Method for preparing tantalum oxide nanospheres

A technology of tantalum oxide and nanospheres, which is applied in the field of nanomaterials, can solve problems such as complicated product synthesis routes, environmental pollution, and high risk of HF, and achieve the effects of low production cost, good repeatability, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

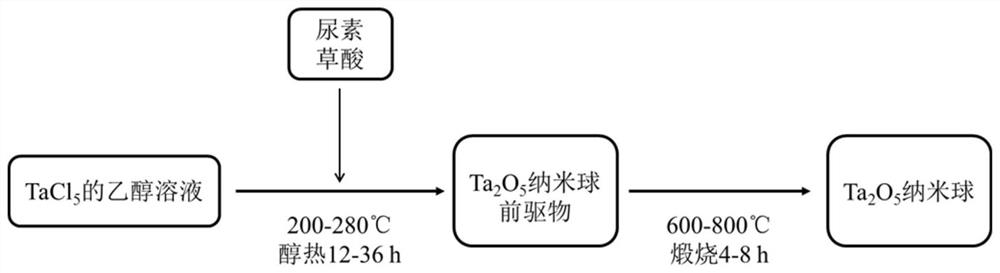

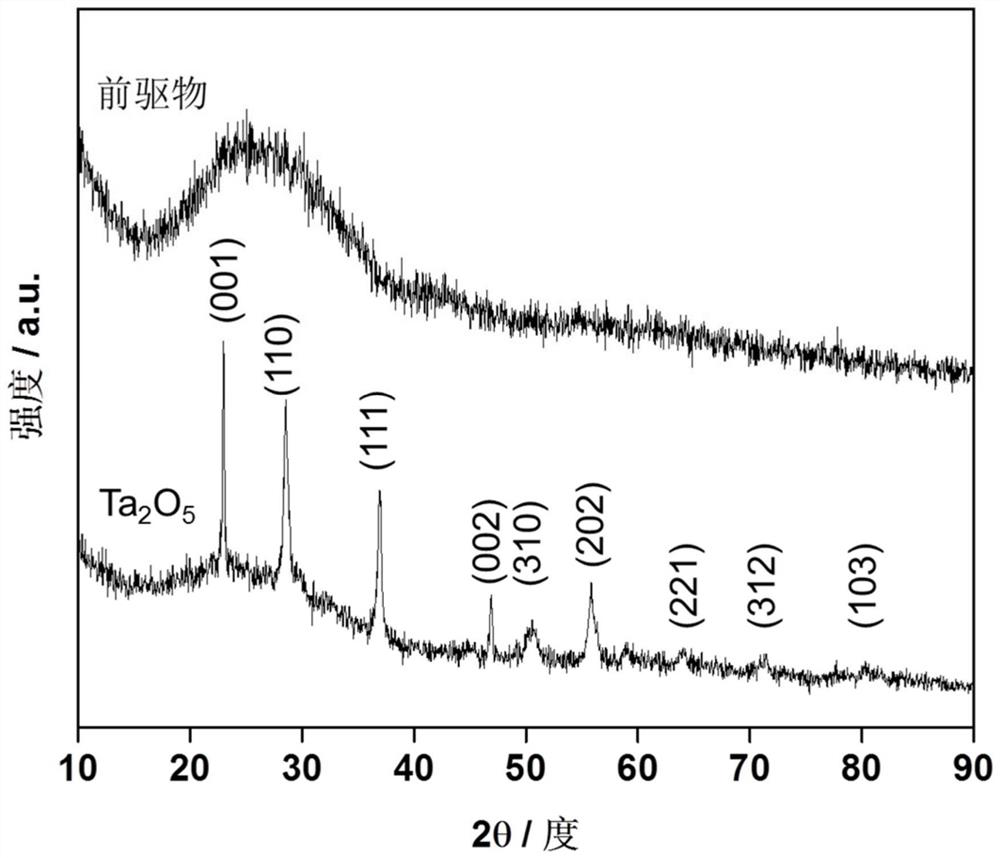

[0048] Such as figure 1 As shown, Example 1 proposes a method for preparing tantalum oxide nanospheres by a template-free method, which specifically includes the following steps:

[0049] a: Ta 2 o 5 Preparation of nanosphere precursors

[0050] a1: Weigh 0.05mmol of TaCl 5 The raw materials were dissolved in 15mL of ethanol and mixed well.

