Setting machine monitoring and management system

A technology of monitoring management and setting machine, which is applied in the field of setting machine monitoring and management system, can solve the problems of no automatic combination of production management and process monitoring management, no monitoring system association, and incomplete production process data, so as to avoid energy consumption. Effects of wastage and product quality degradation, improvement of energy utilization, optimization of process equipment and process settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

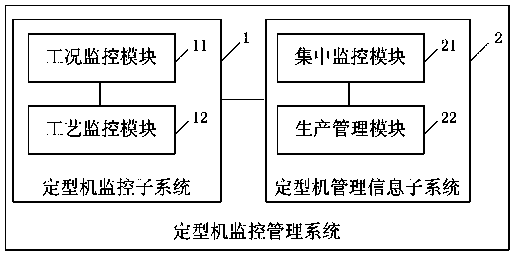

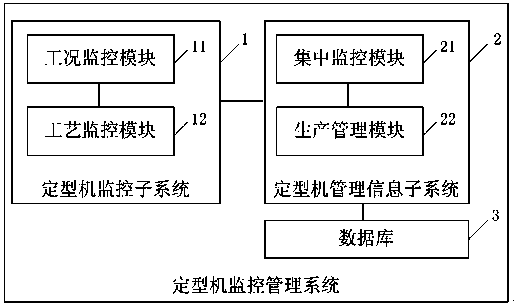

[0044] combine figure 1 , figure 2 , image 3 and Figure 4 , the present invention is a stereotype machine monitoring and management system, including a stereotype machine monitoring subsystem 1 and a stereotype machine management information subsystem 2;

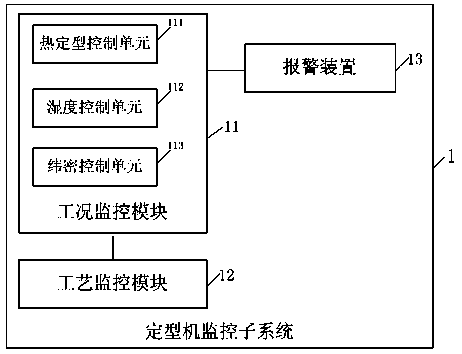

[0045] The setting machine monitoring subsystem 1 is used to monitor a setting machine, including:

[0046] The working condition monitoring module 11 is used to monitor each shaping process, and generate and store process data;

[0047] The process monitoring module 12 is used to obtain the process sheet and process settings entered by the user in the production management module, execute the process sheet, collect the process data, and monitor the process conditions in real time;

[0048] The stereo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com