Preparation method of compact Fe2O3 film based on step voltage

A step voltage, fe2o3 technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of cumbersome process and non-dense film, achieve high photoelectric conversion efficiency and realize the effect of dense arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

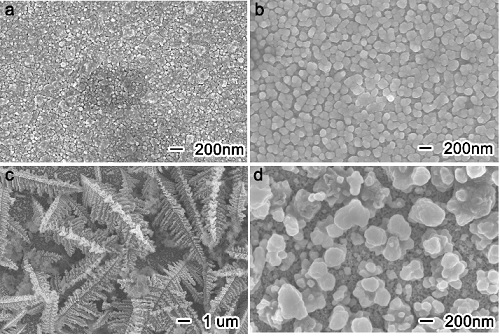

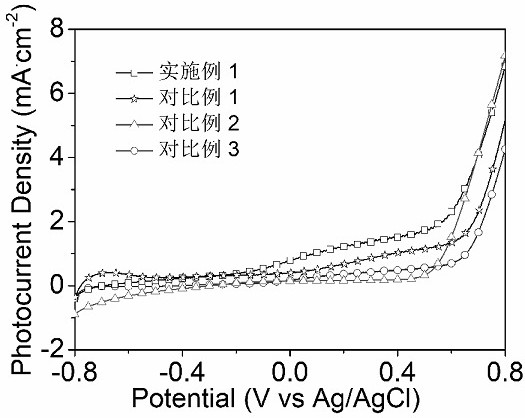

[0072] Preparation of Fe by step voltage 2 o 3 film

[0073] 1) Use acetone and deionized water to ultrasonically clean the FTO conductive glass, repeat it several times until it is cleaned, and then dry it for later use.

[0074] 2) Weigh a certain amount of boric acid, ascorbic acid, ferrous sulfate heptahydrate and PEG20000, dissolve them in deionized water, and prepare the required electrolyte. Wherein the molar concentration of boric acid is 0.2mol . L -1 ; The molar concentration of ascorbic acid is 0.0006mol . L -1 ; The molar concentration of ferrous sulfate heptahydrate is 0.2mol . L -1 ; The molar concentration of PEG20000 is 0.0012mol . L -1 .

[0075] A three-electrode electrolysis system composed of FTO conductive glass, graphite electrode, Ag / AgCl electrode and the above-mentioned electrolyte is adopted, and a step voltage deposition process is used to generate electricity on the surface of FTO conductive glass by changing the applied voltage between FT...

Embodiment 2

[0116] Preparation of Fe by step voltage 2 o 3 film

[0117] 1) Use acetone and deionized water to ultrasonically clean the FTO conductive glass, repeat it several times until it is cleaned, and then dry it for later use.

[0118] 2) Weigh a certain amount of boric acid, ascorbic acid, ferrous sulfate heptahydrate and PEG20000, dissolve them in deionized water, and prepare the required electrolyte. Wherein the molar concentration of boric acid is 0.2mol . L -1 ; The molar concentration of ascorbic acid is 0.0006mol . L -1 ; The molar concentration of ferrous sulfate heptahydrate is 0.2mol . L -1 ; The molar concentration of PEG20000 is 0.0012mol . L -1 .

[0119] A three-electrode electrolysis system composed of FTO conductive glass, graphite electrode, Ag / AgCl electrode and the above-mentioned electrolyte is adopted, and a step voltage deposition process is used to generate electricity on the surface of FTO conductive glass by changing the applied voltage between FT...

Embodiment 3

[0123] Preparation of Fe by step voltage 2 o 3 film

[0124] 1) Use acetone and deionized water to ultrasonically clean the FTO conductive glass, repeat it several times until it is cleaned, and then dry it for later use.

[0125] 2) Weigh a certain amount of boric acid, ascorbic acid, ferrous sulfate heptahydrate and PEG20000, dissolve them in deionized water, and prepare the required electrolyte. Wherein the molar concentration of boric acid is 0.2mol . L -1 ; The molar concentration of ascorbic acid is 0.0006mol . L -1 ; The molar concentration of ferrous sulfate heptahydrate is 0.2mol . L -1 ; The molar concentration of PEG20000 is 0.0012mol . L -1 .

[0126] A three-electrode electrolysis system composed of FTO conductive glass, graphite electrode, Ag / AgCl electrode and the above-mentioned electrolyte is adopted, and a step voltage deposition process is used to generate electricity on the surface of FTO conductive glass by changing the applied voltage between FT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com