Intelligent smoke exhaust self-cleaning system of baking shaping equipment

A kind of equipment and intelligent technology, applied in the field of textile fabric production, can solve the problems of easy fire, polluted fabric, and many pollutants, and achieve the effect of controllable air volume, high degree of automation, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

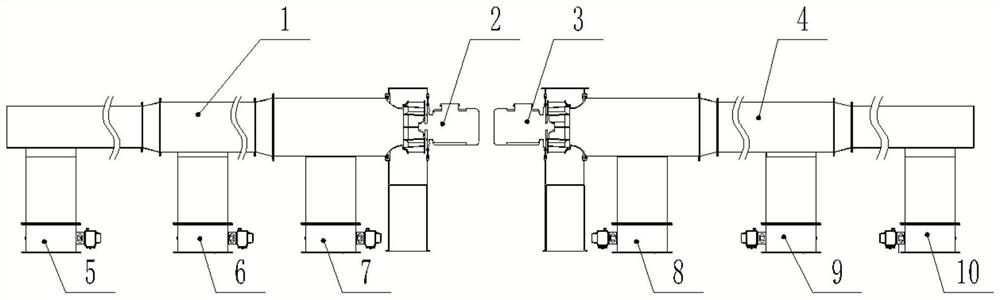

[0033] Such as figure 1 As shown, it is a schematic structural diagram of the intelligent smoke exhaust self-cleaning system of the baking and shaping equipment in Example 1 of the present invention; wherein, 1 is the first smoke exhaust pipe, 2 is the first ultra-high negative pressure fan, and 3 is the second ultra-high negative pressure fan. Negative pressure fan, 4 is the second smoke exhaust pipe, 5 is the first air volume adjustment damper, 6 is the second air volume adjustment damper, 7 is the third air volume adjustment damper, 8 is the fourth air volume adjustment damper, 9 is the fifth air volume adjustment Damper, 10 is the sixth air volume adjustment damper;

[0034] The intelligent smoke exhaust self-cleaning system of baking and setting equipment includes the first smoke exhaust pipe 1, the first ultra-high negative pressure fan 2, the second ultra-high negative pressure fan 3, the second smoke exhaust pipe 4, the first air volume adjustment damper 5, The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com