Antibacterial biodegradable composite material as well as preparation method and application thereof

A technology of biodegradable and composite materials, which is applied in the field of antibacterial biodegradable composite materials and its preparation, can solve the problems of high technical content of biodegradable plastics, limited application of biodegradable materials, affecting food preservation period and storage period, etc. To achieve the effect of prolonging the fresh-keeping period of food, inhibiting the reproduction of microorganisms, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In order to solve the technical problems of the above-mentioned background technology, the present invention provides a kind of antibacterial biodegradable composite material and preparation method thereof, specifically,

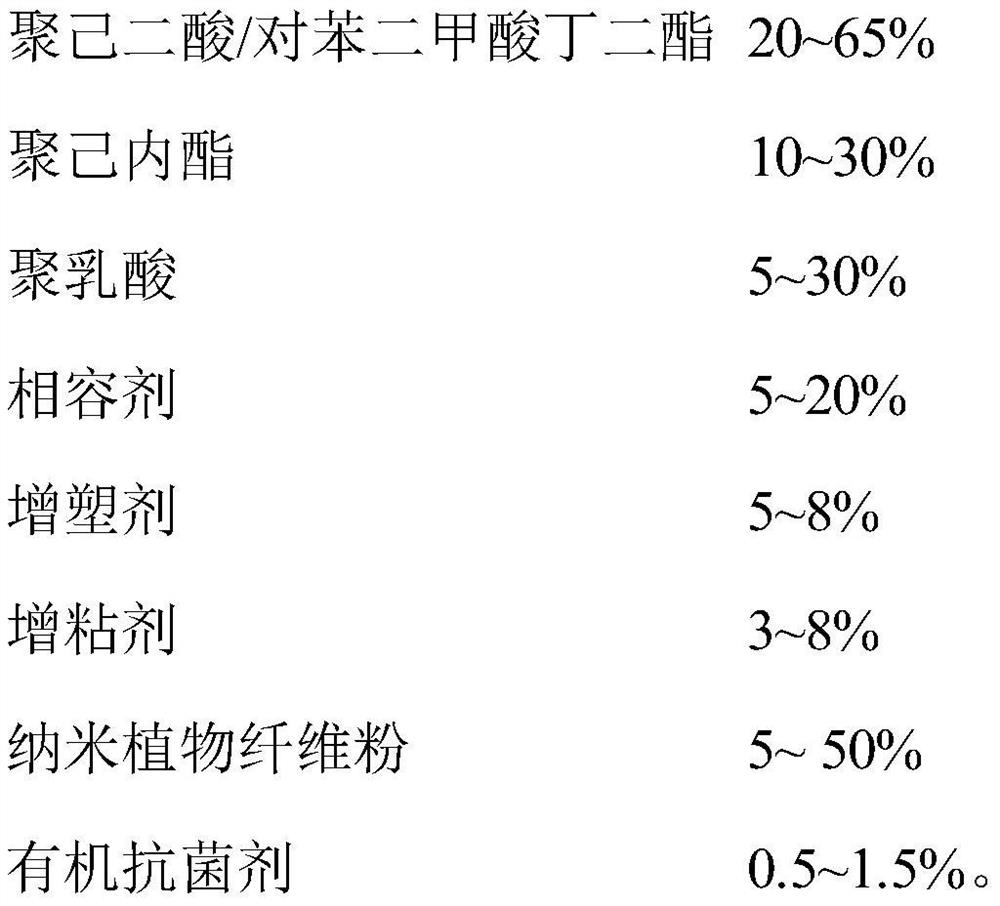

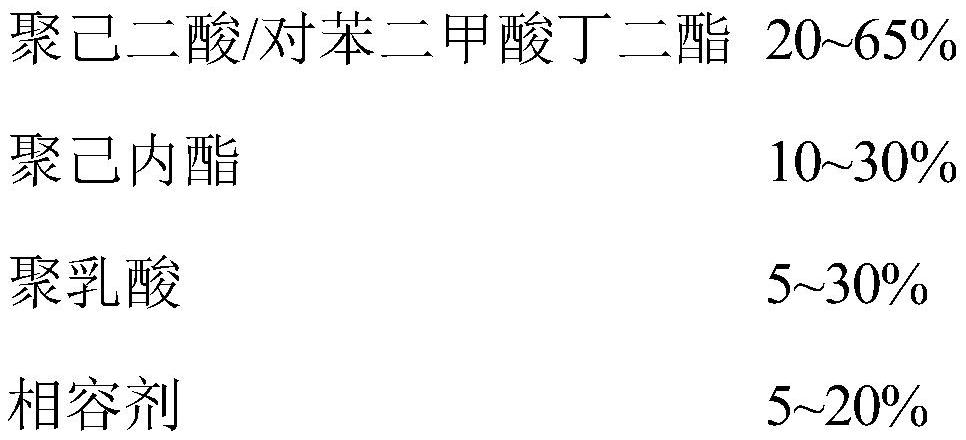

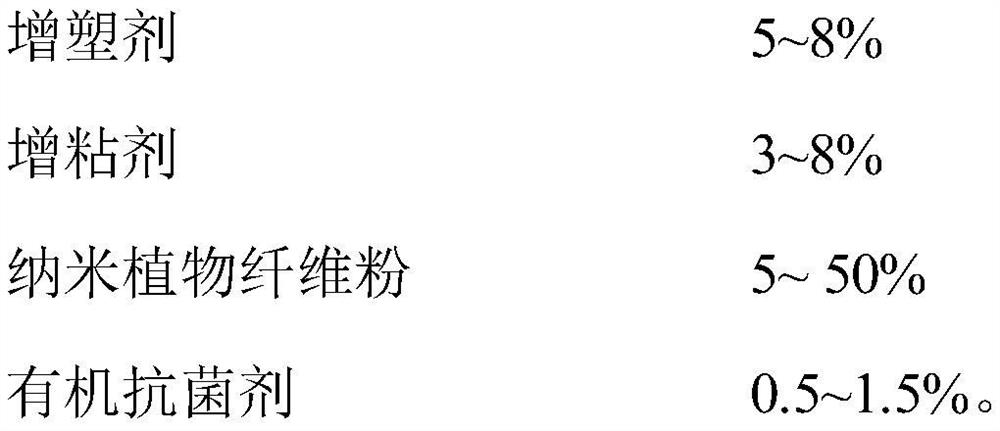

[0024] A kind of biodegradable composite material is mixed in proportion by following raw materials, and described proportion is percentage by weight:

[0025]

[0026] The preparation method of this antibacterial biodegradable composite material, it comprises the following steps:

[0027] (1) the dried plant fiber powder is ground into the nano-scale plant fiber powder of nano-scale fineness in advanced grinder;

[0028] (2) In terms of weight percentage, 20-65% of polybutylene adipate / terephthalate, 10-30% of polycaprolactone, 5-30% of polylactic acid, 5-20% of Compatibilizer, 5-8% plasticizer, 3-8% tackifier, 5-50% nano-plant fiber powder and 0.5-1.5% organic antibacterial agent are added to the mixer and mixed uniformly to obtain Mixture;

...

Embodiment 1

