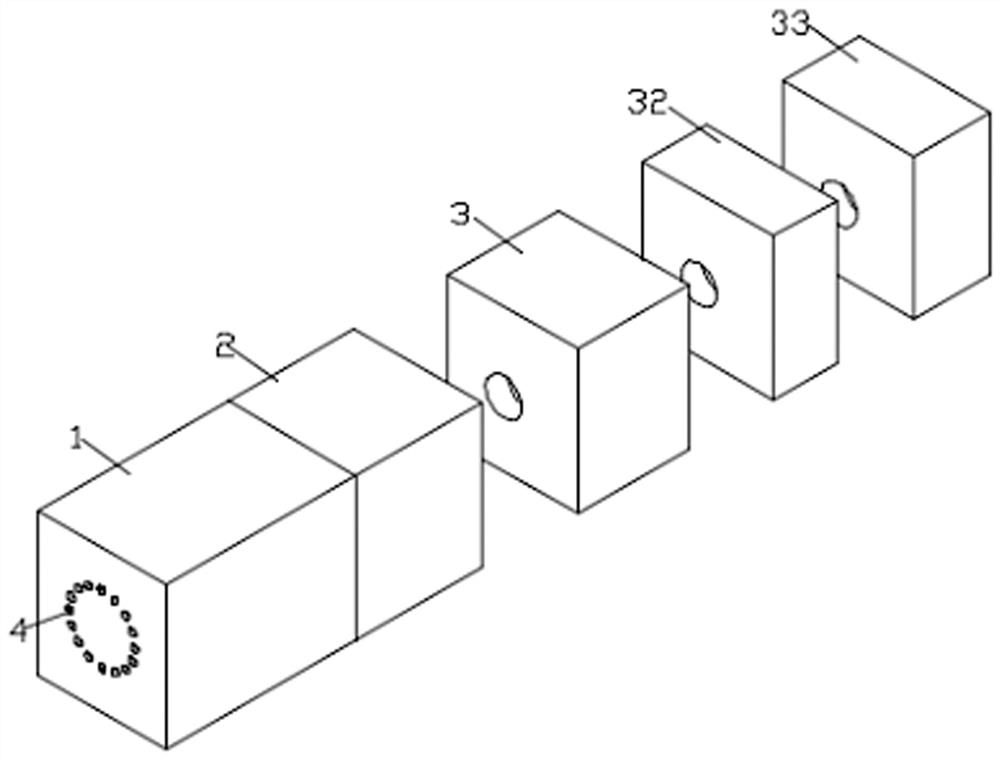

Copper wire production process capable of reducing oxidation and production line thereof

A production process and production line technology, which is applied in the field of copper wire production process and its production line, can solve the problems of steel wire oxidation and low processing efficiency, and achieve the effects of reducing oxidation, improving wire drawing effect, and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

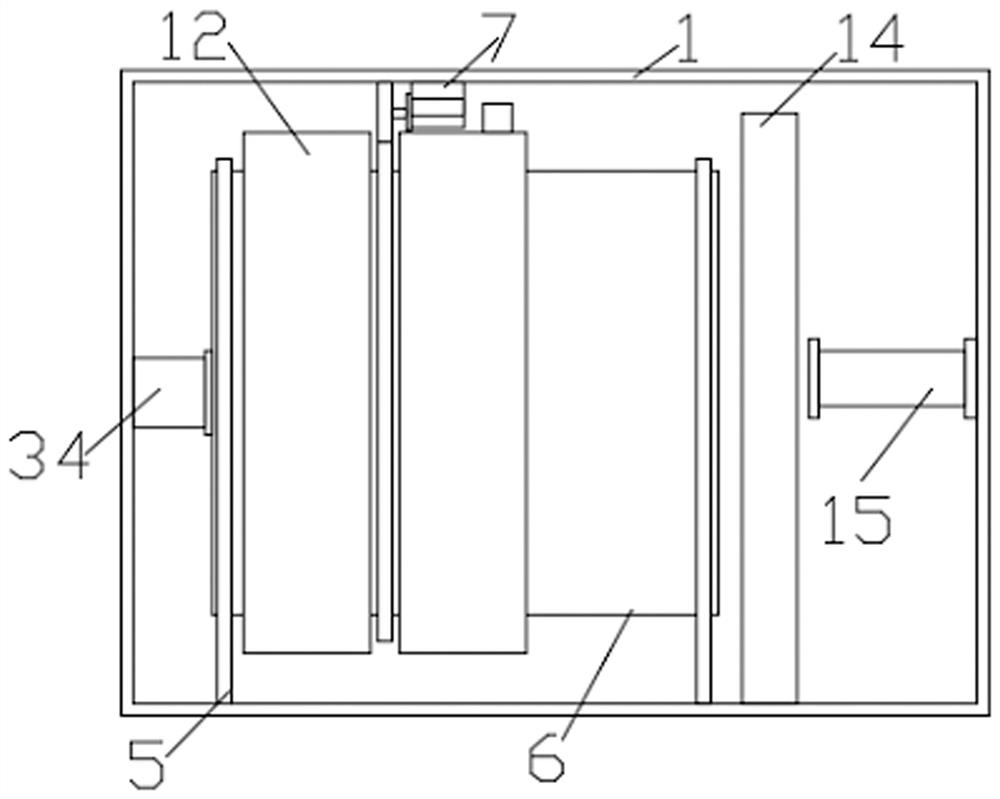

[0034] A copper wire production process capable of reducing oxidation, comprising the steps of:

[0035] Step 1: A number of copper wires enter the processing chamber 1 through the corresponding inlet and outlet 4 on the processing chamber 1 in the production line. The copper wires pass through the turnover drum 6 and turn on the turnover motor 7. The output shaft of the turnover motor 7 drives the gear to rotate, and the gear matches the gear ring Drive the turnover drum 6 to rotate, turn on the drive motor 34, the output shaft of the drive motor 34 drives the drive rod 35 to rotate, the drive rod 35 drives the scraper disc 36 and the second absorbent cotton 37 to rotate, and the nozzle 11 on the second installation pipe 9 turns the storage shell The pickling solution in 12 is sprayed on the surface of some copper wires, the pickling solution removes the oxide on the surface of the copper wires, and then some copper wires pass between the scraper ring 10 and the scraper disc 3...

Embodiment 2

[0040] A copper wire production process capable of reducing oxidation, comprising the steps of:

[0041] Step 1: A number of copper wires enter the processing chamber 1 through the corresponding inlet and outlet 4 on the processing chamber 1 in the production line. The copper wires pass through the turnover drum 6 and turn on the turnover motor 7. The output shaft of the turnover motor 7 drives the gear to rotate, and the gear matches the gear ring Drive the turnover drum 6 to rotate, turn on the drive motor 34, the output shaft of the drive motor 34 drives the drive rod 35 to rotate, the drive rod 35 drives the scraper disc 36 and the second absorbent cotton 37 to rotate, and the nozzle 11 on the second installation pipe 9 turns the storage shell The pickling solution in 12 is sprayed on the surface of some copper wires, the pickling solution removes the oxide on the surface of the copper wires, and then some copper wires pass between the scraper ring 10 and the scraper disc 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com