Modular intelligent clean room

A clean room, modular technology, applied in the field of clean room, can solve the problems of inconvenient disassembly and installation, low structural strength, high internal temperature, etc., and achieve the effect of convenient riveting, compact structure and smaller volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

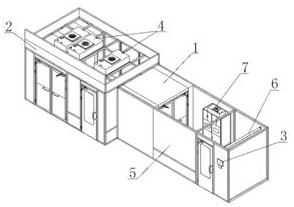

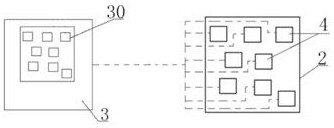

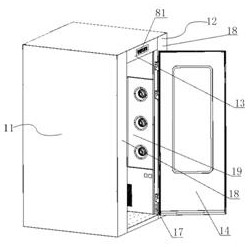

[0081] Refer to attached Figure 1-48 , a modular intelligent clean room, which includes a changing unit, an air shower room 1, and a clean room 2. A changing unit is installed on the entrance side of the clean room 2. The air shower room 1 is located inside the changing unit and the air shower room 1 is installed in the clean room. At the entrance of room 2, the monitoring unit 3 is installed on the outer wall of the entrance of the changing unit. Several fan filter units 4 are installed on the top of the clean room 2. The monitoring unit 3 is designed to be installed on the outside of the clean room 2 or clean room 2 Inside the room and the monitoring unit 3 is connected to several fan filter units 4 through signal lines; the monitoring unit 3 is designed to monitor several fan filter units 4 and display that several fan filter units 4 are arranged one by one on the top of the clean room 2 Cloth display unit 30; the dressing unit includes a dressing room 5, a hanger 6, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com