Method for testing cohesive force of lithium ion battery pole piece

A technology of lithium ion battery and testing method, which is applied in the field of testing the adhesion of lithium ion battery pole pieces, can solve the problems of reducing battery performance, affecting battery cycle life, affecting battery self-discharge, etc., so as to avoid batch abnormality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Taking the negative plate of 18650 lithium iron phosphate cylindrical battery as an example, the specific steps are as follows

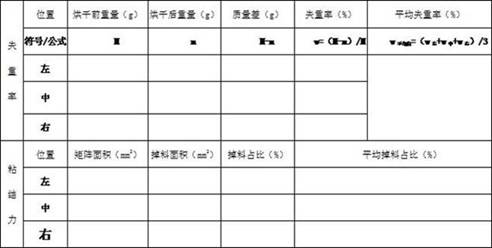

[0018] 1) Take the single-sided negative electrode piece after coating and drying. The size is about: length: 300mm, width: 200mm. The wafer area is 1000mm 2 (The diameter of the circle is 35.7mm), samples are taken from the left, middle and right respectively, and the recording quality before baking is M 左 , M 中 , M 右 ;

[0019] 2) Put it into an oven with a temperature of 90±5°C and bake for 5~8 minutes, and record the mass as m after baking 左 、m 中 、m 右 ; Through the formula: w=(M-m) / M*100%, respectively calculate the weight loss rate w of the three small discs 左 ,w 中 ,w 右 ;Finally find w 平均值 , and record it;

[0020] 3) Put the three sets of circular pole pieces punched out above flatly on the glass plate / steel plate, with the coating area facing upwards, and use a special blade drawing meter to draw across the pole piece at a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com