Optimized robot calibration method and device

A robot and a technology to be calibrated, applied in the field of robot calibration, can solve problems such as high requirements for testers, low efficiency, and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

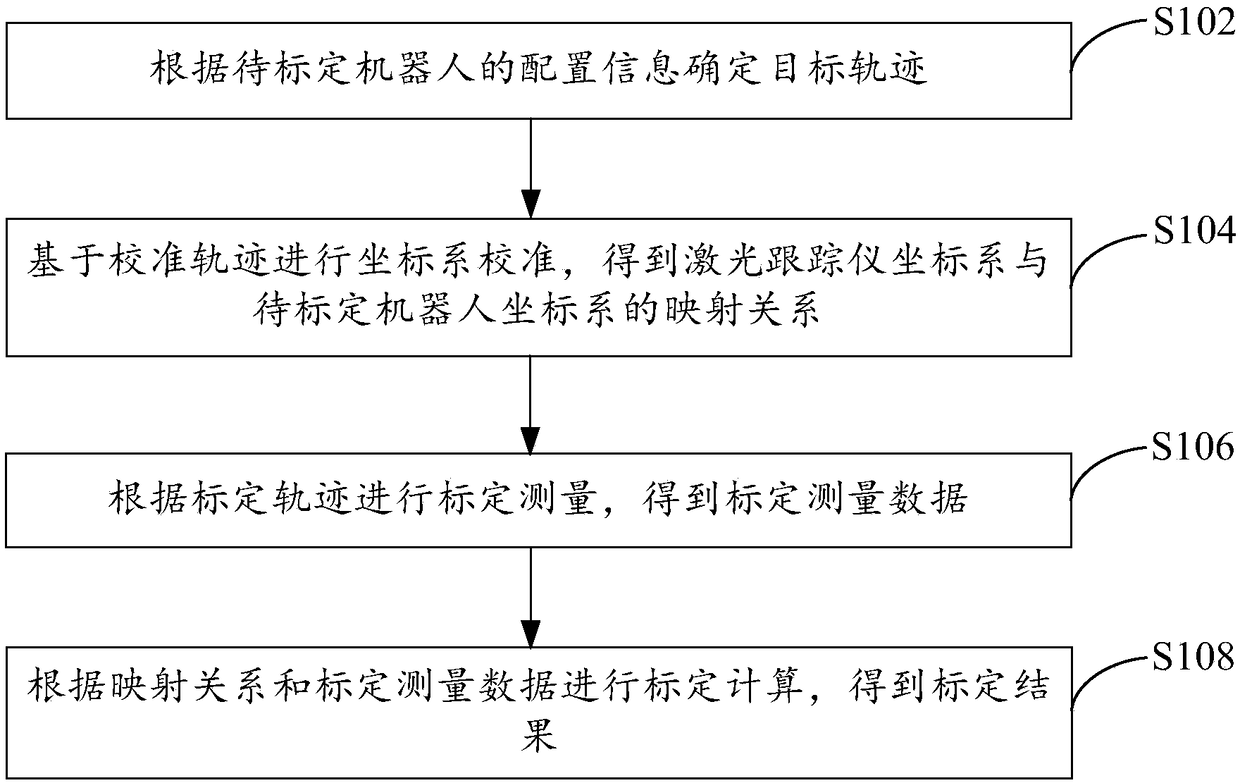

[0067] An optimized robot calibration method, applied to the test system software, the test system software is set on the terminal equipment, refer to figure 1 , the method includes:

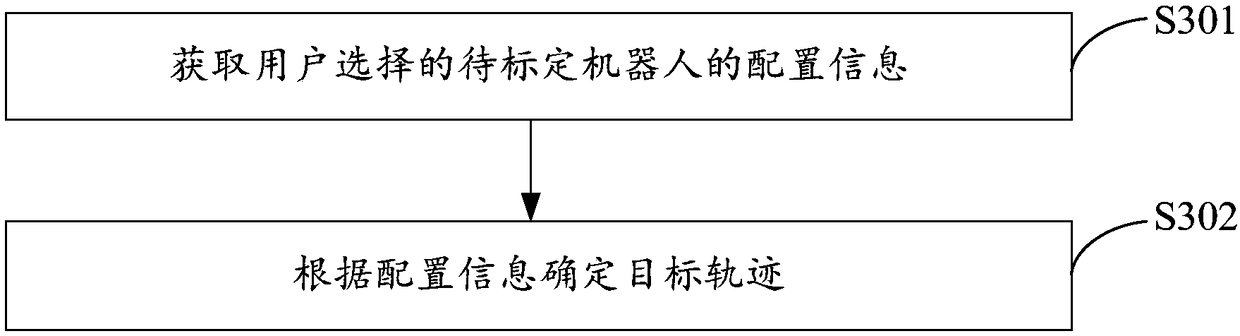

[0068] S102. Determine the target trajectory according to the configuration information of the robot to be calibrated, wherein the target trajectory includes: a calibration trajectory, a calibration trajectory;

