Electric fossil filter material for sewage dephosphorization as well as preparation method and application thereof

A fossil and filter material technology, applied in the field of electro-fossil filter material for phosphorus removal in sewage and its preparation, can solve the problems of secondary pollution of aquatic organisms, difficult to find conditions, and difficult recovery of adsorbents, etc., and achieve high-efficiency phosphorus removal effect, preparation method Simple, the effect of increasing the phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

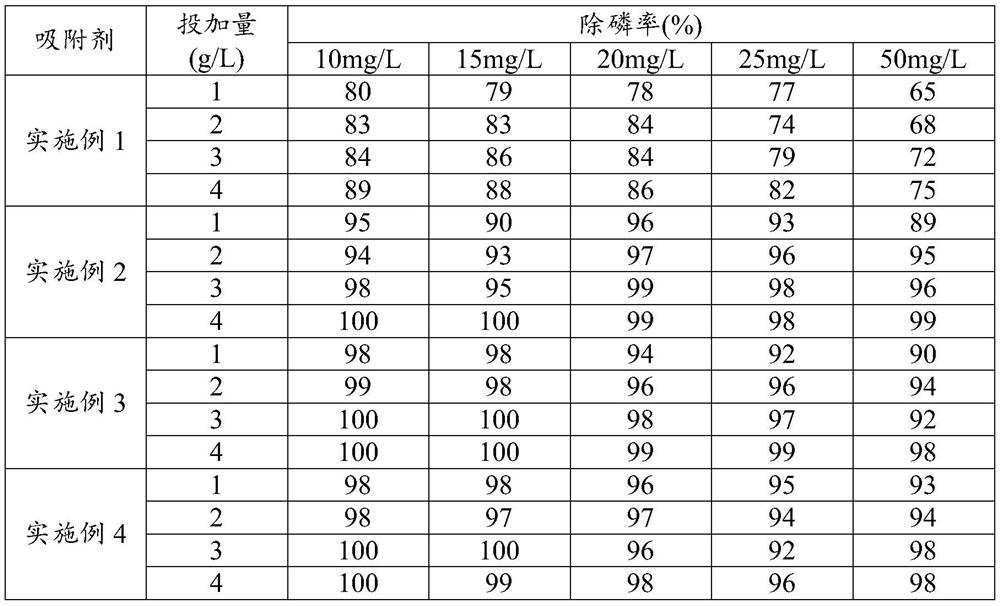

Examples

Embodiment 1

[0026] (1) Add 100g of powdered activated carbon into the potassium permanganate solution with a concentration of 1g / ml, completely immerse the activated carbon powder in the potassium permanganate solution, and carry out surface oxidation at 70°C for 3 hours; Wash with deionized water until the pH is neutral;

[0027] (2) Add 100g of urea to 200ml of deionized water, stir evenly to obtain an aqueous urea solution, add 20g of surface-oxidized activated carbon to 150g of aqueous urea, and react under the assistance of microwaves. The microwave power is 800W, and the reaction temperature is 80°C. The time is 2h; after the reaction is completed, filter, and dry the solid in a vacuum oven at 120°C for 24h;

[0028] (3) The dried product was calcined at a high temperature of 1200°C for 3 hours under a nitrogen protective atmosphere to obtain a modified activated carbon.

Embodiment 2

[0030] A method for preparing an electrochemical filter material for dephosphorization of sewage, comprising the following steps:

[0031] (1) Add 10g of iron powder into 50g of deionized water, ultrasonically disperse evenly to form a uniform mixed slurry, then add the mixed slurry into a ball mill for mechanical ball milling; in the process of mechanical ball milling, use large balls and small balls For the mixing method, the diameter of the large ball is 20mm, the diameter of the small ball is 10mm, the ball milling speed is 600rpm, the ball milling time is 8h, and the ball-to-material ratio is 20:1.

[0032] (2) Add 50 g of the modified activated carbon powder prepared in Example 1 to the ball-milled material, and heat and react at 80° C. for 5 h under microwave-assisted conditions; after the reaction, the resulting product passes through a 200-300 mesh sieve;

[0033] (3) Add 20ml of calcium titanate aqueous solution with a concentration of 0.5mol / L to the sieved product ...

Embodiment 3

[0036] A method for preparing an electrochemical filter material for dephosphorization of sewage, comprising the following steps:

[0037] (1) Add 10g of iron powder into 50g of deionized water, ultrasonically disperse evenly to form a uniform mixed slurry, then add the mixed slurry into a ball mill for mechanical ball milling; in the process of mechanical ball milling, use large balls and small balls For the mixing method, the diameter of the large ball is 20mm, the diameter of the small ball is 10mm, the ball milling speed is 700rpm, the ball milling time is 8h, and the ball-to-material ratio is 30:1.

[0038] (2) Add 50 g of the modified activated carbon powder prepared in Example 1 to the ball-milled material, and heat and react at 80° C. for 5 h under microwave-assisted conditions; after the reaction, the resulting product passes through a 200-300 mesh sieve;

[0039] (3) To the product after sieving, 20ml of calcium titanate aqueous solution with a concentration of 1.0mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com