Preparation method of skin-touch coating on surface of wood board

A wood-based board and skin-feeling technology, which is applied to the preparation of skin-feeling coatings on the surface of wooden boards, using UV-inkjet 3D printing technology to prepare skin-feeling coatings on the surface of woody boards, which can solve the problem of single skin performance and low production efficiency , poor repeatability and other problems, to achieve the effect of simple process, high production efficiency and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

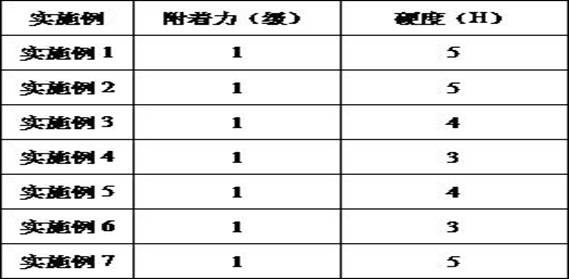

Examples

Embodiment 1

[0023] A method for preparing a skin-feeling coating on the surface of a wooden board described in this embodiment comprises the following steps:

[0024] Step 1: Use a microscope to take pictures to collect the texture structure of the cotton fiber surface, and adjust the clarity and brightness of the texture structure;

[0025] Step 2: Import the cotton fiber surface texture described in step 1 into the UV-inkjet 3D printer, set the resolution of the printed skin texture to 1200dpi, the printing speed to 0.3m / s, and the UV wavelength to 380nm;

[0026] Step 3: Sanding the surface of the solid wood board to make the surface roughness 1.0mm;

[0027] Step 4: Using the printing parameters in Step 2, print acrylic resin layer by layer on the surface of the solid wood panel prepared in Step 3 to prepare a skin-feeling coating on the surface of the solid wood panel.

Embodiment 2

[0029] A method for preparing a skin-feeling coating on the surface of a wooden board described in this embodiment comprises the following steps:

[0030] Step 1: Use a scanning electron microscope to take pictures to collect the texture structure on the surface of the matte polyurethane coating, and adjust the clarity and brightness of the texture structure;

[0031] Step 2: import the surface texture of the self-dulling polyurethane coating described in step 1 into the UV-inkjet 3D printer, set the resolution of the printed skin texture to 2400dpi, the printing speed to 0.5m / s, and the UV wavelength to 360nm;

[0032] Step 3: Sanding the surface of the blockboard to make the surface roughness 0.3mm;

[0033] Step 4: Using the printing parameters in step 2, print acrylic resin layer by layer on the surface of the blockboard prepared in step 3 to prepare a skin-feeling coating on the surface of the blockboard.

Embodiment 3

[0035] A method for preparing a skin-feeling coating on the surface of a wooden board described in this embodiment comprises the following steps:

[0036] Step 1: Use a scanning electron microscope to take pictures to collect the texture structure of the cotton fiber surface, and adjust the clarity and brightness of the texture structure;

[0037] Step 2: import the cotton fiber surface texture described in step 1 into the UV-inkjet 3D printer, set the resolution of the printed skin texture to 600dpi, the printing speed to 0.05m / s, and the UV wavelength to 400nm;

[0038] Step 3: Sanding the surface of the plywood to make the surface roughness 3.0mm;

[0039] Step 4: Using the printing parameters in Step 2, print epoxy resin layer by layer on the surface of the plywood prepared in Step 3 to prepare a skin-feeling coating on the surface of the plywood.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com