Bamboo-wood composite-based high-strength ecological bamboo core board and machining method thereof

A bamboo-wood composite and processing method technology, applied in wood processing appliances, wood heating, wood veneer bonding, etc., can solve problems such as limited performance of household products, achieve sustainable development of the environment, and improve utilization. , the effect of enhancing surface performance and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

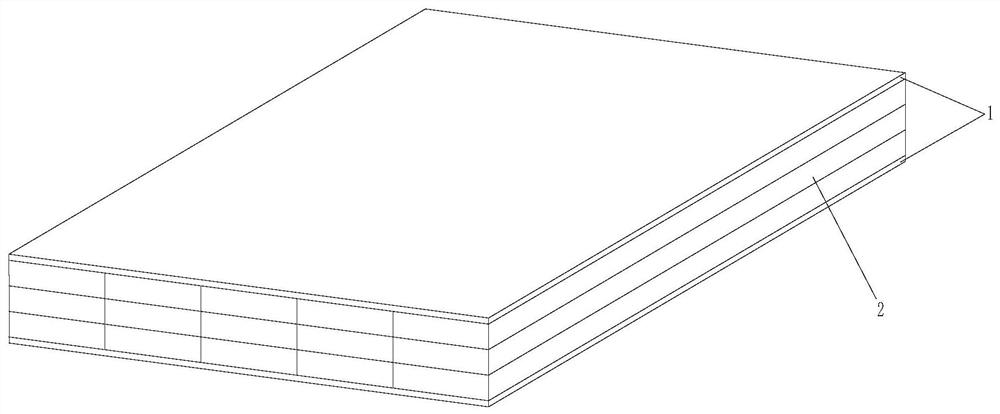

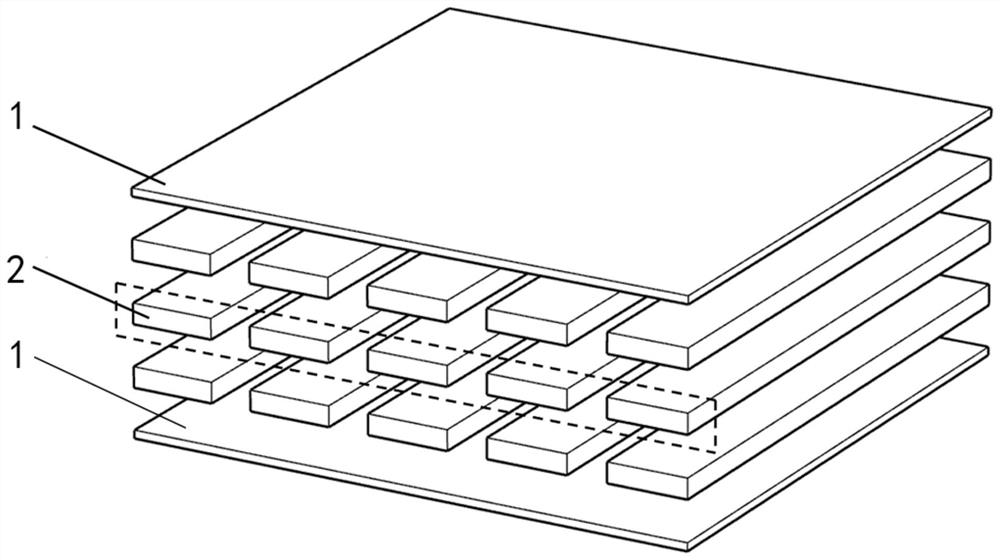

[0051] Such as figure 1 or figure 2 As shown, the present embodiment is a kind of high-strength ecological bamboo core board based on bamboo and wood composite, comprising a pair of relatively arranged ecological board layers 1, a bamboo core that is arranged between a pair of ecological board layers 1 and has 3 layers Layer 2, wherein, between the adjacent bamboo core layers 2, between the bamboo core layer 2 and the ecological board layer 1, all fit and fix as a whole, in the present embodiment, in addition, each layer of bamboo core layer 2 is several pieces of rectangular The bamboo slices are spliced side by side in an array and fixed into one body. In this embodiment, the rectangular bamboo slices in adjacent bamboo core layers 2 are arranged in the same direction.

[0052] In this embodiment, the ecological board layer 1 is a paint-free board (or specifically a melamine board), and its thickness can be 2 to 3 mm. The end surface of the ecological board layer 1 away ...

Embodiment 2

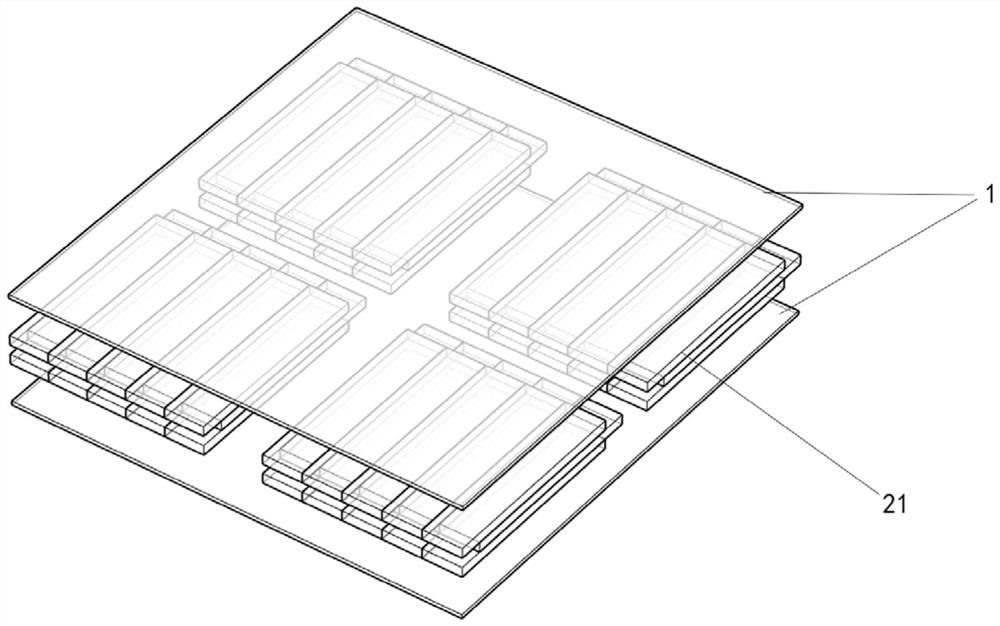

[0055] Such as Figure 3 to Figure 5 One shows that this embodiment is roughly the same as Embodiment 1, and the difference is that, as a possible implementation mode, further, in this embodiment, the number of layers of the bamboo core layer 2 is 3 layers, and the bamboo core layer The core layer 2 is formed by splicing together several prefabricated and spliced bamboo board blanks 21 made of three layers of rectangular bamboo sheets.

[0056] Wherein, among several pieces of bamboo board blanks 21 of the present embodiment, one end of the rectangular bamboo slices in the middle layer is flat or dislocated to form a tenon or tenon groove with the edge of the rectangular bamboo slices in the adjacent layer, and the rectangular bamboo slices in the middle layer are in the other direction. One end and the edge of the rectangular bamboo slices of the adjacent layer are flat or misplaced to form a tenon or a tenon groove, wherein the bamboo board embryo with tenon and the bamboo...

Embodiment 3

[0059] Such as Figure 6 As shown, this embodiment is roughly the same as Embodiment 2, the difference is that in this embodiment, the rectangular bamboo slices in adjacent bamboo core layers 2 are arranged orthogonally to each other.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com