Narrow Thickness Tolerance Control Method for Thin Gauge Steel Plate in Single Stand Steckel Mill

A technology of thickness tolerance and steckel rolling mill, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of narrow supply width, large internal stress, and restrictions on the development of the cruise manufacturing industry, and achieve stable control , Reduce batches of unqualified products and improve the effect of enterprise economic benefits and market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

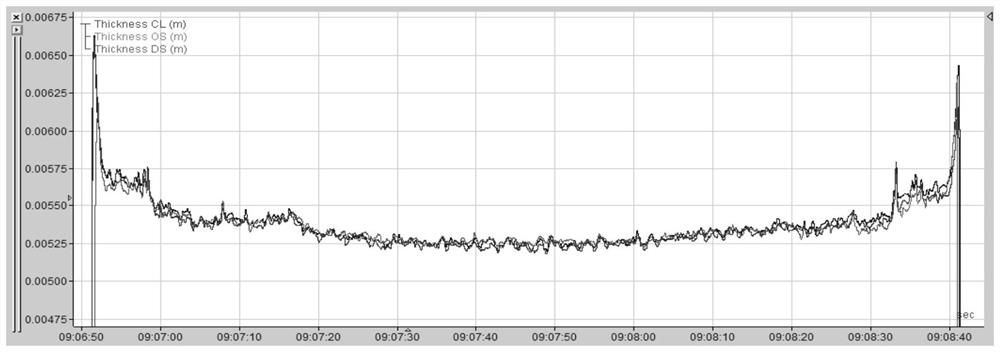

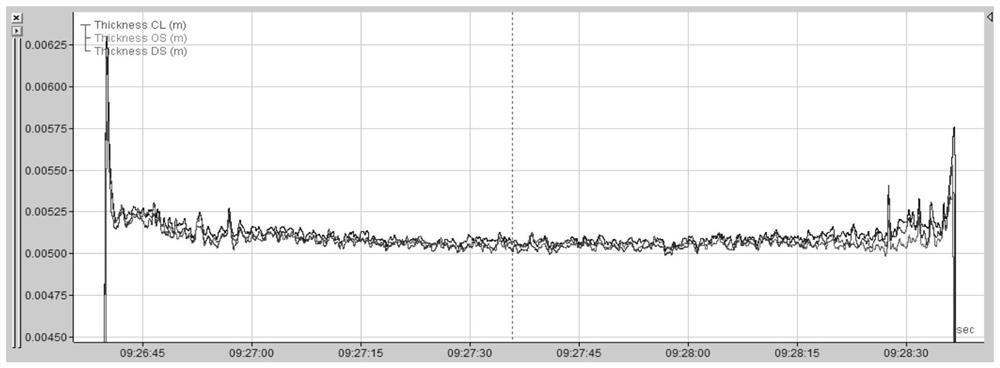

[0027] The technical scheme of the present invention will be described in further detail below.

[0028] This embodiment selects rolling order thickness 5mm BV-A36, and the whole production process is controlled as follows:

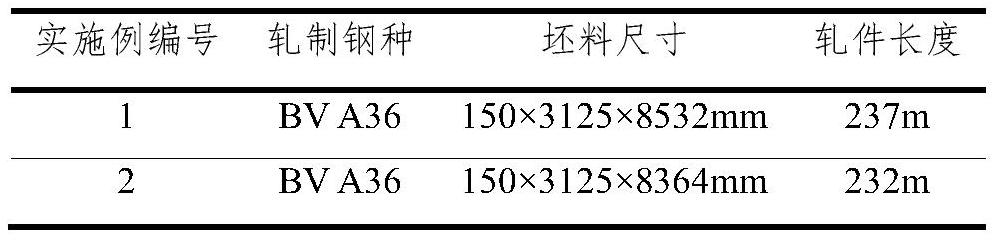

[0029] (1) See Table 1 for specific material design, 1# heating furnace double-row steel loading;

[0030] Table 1 Material design data

[0031]

[0032] (2) Planning arrangement: two rolling pieces will be produced after 512 tons in the middle and early stage of the work roll period, and the production will be controlled within 1000 tons in the middle and early stage of the work roll period. Before production, 2 pieces of 1# heating furnace with a thickness of 5mm will be ordered. BV A36 will be used as the transition blank To adjust the thickness deviation, the width of the 2# heating furnace billet produced at the same time is 3068-3098mm, and all of them are required by the heating system of 1180±20°C.

[0033] (3) See Table 2 for the specific he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com