Nanogold catalyst as well as preparation method and application thereof

A technology of catalyst and oxidative esterification, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instrument and method, etc., and can solve problems such as unfavorable industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

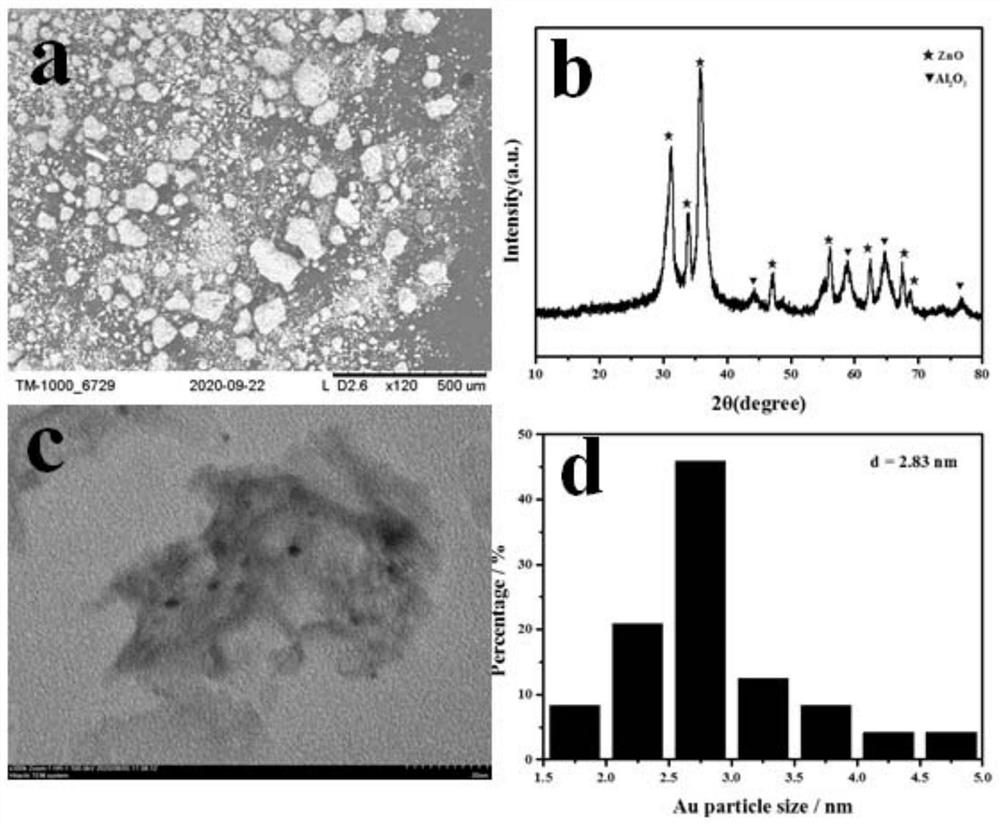

Image

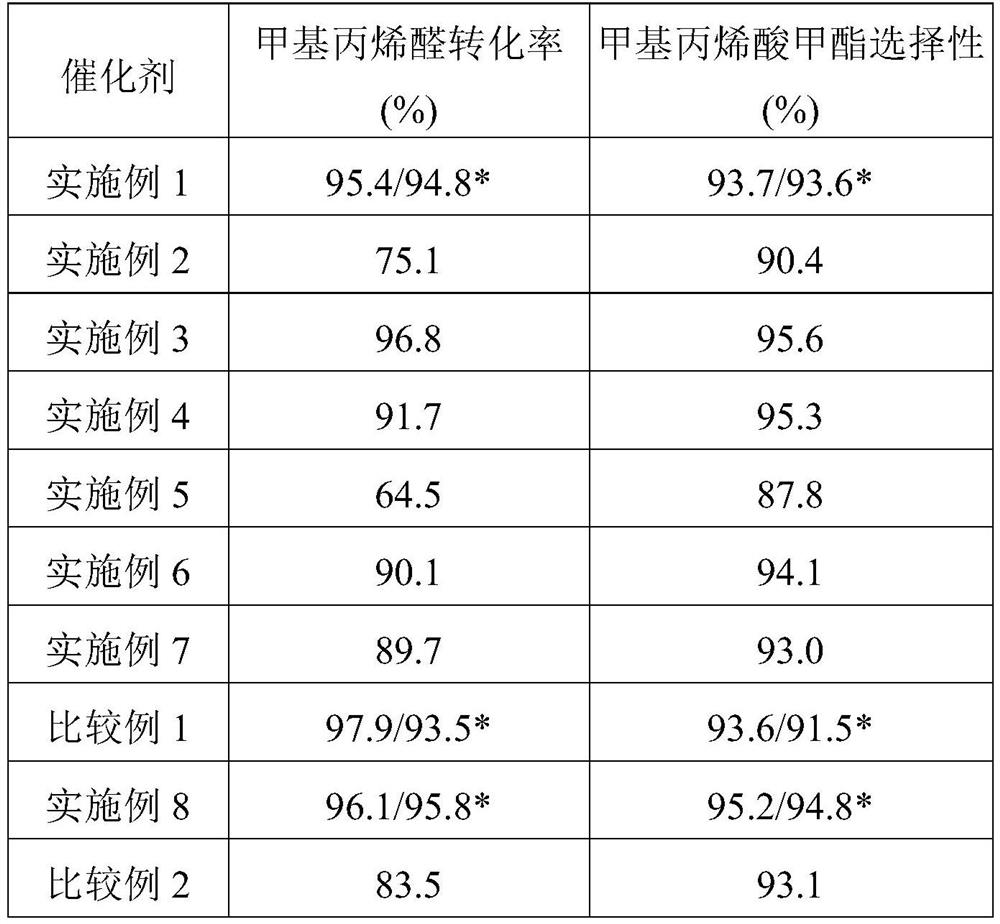

Examples

preparation example Construction

[0040] The invention also relates to a method for the preparation of the catalyst. The preparation method of catalyst of the present invention comprises the steps:

[0041] a) dissolving the aluminum source, zinc source, cobalt source and / or lanthanum source into a solution according to the required molar ratio

[0042] The solvent suitable for forming the solution is not particularly limited, but water is preferred from the viewpoints of cost and environmental protection.

[0043] The aluminum source, zinc source, cobalt source and / or lanthanum source suitable for the method of the present invention are not particularly limited, as long as they can form a solution in water. In one example of the present invention, the aluminum source is selected from aluminum nitrate, aluminum chloride, aluminum sulfate or a mixture thereof, preferably aluminum nitrate.

