Intelligent underwater bulldozer and cooling system thereof

A technology for cooling systems and bulldozers, which is applied in engine cooling, soil movers/shovels, and coolant flow control, etc., and can solve the problems of high heat dissipation requirements for hydraulic oil, achieve obvious heat dissipation effects, enhance cooling effects, Improve the effect of comprehensive heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

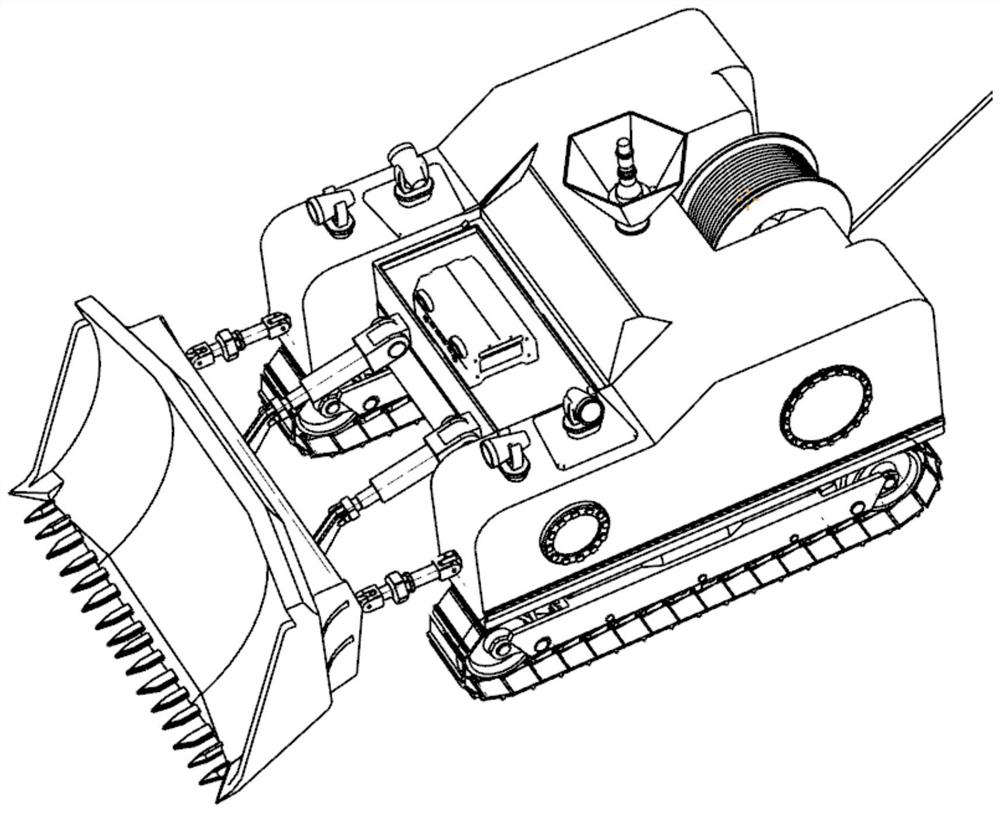

[0040] Such as figure 1 As shown, the intelligent underwater bulldozer has a closed structure as shown in the figure. The hydraulic drive system and power electronic equipment of the intelligent underwater bulldozer are completely isolated from the external water environment through sealing materials, and the internal air flow is poor, so it cannot be forced to dissipate heat through the cooling fan; and When the intelligent underwater bulldozer is working, the heat dissipation requirements of the hydraulic oil in the hydraulic drive system are different from those of the onboard power electronic equipment. Therefore, the present invention designs a cooling system for the intelligent underwater bulldozer.

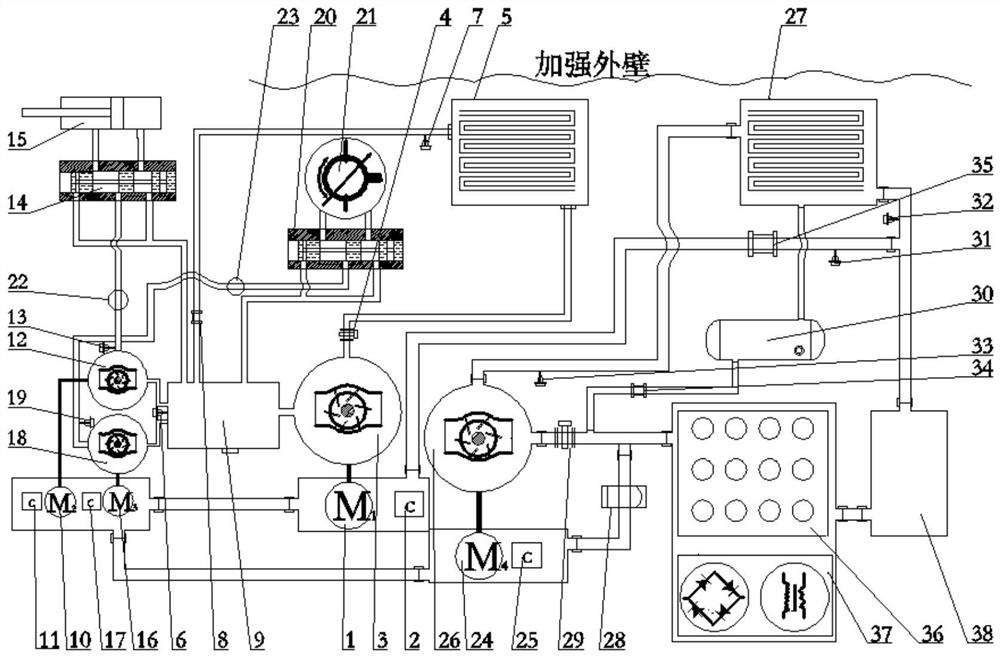

[0041] Such as figure 2 As shown, a cooling system of an intell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com