Rolling device for realizing various super-hydrophobic surface microstructure morphologies and application method of rolling device

A technology of super-hydrophobic surface and rolling device, applied in the field of rolling device, can solve the problems such as the inability to prepare surfaces with different microstructures in a large area, and the preparation process of microstructured surfaces is complicated, so as to improve the preparation speed, reduce labor consumption, Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

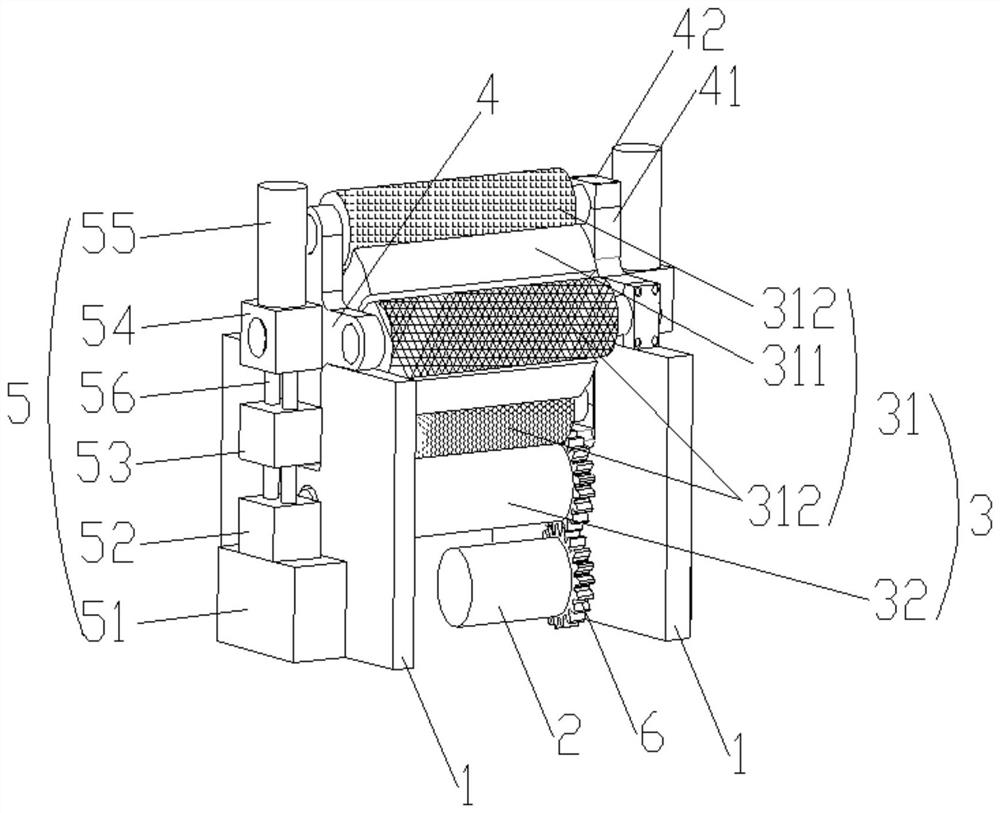

[0027] A rolling device that realizes a variety of superhydrophobic surface microstructure topography, the schematic diagram of which is shown in figure 1 As shown, it includes a base 1 and a driving mechanism 2 and a pressure roller part 3 arranged in the base 1 in order from bottom to top. connect;

