Roundness measurement method based on two sensors

A roundness measurement and sensor technology, applied in the direction of measuring devices, instruments, etc., can solve the problems that the accuracy and precision cannot be guaranteed, and achieve the effects of improving accuracy and precision, reducing costs, and avoiding lengthy measurement processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with drawings and embodiments.

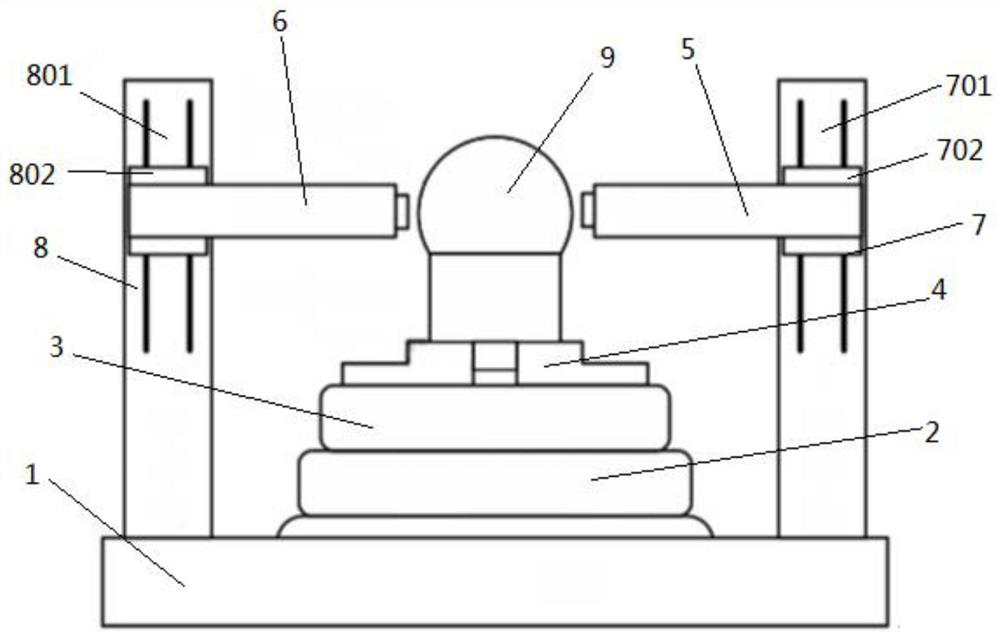

[0042] Such as figure 1The measuring device used in the measurement of the present application includes a base, a first turntable, a second turntable, a chuck, a first displacement sensor and a second displacement sensor, and the first turntable is installed on the base; The second turntable is installed on the first turntable through a magnetic suction seat; the chuck is installed on the second turntable; the central axis of the first turntable, the central axis of the second turntable and the central axis of the chuck are all on the same line Above; the first displacement sensor and the second displacement sensor respectively pass through the base of the first height adjustment mechanism and the second height adjustment mechanism, and the first displacement sensor and the second displacement sensor are located on the same straight line. Specifically, when the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com