CHA molecular sieve, synthesis method thereof, catalyst synthesized by using CHA molecular sieve and application

A technology of SCR catalyst and molecular sieve, applied in molecular sieve catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems of high price, low utilization rate, large reduction pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

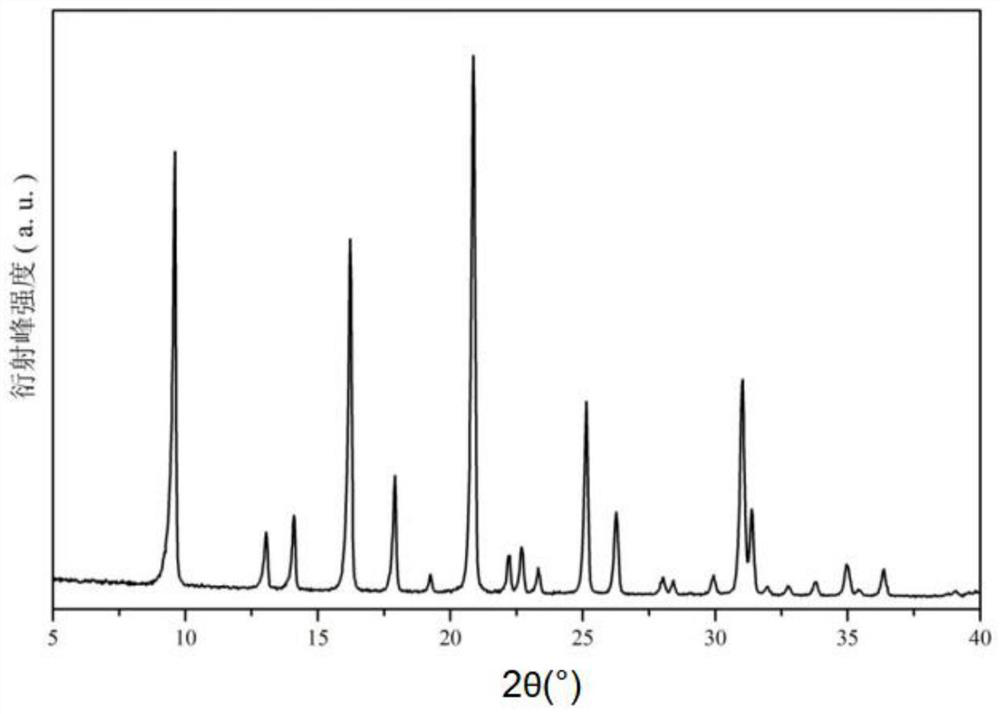

[0047] In a specific embodiment of the present invention, the present invention provides a kind of CHA molecular sieve and its synthetic method, it is characterized in that: the quaternary ammonium compound containing tetrahydronaphthalene or decahydronaphthalene group and N,N,N- The composite organic template of dimethyl ethyl cyclohexyl quaternary ammonium compound synthesizes CHA type zeolite molecular sieve, the molar ratio range of silica to alumina of the product ranges from 5 to 75, and the total specific surface area measured by BET method is 400 to 750m 2 / g, the total pore volume is 0.25~0.45ml / g, the micropore pore volume is 0.12~0.25ml / g; the molecular sieve average grain diameter≤500nm, X-ray crystal diffraction (-210) half-value width of crystal plane ( The range of FWHM) is 0.1-0.15°, and the grain diameter in the (-210) direction of the crystal plane is calculated by the Debye-Scherrer formula to be 80-160nm;

[0048] The pore structure data of molecular sieves...

