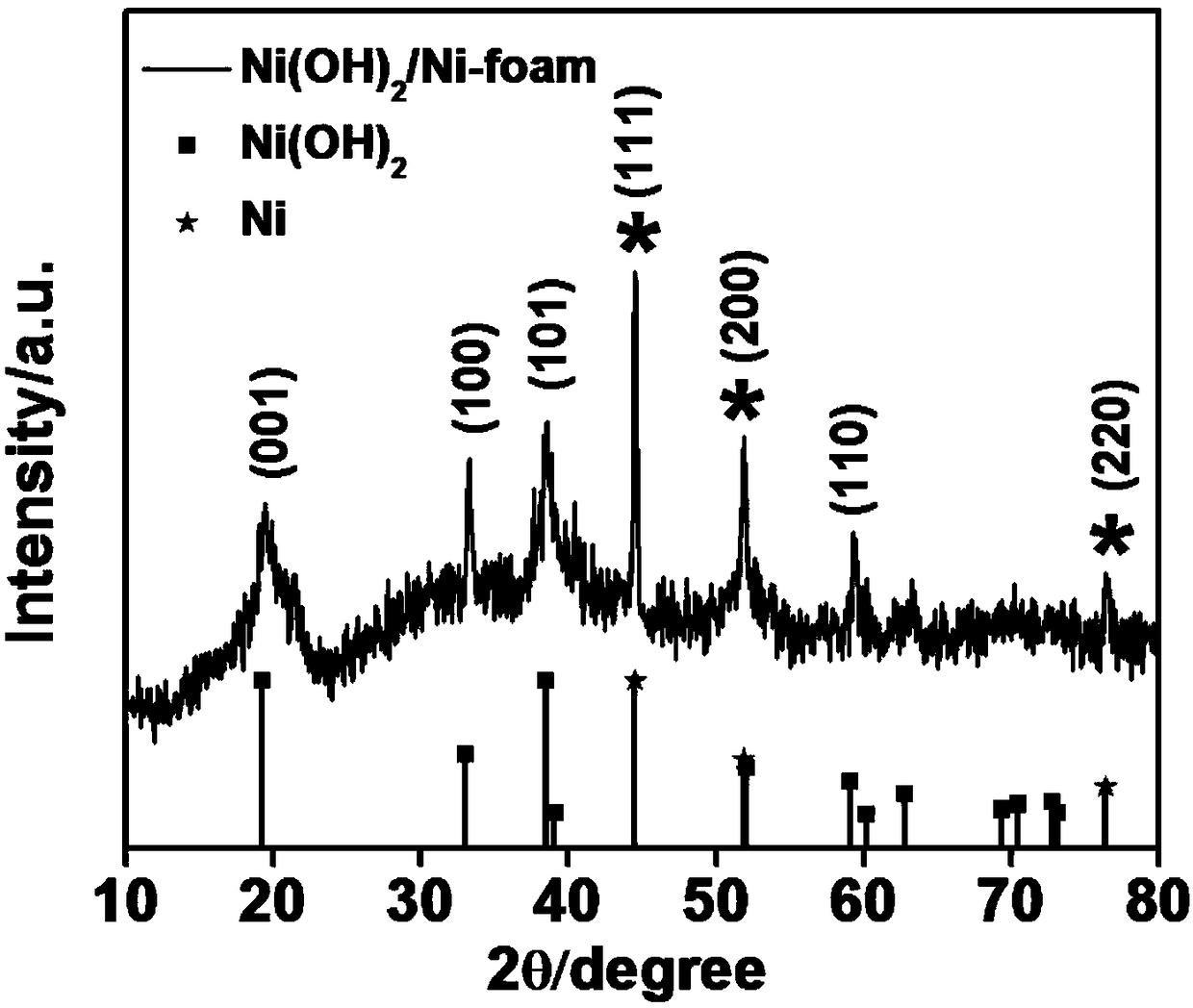

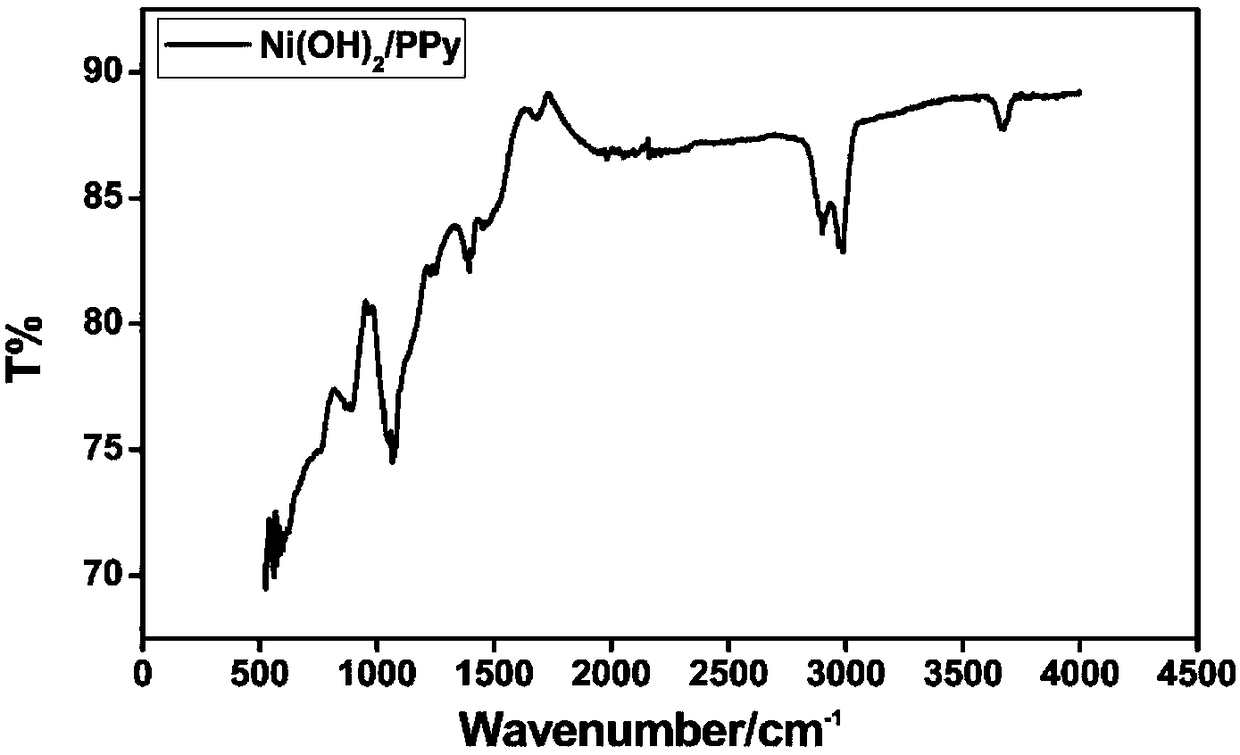

A polypyrrole/nickel hydroxide/nickel foam integrated electrode and its preparation method

A technology of nickel hydroxide and polypyrrole, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor conductivity, unsatisfactory performance, poor cycle performance, etc., and achieve good and controllable morphology , the synthesis method is convenient and fast, and the effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the first step, weigh 0.1792g of nickel acetate hexahydrate and add it to 40ml of ethanol, stir to dissolve;

[0039] In the second step, immerse the pretreated clean nickel foam substrate in the solution obtained in step 2, and place it in a constant temperature water bath at 60°C for 45 minutes;

[0040] The third step is to calcinate the obtained product in the second step in a tube furnace, the calcining temperature is 275°C, the time is 30min, and the heating rate is 2°Cmin -1 ;

[0041] The fourth step, repeat the first step to the third step 2 times;

[0042] In the fifth step, 0.0873g of nickel nitrate hexahydrate and 0.0845g of hexamethylenetetramine are added to 50ml of deionized water to form a mixed solution, and the substrate obtained in the fourth step is immersed in the solution;

[0043] In the sixth step, transfer the solution in the fifth step to a hydrothermal reaction kettle and react at 120°C for 18 hours. After the reaction is completed and cool...

Embodiment 2

[0048] In the first step, weigh 0.1792g of nickel acetate hexahydrate and add it to 40ml of ethanol, stir to dissolve;

[0049] In the second step, immerse the pretreated clean nickel foam substrate in the solution obtained in step 2, and place it in a constant temperature water bath at 60°C for 45 minutes;

