Nickel-based methane catalyst as well as preparation method and application thereof

A nickel-based catalyst and nickel salt technology, applied in the field of electrochemistry, can solve the problems of easy sintering, poor thermal stability of nickel single atoms, deactivation, etc., achieve stable and reliable performance, avoid carbon deposition and deactivation, and improve activity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

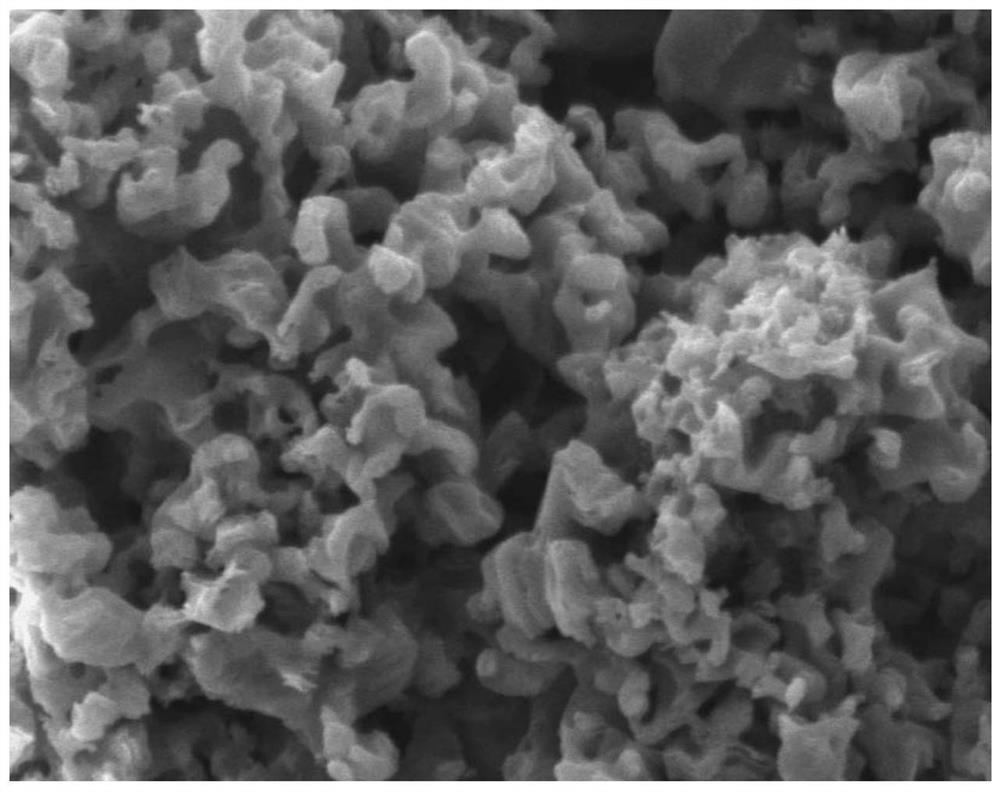

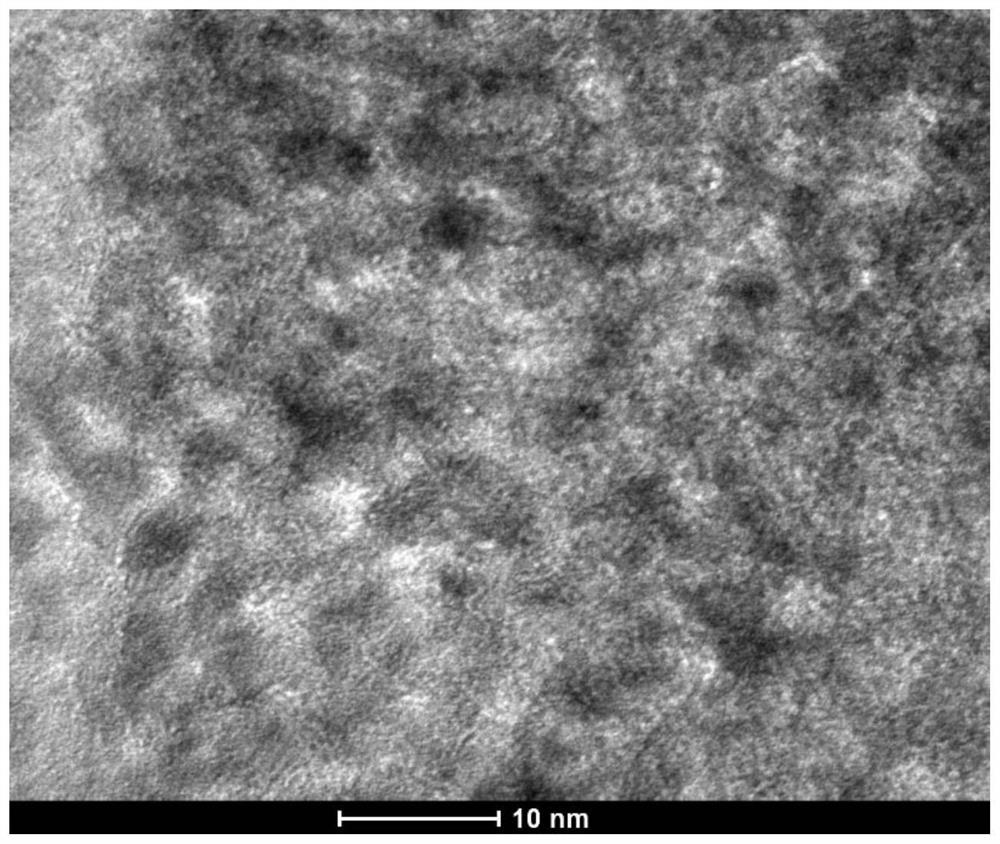

[0026] The preparation technology of described nickel sheet specifically comprises the steps:

[0027] 1. Nickel foam pretreatment: Cut the nickel foam into the required shape, soak in hydrochloric acid aqueous solution with a mass concentration of 0.5% to 5.0% for 1min to 5min, and then wash with deionized water. Then, it is ultrasonicated for 10 min to 30 min in an ammonia solution with a mass concentration of 1.0% to 15.0%, and then cleaned with deionized water. After cleaning, dry at 50° C. to 100° C. for 2 hours to obtain a nickel foam substrate.

[0028] 2. Preparation of foamed nickel-supported nickel single atom nickel sheet by hydrothermal method: put 5mL~20mL of 0.01%~1.0% nickel nitrate aqueous solution into a 100mL beaker (any nickel salt