[0044] In one example of the present invention, the zinc source is selected from zinc nitrate, zinc chloride, zinc sulfate...

Embodiment 1

[0084] Weigh 23.80g of zinc nitrate hexahydrate, 30.01g of aluminum nitrate nonahydrate and 1.04g of cobalt nitrate hexahydrate and dissolve them in 80mL of deionized water, stir for 15 minutes to form solution A, and weigh 12.80g of Sodium and 6.78g of sodium carbonate were dissolved in 80mL of deionized water and stirred for 15-30 minutes to form solution B. Slowly add solution B to solution A, and age at 70°C for 10 hours, filter, wash and dry, and bake in a muffle furnace at 600°C for 5 hours to obtain about 10.8g of the carrier, which is ground and sieved to obtain 100-200 mesh granules are ready for use.

[0085] Weigh 0.0659g of chloroauric acid and 3.66g of urea and dissolve them in 30mL of deionized water, stir for 15 minutes, then add 3g of carrier, stir and age in a water bath at 80°C for 6 hours, filter, and wash until there is no chloride ion After detection, oven at 110° C. overnight, and muffle furnace at 300° C. in air for 5 hours, the catalyst was obtained. ...

Embodiment 2

[0089] With embodiment 1, sodium carbonate consumption 20.35g, do not use sodium hydroxide, the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com