling narrow thickness tolerance steel plates and producing narrow thickness tolerance X12Ni5, can solve the problems of thickness precision control, etc., achieve stable control, improve enterprise economic benefits and market competitiveness, and improve Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the following examples.

[0026] This embodiment further explains the X12Ni5 steel with a thickness of 6 mm and a narrow thickness tolerance requirement. The mass percentage composition of X12Ni5 billet is: C<0.1%, Si0.1%~0.5%, Mn0.2%~1%, P<0.02%, S<0.02%, Ni4.5%~5.5%, Cr<0.2 %, Mo<0.15%, Cu<0.5%, V<0.1%, and the rest are Fe and unavoidable impurities.

[0027] (1) See Table 1 for specific material design;

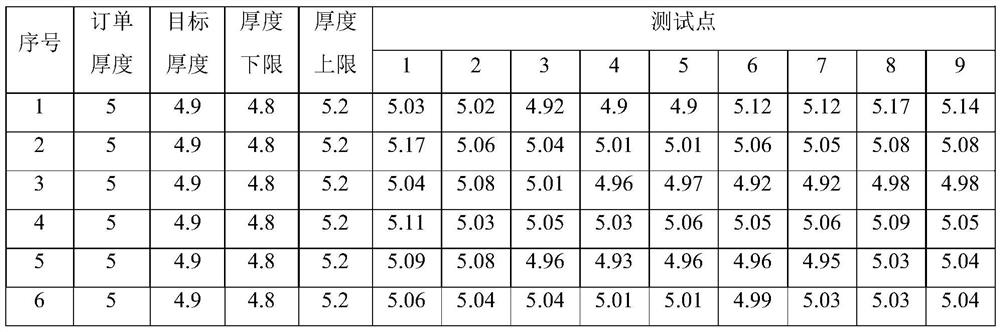

[0028] Table 1 Material design data

[0029] Example number rolled steel Blank size Rolling length 1 X12Ni5 150×2600×8402mm 210m 2 X12Ni5 150×2850×8243mm 206m

[0030] (2) Planning arrangement: two rolled pieces will be produced after 550 tons in the middle and early stage of the work roll period, and the production will be controlled within 1000 tons in the middle and earl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com