Cu-containing high-cleanliness non-oriented electrical steel plate and manufacturing method thereof

A oriented electrical steel sheet, high cleanliness technology, applied in the direction of manufacturing tools, circuits, electrical components, etc., can solve problems such as prolonging material manufacturing and delivery cycles, increasing manufacturing costs, production site technology, and troublesome quality management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A6-A17 and comparative example A1-A5

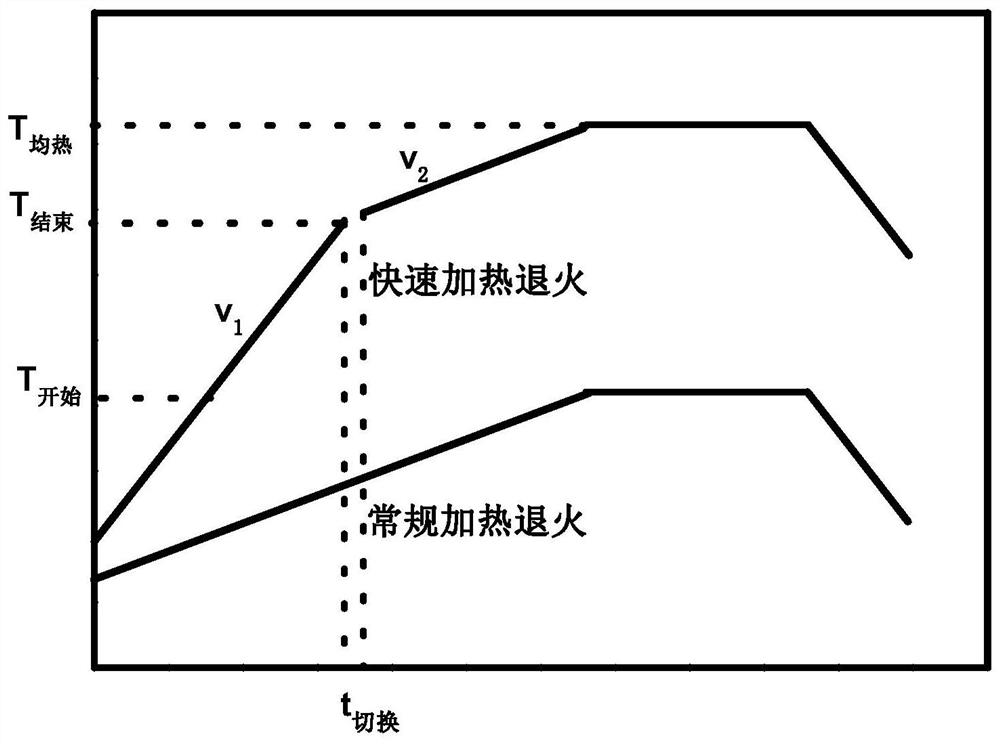

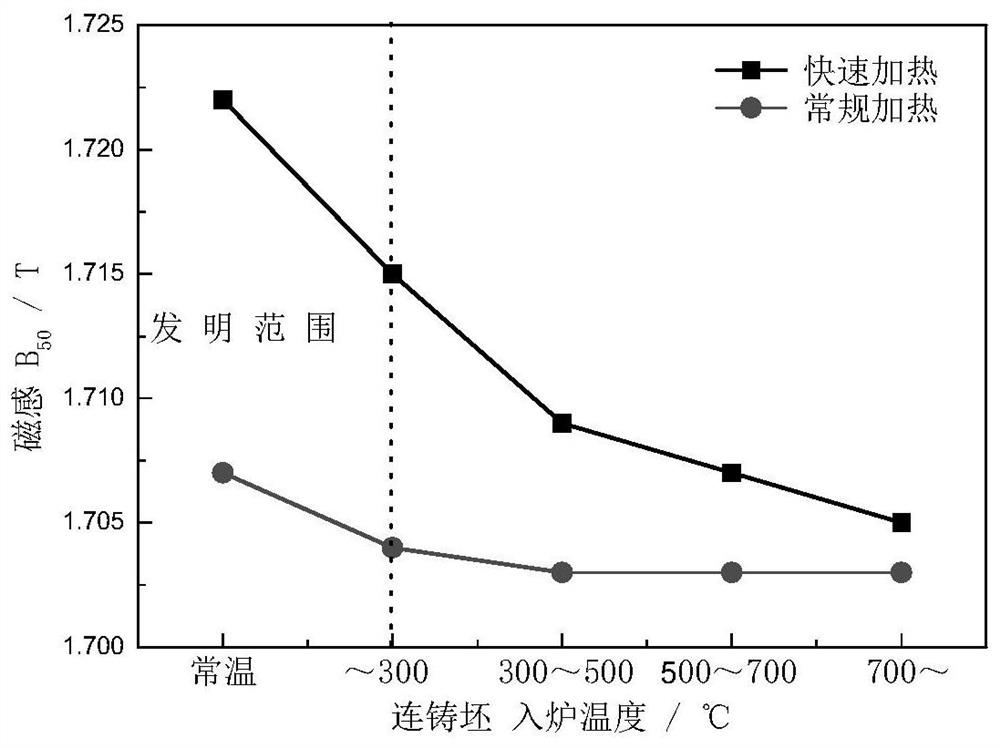

[0061] The Cu-containing high-cleanliness non-oriented electrical steel sheets of the above-mentioned examples A6-A17 and the conventional steel sheets of the comparative examples A1-A5 were prepared by the following steps:

[0062] (1) Smelting and casting are carried out according to the chemical composition shown in Table 1. Among them, molten iron and steel scrap can be matched according to the proportion. After smelting in the converter, after decarburization, deoxidation and alloying in RH refining, 120-250mm Thick, 800-1400mm wide continuous casting slab.

[0063] (2) Hot rolling: After the continuous casting slab undergoes rough rolling and finish rolling in sequence, a hot rolled steel coil is obtained, and the thickness of the steel coil is 1.5-2.8 mm.

[0064] (3) Normalization: The hot-rolled steel coil is subjected to normalization treatment. The normalized soaking temperature is 800-1000°C, and the soaking time is 1-180s.

[0065] (4) Cold rolling: use a contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com