Concrete and preparation method thereof

A concrete and retarder technology, which is applied in the manufacture of rayon, single-component polyester rayon, and fiber chemical characteristics, can solve the problems of limited pore-causing effect of foaming agent and insignificant improvement of concrete surface cracks, etc. , to achieve the effects of strong ductility and fluidity, avoiding the reduction of slump, and improving the ability to resist temperature stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

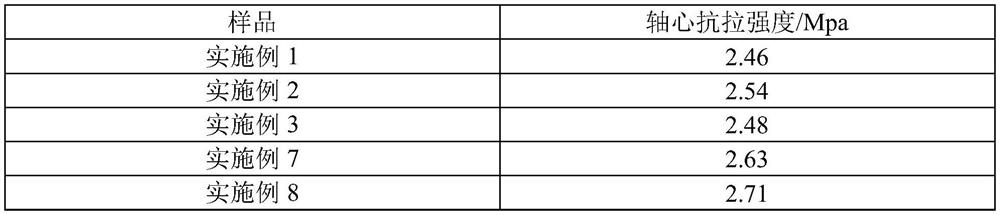

Examples

preparation example 1

[0037] The preparation method of the far-infrared fiber / nano-titanium nitride / PET composite material is:

[0038] (1) Disperse 30%wt nano-titanium nitride in ethylene glycol, mix terephthalic acid and antimony trioxide uniformly and add to the polymerization kettle, the quality of ethylene glycol, terephthalic acid, antimony trioxide The ratio is 1:2.75:0.02. After the polymerization tank is sealed, pressurize to 0.25MPa, heat up to 250°C, stir at 100r / min, and perform esterification for 1.5h to obtain an intermediate product;

[0039] (2) Carry out polycondensation treatment on the intermediate product, make the vacuum degree rise to 20Pa, control the temperature at 270°C, adjust the stirring speed to 240r / min, react for 1.5h, and prepare the nano-titanium nitride / PET polycondensate;

[0040] (3) the pressure is adjusted back to normal pressure, the temperature is adjusted to 50°C, the stirring speed is adjusted to 130r / min, and the far-infrared ceramic powder accounting for ...

preparation example 2

[0042] The preparation method of far-infrared fiber / PET composite material is:

[0043](1) Put PET into the reaction kettle, adjust the pressure to normal pressure, and heat it to a molten state;

[0044] (2) Adjust the stirring speed to 130r / min, and add the far-infrared ceramic powder into the molten PET, stir and mix evenly, discharge the material, cool and granulate, and then spin the masterbatch to obtain the far-infrared fiber / PET composite Material.

Embodiment 1

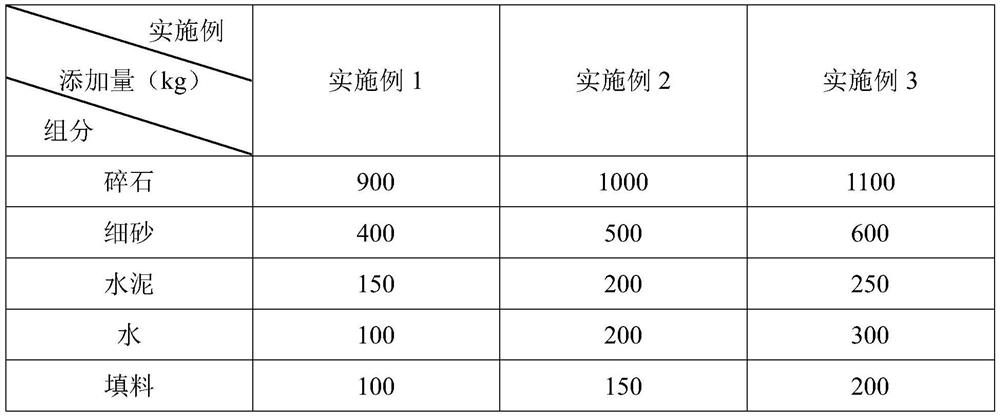

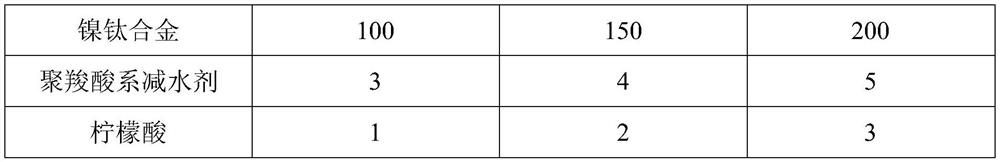

[0047] A kind of concrete, its raw material and portion are as shown in table 1;

[0048]

[0049]

[0050] Among them, the filler includes fly ash, xanthan gum and slag powder with a mass ratio of 1:1:1.5;

[0051] The concrete preparation method specifically comprises the following steps:

[0052] S1. Weigh gravel, fine sand, cement, water, filler, nickel-titanium alloy, water reducer and retarder by weight for subsequent use;

[0053] S2. Stir the crushed stone, fine sand and cement evenly to make a mixed dry material;

[0054] S3. Then add water and water reducer to the mixed dry material, stir for 10 minutes, add filler and nickel-titanium alloy, continue stirring for 5 minutes, add retarder, and mix evenly to obtain a finished concrete product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com