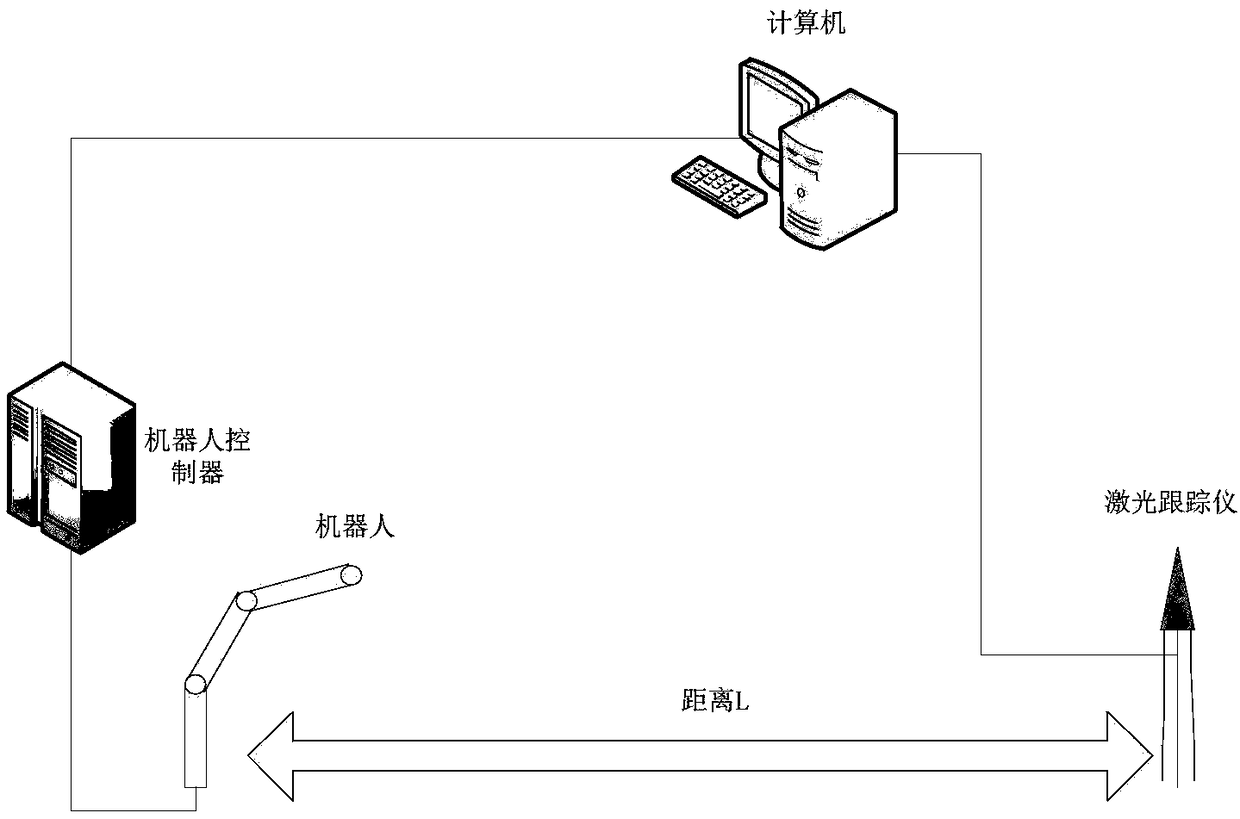

[0069] In the embodiment of the present invention, the execution subject of the optimized robot calibration method is the test system software, and the test system software is installed on the terminal device. Specifically, the terminal device may be a computer.

[0070] The test system software in the present invention can determine the target trajectory according to the configuration information of the robot to be calibrated without user-defined trajectory. The specific content will be described below and will not be repeated here.

[0071] S104. Calibrate the coordinate system base...

Embodiment 2

[0141] An optimized robot calibration device, the device is set on the terminal equipment, refer to Figure 7 , the device consists of:

[0142] Determining module 11, is used for determining target track according to the configuration information of robot to be calibrated, and wherein, target track comprises: calibration track, calibration track;

[0143] The coordinate system calibration module 12 is used to calibrate the coordinate system based on the calibration trajectory to obtain the mapping relationship between the laser tracker coordinate system and the robot coordinate system to be calibrated;

[0144] The calibration measurement module 13 is used to perform calibration measurement according to the calibration trajectory to obtain calibration measurement data, wherein the calibration measurement data includes: the end coordinates of the robot to be calibrated, the attitude angle of the robot to be calibrated, and the target ball coordinates measured by the laser trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com