[0040] An antibacterial biodegradable composite material, which is formed by mixing the following raw materials in proportion, and the proportion is percentage by weight: 20% polybutylene adipate / terephthalate, 30% polycaprolactone, 5% polylactic acid, 10% glycidyl methacrylate, 5% glycerin, 4.5% maleic anhydride, 24% nano-plant fiber powder and 1.5% long-chain alkyl quaternary ammonium salt;

[0041] The preparation method of the antibacterial biodegradable composite material comprises the following steps:

[0042] (1) In the high-grade grinder, the dried wood chips, fruit husks, rice husks, and wheat husks are mixed together and ground into nano-scale fineness nano-plant fiber powder;

[0043] (2) In terms of weight percentage, 20% of polyadipate / butylene terephthalate, 30% of polycaprolactone, 5% of polylactic acid, 10% of glycidyl methacrylate, 5% % glycerin, 4.5% maleic anhydride, 24% nano-plant fiber powder and 1.5% long-chain alkyl quaternary ammonium salts are added t...

Embodiment 2

[0047] An antibacterial biodegradable composite material, which is formed by mixing the following raw materials in proportion, and the proportion is percentage by weight: 25% polybutylene adipate / terephthalate, 10% polycaprolactone, 5% polylactic acid, 20% tetrabutyl titanate, 5% acetylated triethyl citrate, 3.8% maleic anhydride, 30% nano plant fiber powder and 1.2% long chain alkyl trimethyl silylpropylammonium chloride;

[0048] The preparation method of the antibacterial biodegradable composite material comprises the following steps:

[0049] (1) Mix and grind dried rice stalks, wheat straw, sorghum stalks, cotton stalks, hemp stalks, and corncob powder into nano-scale fineness nano-plant fiber powder in a high-grade grinder;

[0050] (2) In terms of weight percentage, 25% polybutylene adipate / terephthalate, 10% polycaprolactone, 5% polylactic acid, 20% tetrabutyl titanate, 5% Acetylated triethyl citrate, 3.8% maleic anhydride, 30% nano-plant fiber powder and 1.2% long-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com