Hydrogen fluoride gadolinium oxide as well as preparation method and application thereof

A technology of gadolinium oxide and hydrogen fluoride, applied in the field of materials, can solve the problems of destroying the ozone layer and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

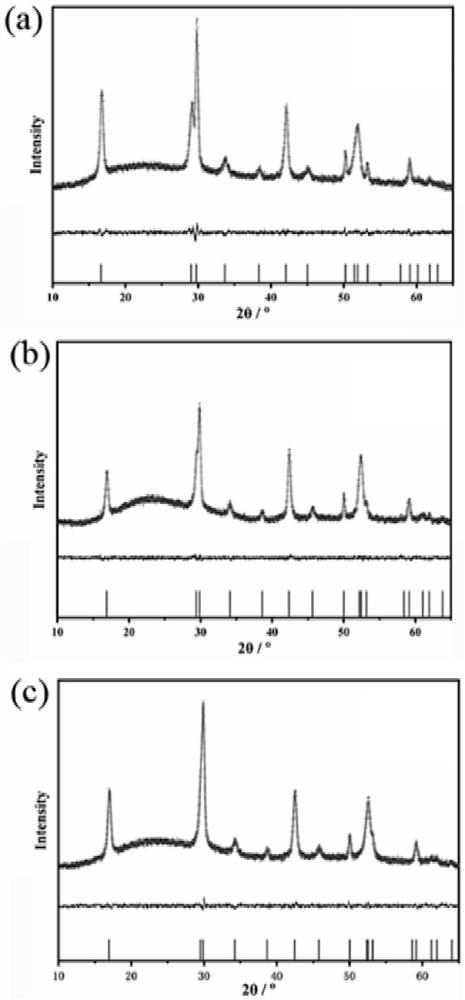

Embodiment 1

[0074] (1) Add GdCl to 5ml of water 3 (0.371g, 1.0mmol) and HF solution (0.043mL, containing HF 1mmol) to obtain a mixed solution;

[0075] (2) Add NaOH aqueous solution (2.5mol L -1 ) to a system pH of about 7.

[0076] (3) The above product was transferred to a polytetrafluoroethylene-lined pressure-resistant stainless steel reactor with a volume of 25 mL, heated to 200° C., and kept at this temperature for 3 days (72 hours). After hydrothermal treatment, the obtained product was separated from solid and liquid, and the solid was collected, washed three times with deionized water, and then air-dried at 100° C. overnight to obtain the solid material of Example 1.

Embodiment 2

[0078] The difference between Example 2 and Example 1 is that the HF aqueous solution used in step (1) has a volume of 0.066 mL, which is equivalent to containing 1.5 mmol of HF.

[0079] Other steps and parameters are the same as in Example 1 to obtain the solid material in Example 2.

Embodiment 3

[0081] The difference between Example 3 and Example 1 is that the HF aqueous solution used in step (1) has a volume of 0.086 mL, which is equivalent to containing 2 mmol of HF.

[0082] Other steps and parameters are the same as in Example 1 to obtain the solid material in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com