Large-flow detachable and washable thermostatic valve

A thermostatic valve and large flow technology, applied in the field of thermostatic valves, can solve the problems of small water flow channel aperture, large temperature change of mixed water, small water intake and output water volume, etc., to achieve small overall structure size, convenient operation and adjustment, and ingenious conception Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

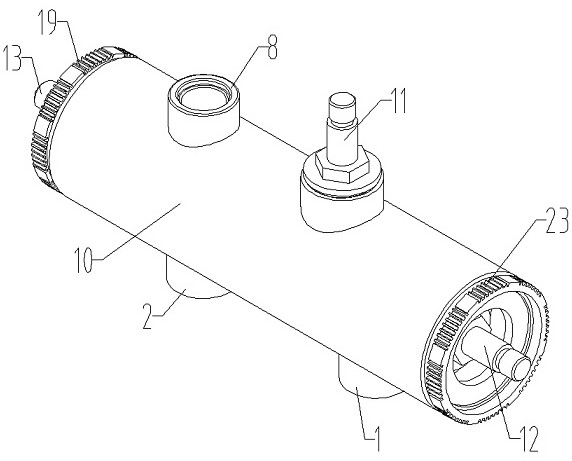

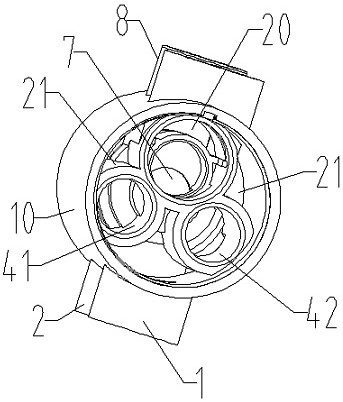

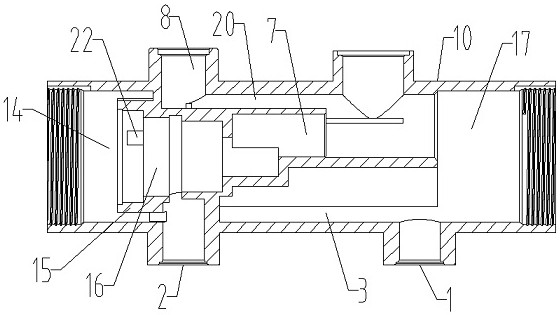

[0035] Example: see Figure 1-6 , a large flow detachable and washable thermostatic valve, including a thermostatic valve body 10, the inside of the thermostatic valve body 10 is provided with an installation cavity 14 and a water supply switch installation cavity 17, the installation cavity 14 and the water supply switch installation cavity 17 The openings are respectively arranged in opposite directions. The thermostatic valve body 10 is provided with a plurality of water delivery channels. The temperature adjustment switch 13 is detachably installed in the installation cavity 14. The water supply switch installation cavity 17 is detachably installed. There is a water supply switch 12, and the water supply switch 12 is used to control the on-off of the water supply channel.

[0036] A mounting seat 15 is integrally connected in the mounting chamber 14, the diameter of the outer surface of the mounting seat 15 is smaller than the diameter of the inner surface of the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com