Top and bottom cover assembling device for inner box

A technology for assembling devices and lids, applied in packaging, transportation and packaging, box making operations, etc., can solve problems such as the increase in the area of the mechanical device, the increase in the size of the turntable, and the impact on the completion efficiency of other processes. The effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

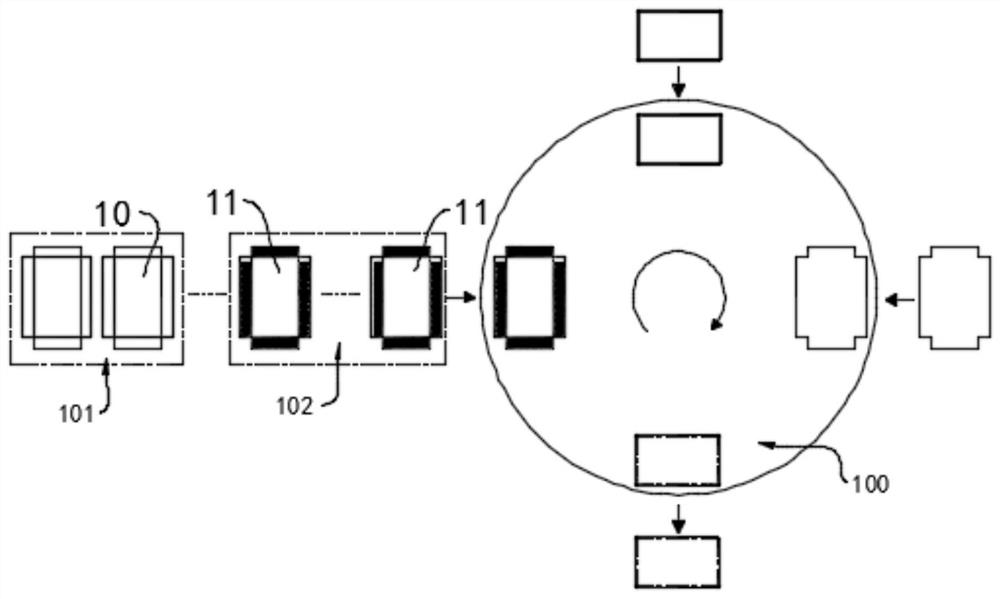

[0043] like figure 1 As shown, in the manufacturing process of the inner box of the fully open cigarette pack small box, an inner box machine is used to make the inner box. The corresponding processing mechanism is arranged on the outer side of the circumference to target the materials on the carrier, and the position where the materials stop and process in this area is the station. Eight stations are set around the main body of the turntable: floor cover silo, floor cover gluing, enclosure inner mold assembly assembly, sky cover feeding and discharge station.

[0044] Among them, the ground cover material warehouse station 101 is used to store the ground cover incoming material 10, and the ground cover incoming material enters the carrier of the turntable main body 100 from this station; then, the turntable main body turns an angle, and the carrier carries the ground cover incoming material Enter the floor cover gluing station 102, a gluing device is installed next to the tu...

Embodiment 2

[0064] like Figure 7 With reference to the foregoing embodiments, it can be understood that the carrier of the above-mentioned sky and earth cover assembly device for the inner box may also be a linear conveyor belt. Also, the efficiency of the inner box can be improved.

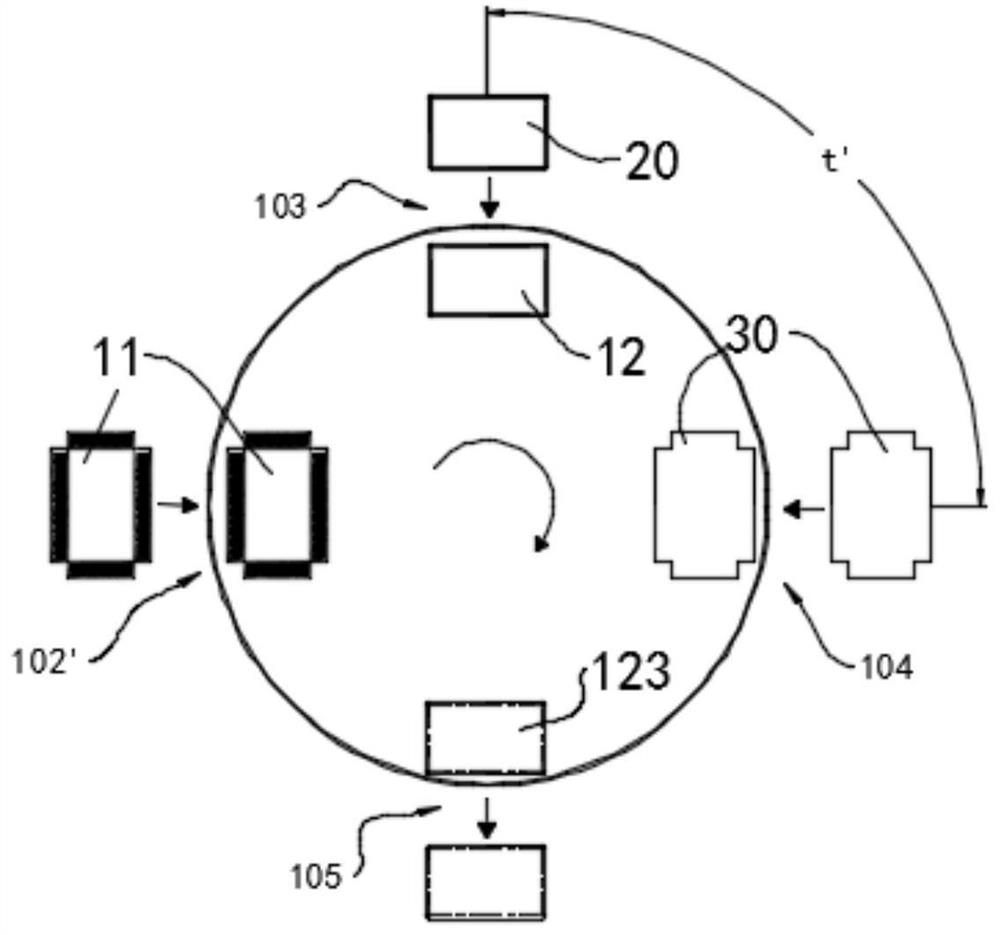

[0065] Corresponding ground cover loading station 102 ′, enclosure assembly station 103 , sky cover feeding station 104 , and discharge station 105 are arranged on both sides or one side of the conveyor belt. The rest are the same as those in the above-mentioned embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com