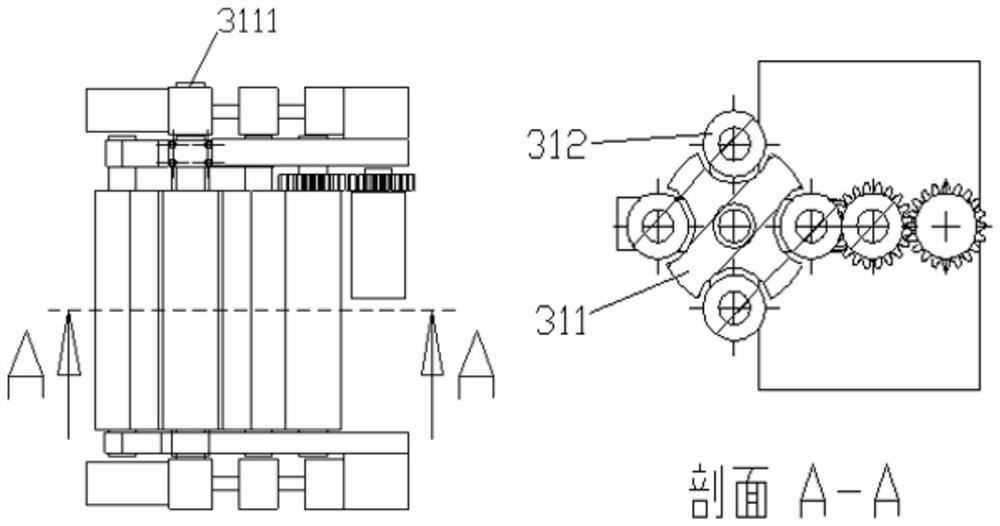

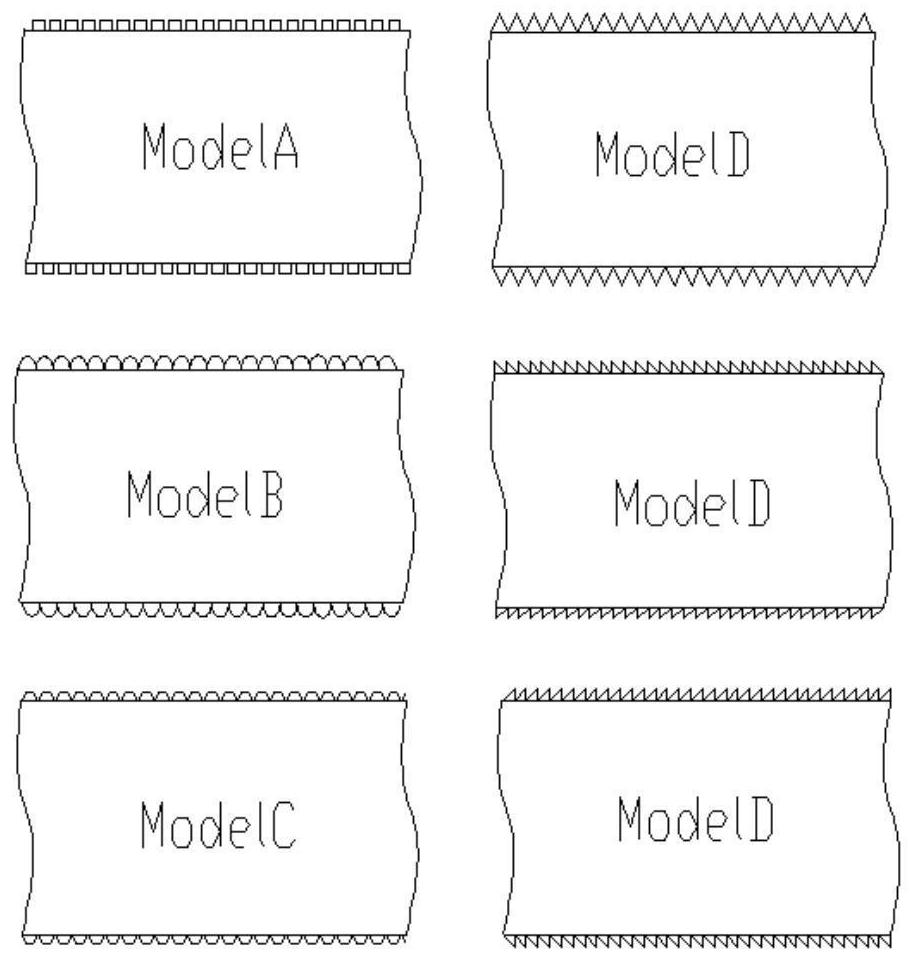

[0028] The pressure roller part 3 comprises an upper pressure roller group 31 and a lower pressure roller 32, and the upper pressure roller group 31 comprises an upper pressure roller frame 311 and four upper pressure rollers 312 with different surface topography installed around the upper pressure roller frame 311. An upper pressure roller 312 is detachably connected with the upper pressure roller frame 311, and the upper pressure roller frame 312 is movably installed on the base 1, and the two ends of the lower pressure roller 32 are installed on the base 1; one of the upper pressure rollers 312 is connected with the lower pressure roller The rollers 32 are parallel and leave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com