1500Mpa-level anti-fatigue electric taxi torsion beam

An anti-fatigue and taxi technology, which is applied to vehicle components, elastic suspensions, cantilever mounted on pivots, etc., can solve the problems affecting the safety of the vehicle, the anti-fatigue life of the torsion beam, the impact on the stability and smoothness of the vehicle, and the torsion beam Reduce the risk of fatigue cracking, optimize the distribution of internal stress, and increase the cruising range to avoid problems such as increased material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

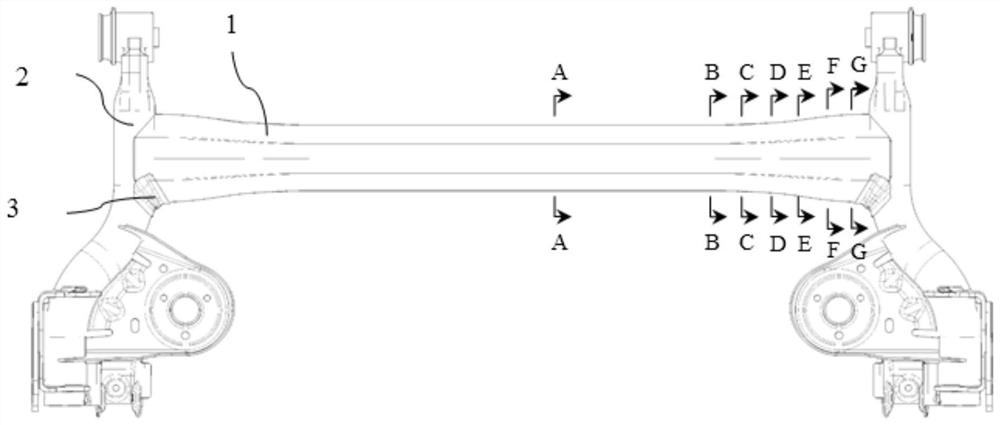

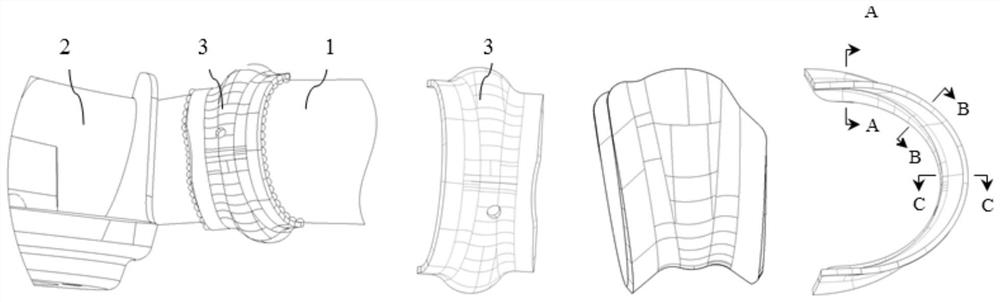

[0039] refer to Figure 1-Figure 7 , a 1500Mpa anti-fatigue electric taxi torsion beam, including a beam 1, a longitudinal arm 2, a reinforcement plate 3, a bushing 4, a spring tray 5, a shock absorber bracket 6, an end plate 7, a wheel side bracket 8 and a bushing 9.

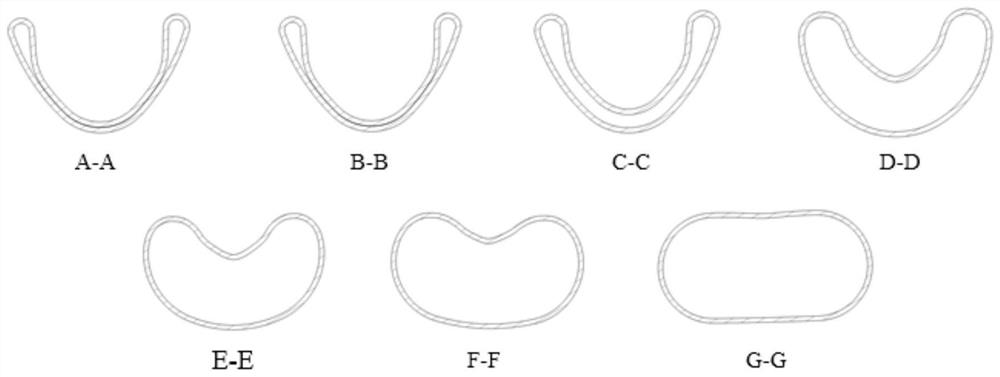

[0040] The structure of the torsion beam beam 1 will directly affect the dynamic performance and fatigue resistance of the vehicle, so the beam 1 is the core component of the torsion beam. The cross beam 1 is a stamped structure of a closed tube beam with equal cross-section and perimeter, and the common transverse stabilizer bar is omitted. Through the special section design of the beam, the internal stress distribution of the stamping forming of the beam and the external stress distribution of the torsion condition are optimized, thereby reducing the risk of fatigue cracking under the common torsion condition of the beam. For the cross-section change of beam 1, see the attachment figure 2 , from attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com