[0051] a2: Add urea and oxalic acid to the ethanol solution of tantalum chloride, the substance ratio of tantalum chloride and urea is 1:10, and the substance ratio of tantalum chloride and oxalic acid is 1:5, stir well to mix the solution uniform.

[0052] a3: Transfer the mixed solution into an autoclave for alcohol thermal reaction, the hydrothermal temperature is 260°C, and the hydrothermal time is 12h.

[0053] a4: The precipitate obtained from the alcohol thermal reaction was centrifuged at 4000rpm for 8min, and dried at 60°C for 4h. get it 2 o 5 Nanosphere precursors.

[0054] b: Ta 2 o 5 Preparation of nanospheres

[...

Embodiment 2

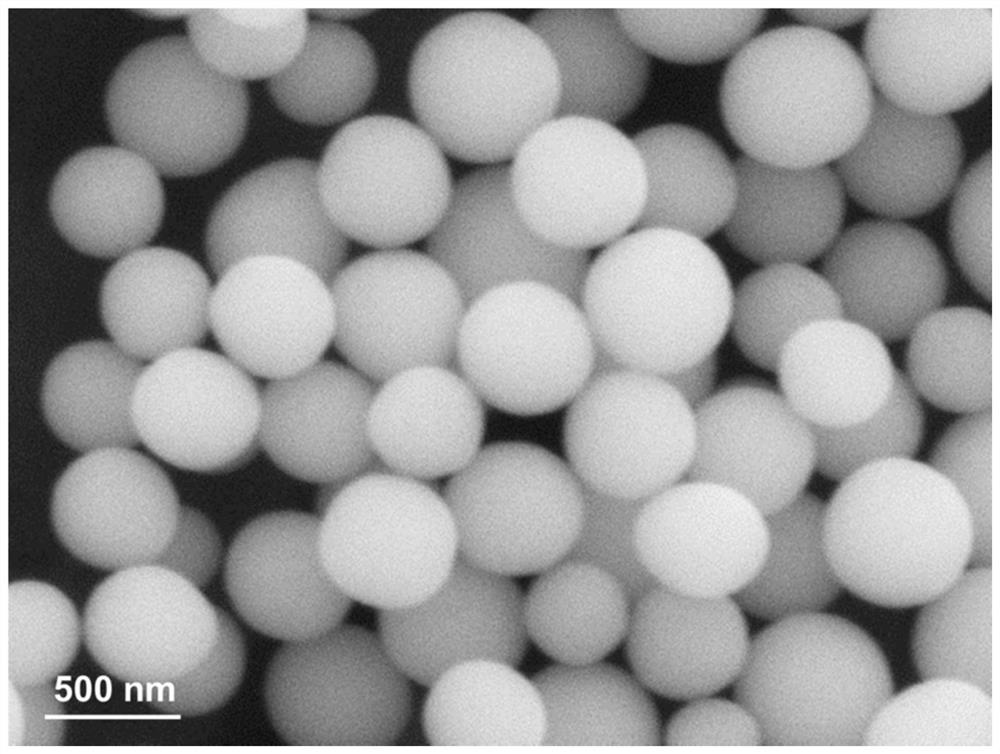

[0059] This embodiment provides a Ta 2 o 5 The preparation method of nanosphere, other conditions are identical with embodiment 1, just with TaCl 5 The amount added was changed to 0.2 mmol. The experimental results are almost the same as in Example 1, and the Ta with a diameter of 300-400nm 2 o 5 nanospheres.

[0060] This shows that TaCl 5 The initial addition amount between 0.01-0.2mmol has no significant effect on the morphology of the product.

Embodiment 3

[0062] This embodiment provides a Ta 2 o 5 The preparation method of nanospheres, other conditions are the same as in Example 1, except that the reaction temperature is changed to 200°C and 280°C. The experimental results are almost the same as in Example 1, and the Ta 2 o 5 nanospheres.

[0063] This shows that the reaction temperature has no significant effect on the product morphology in the range of 200°C-280°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com