soluble in ethanol can be used for this place), then add 1-10 mL of ethanol and 0.1-2 mL of oleylamine, and stir for 10-30 minutes to obtain a nickel nitrate ethanol-oleylamine solution. Transfer the nickel nitrate ethanol-oleyl...

Embodiment

[0033] 1. Foamed nickel pretreatment: Cut the foamed nickel into a cuboid of 1cm×4cm×0.5mm, soak it in a hydrochloric acid aqueous solution with a mass concentration of 2.0% for 5 minutes, wash it with deionized water, and then soak it in a 5.0% ammonia solution with a mass concentration Ultrasonic for 30 min, then washed with deionized water, and dried for 2 h at a temperature of 80° C. to obtain a nickel foam substrate.

[0034] 2. Preparation of foamed nickel-supported nickel single-atom electrode by hydrothermal method: Put 20mL of 0.5% nickel nitrate aqueous solution into a 100mL beaker, then add 10mL of ethanol and 1mL of oleylamine mixture, and stir for 30min. Then transfer to a 50mL polytetrafluoroethylene hydrothermal reaction kettle, put the nickel foam pretreated in step 1 vertically into the reaction kettle equipped with nickel nitrate ethanol-oleylamine solution, at a temperature of 120°C Reaction 10h. Then cool down to room temperature naturally, open the hydrot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com