Embodiment 1

[0097] A kind of preparation method of CHA type SSZ-13 molecular sieve and SCR catalyst:

[0098] 1) Add 593.72g of silica sol (Na2O: 0.24wt%, SiO2: 30.36wt%) as a silicon source to 196.99g of deionized water and mix evenly under ultrasonic stirring conditions, and then add 11.50g of pseudo-thin water as an aluminum source Alite (dry basis 77.0wt%) molecular sieves, 58.69g NaOH flake base were fully stirred to form a silica-alumina gel, and then 241.42g N,N-dimethyl-N'-ethyl-(decalin-1 - base) ammonium hydroxide (concentration 20wt%, represented by OSDA1), 27.73g N, N, N-dimethyl ethyl cyclohexyl ammonium hydroxide (concentration 25wt%, represented by OSDA2) and stir well; then add 8.85 g NaCl (99wt%) as the metal salt M is added to the solution and mixed fully; finally add 5% HCl solution to adjust the nOH in the system - / nSiO 2 Ratio, making the mixed slurry component molar ratio nNa 2 O:nSiO 2 :n A1 2 o 3 :nOH-:nOSDA1:nOSDA2:nNaCl:nH 2 O=0.25:1.0:0.0286:0.58:0.0667:...

Embodiment 2

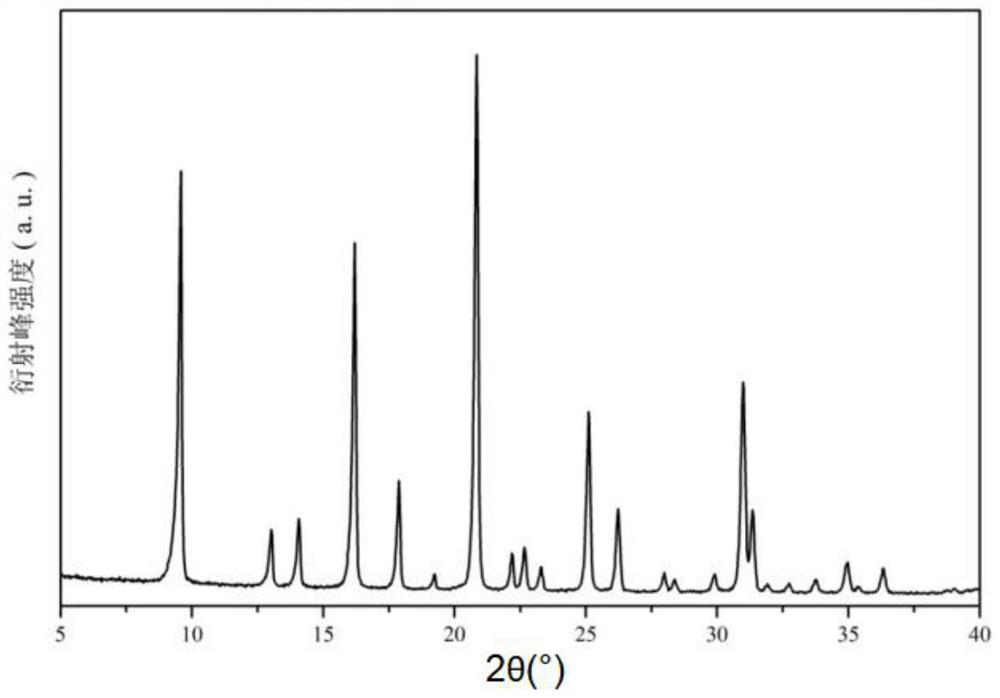

[0105] The process method of synthesizing CHA type SSZ-13 molecular sieve is similar to embodiment 1, and difference is the molar ratio of mixed sol in step 1), two kinds of organic templating agent types, silicon source, the kind of aluminum source, seed crystal addition amount , add acid species, metal salt M species, step 2) crystallization temperature and crystallization time etc., step 4) get H type SSZ-13 molecular sieve 50.0g, adopt different soluble metal salt species, concentration, solution volume and metal Loading capacity, and step 5) get 40.0g copper-modified CHA type SSZ-13 molecular sieve, with 24.88 silica sol (SiO 2 content: 30.0wt%) and 121.25g deionized water were evenly mixed to make a catalyst slurry with a solid content of 25.5wt%, which was coated on the cordierite structured material by dipping method. Specific parameters in this embodiment are shown in Table 1, Table 2, Table 3 and Table 4. Wherein, the XRD diffraction pattern of the CHA type SSZ-13 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com