Hot fix device for pattern decoration process

A technology of process and installation block, which is applied in the field of hot-drilling devices for graphic decoration, and can solve the problems of uneven cutting surface or spherical surface, high defective rate of acrylic hot-drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

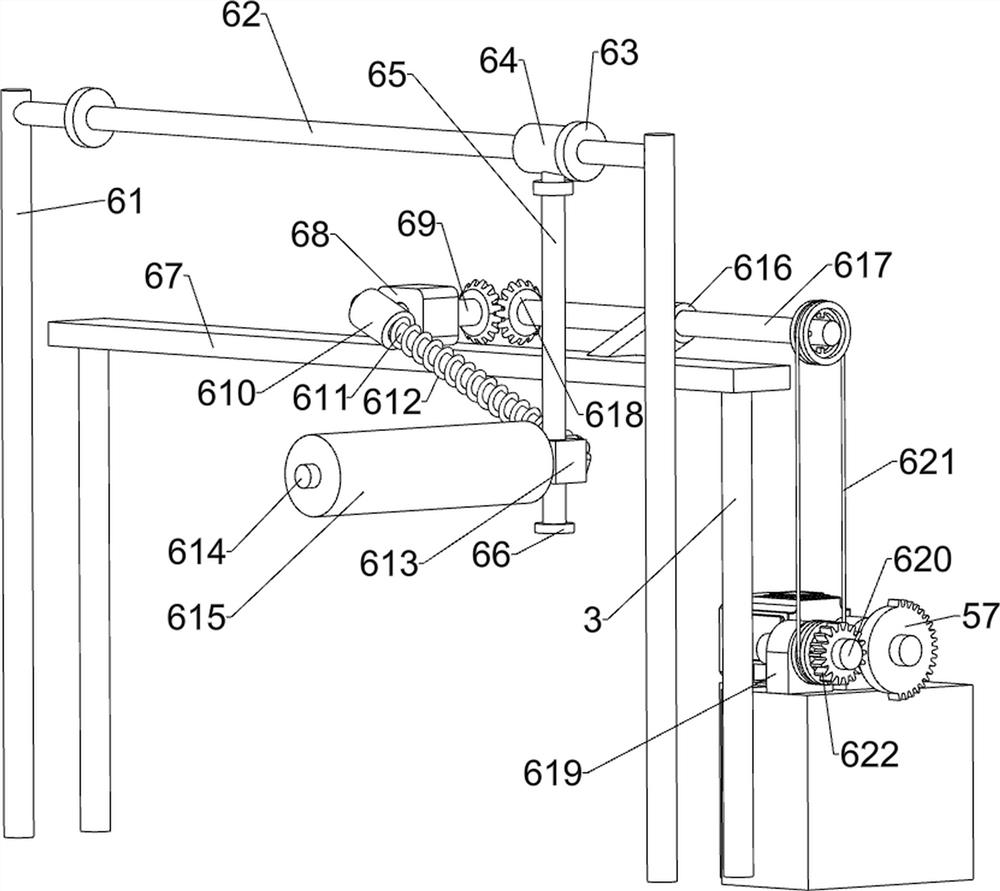

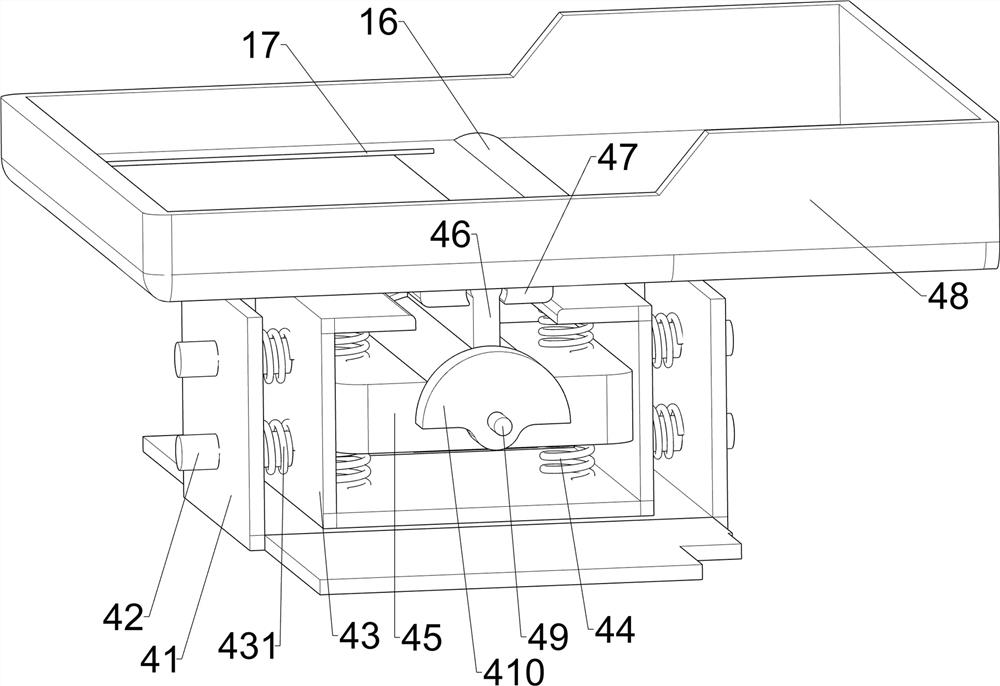

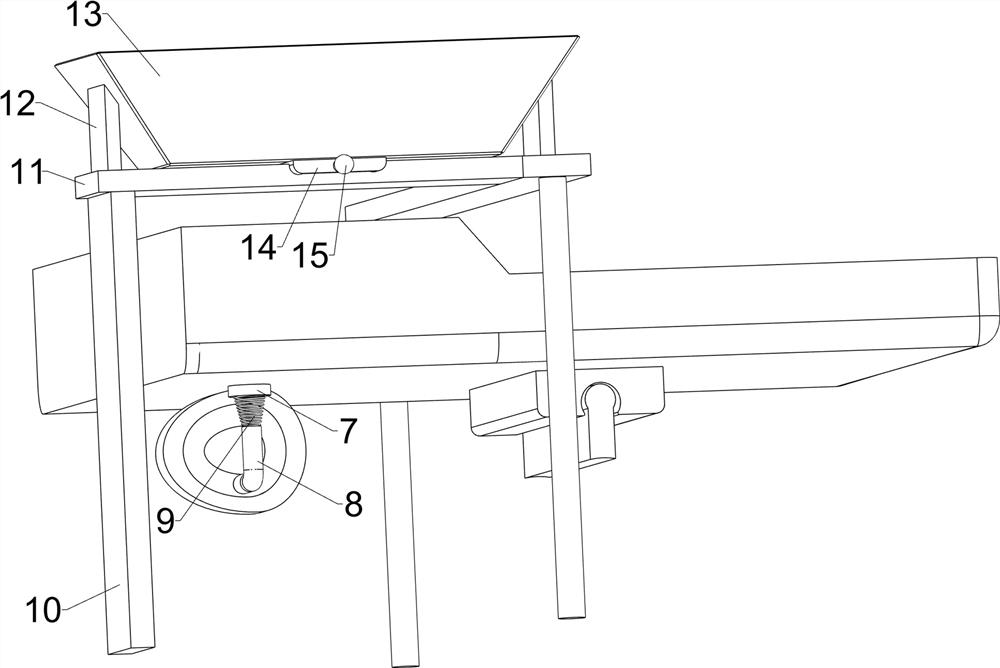

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a ironing device for graphic decoration technology includes a base 1, a mounting block 2, a first support rod 3, an inertial vibration mechanism 4, a tilting mechanism 5 and a rolling sticker mechanism 6, and the right side of the top of the base 1 is provided with a mounting Block 2, the top of the base 1 is located on the left side of the mounting block 2, and the first support rod 3 is symmetrically arranged front and back, the left side of the top of the base 1 is provided with an inertial vibration mechanism 4, and the top of the mounting block 2 is provided with a tilting mechanism 5, and the tilting mechanism 5 and the inertial vibration The mechanism 4 cooperates, and the top of the base 1 is provided with a rolling sticker mechanism 6 above the inertial vibration mechanism 4 .

[0024] Inertial vibrating mechanism 4 comprises fixed plate 41, cross bar 42, N-shaped plate 43, first elastic member ...

Embodiment 2

[0029] Such as figure 2 and Figure 5 As shown, on the basis of Embodiment 1, a ironing device for graphic decoration process also includes a connecting column 7, a positioning rod 8 and a fourth elastic member 9, and the right side of the bottom of the workbench 48 is provided with a connecting column 7, A positioning rod 8 is slidably disposed on the second cam 53 , and a fourth elastic member 9 is disposed between the positioning rod 8 and the connecting column 7 .

[0030] When the second cam 53 rotates and contacts the extruding workbench 48 to drive the workbench 48 to swing back and forth around the top of the rocker 46, the second cam 53 is slidably matched with the positioning rod 8 and under the action of the fourth elastic member 9, the stability of the device is enhanced.

[0031] It also includes a third support rod 10, a horizontal plate 11, a fixed rod 12, a material storage box 13, a bottom plate connection block 14, a pull rod 15, a material retaining block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com