[0050] The third step is to calcinate the obtained product in the second step in a tube furnace, the calcining temperature is 275°C, the time is 30min, and the heating rate is 2°Cmin -1 ;

[0051] The fourth step, repeat the first step to the third step 2 times;

[0052] In the fifth step, 0.1745g of nickel nitrate hexahydrate and 0.0845g of hexamethylenetetramine are added to 50ml of deionized water to form a mixed solution, and the substrate obtained in the fourth step is immersed in the solution;

[0053] In the sixth step, transfer the solution in the fifth step to a hydrothermal reaction kettle and react at 120°C for 18 hours. After the reaction is completed and co...

Embodiment 3

[0059] In the first step, weigh 0.1792g of nickel acetate hexahydrate and add it to 40ml of ethanol, stir to dissolve;

[0060] In the second step, immerse the pretreated clean nickel foam substrate in the solution obtained in step 2, and place it in a constant temperature water bath at 60°C for 45 minutes;

[0061] The third step is to calcinate the obtained product in the second step in a tube furnace, the calcining temperature is 275°C, the time is 30min, and the heating rate is 2°Cmin -1 ;

[0062] The fourth step, repeat the first step to the third step 2 times;

[0063] In the fifth step, 0.1745g of nickel nitrate hexahydrate and 0.0845g of hexamethylenetetramine are added to 50ml of deionized water to form a mixed solution, and the substrate obtained in the fourth step is immersed in the solution;

[0064] In the sixth step, transfer the solution in the fifth step to a hydrothermal reaction kettle and react at 120°C for 18 hours. After the reaction is completed and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com