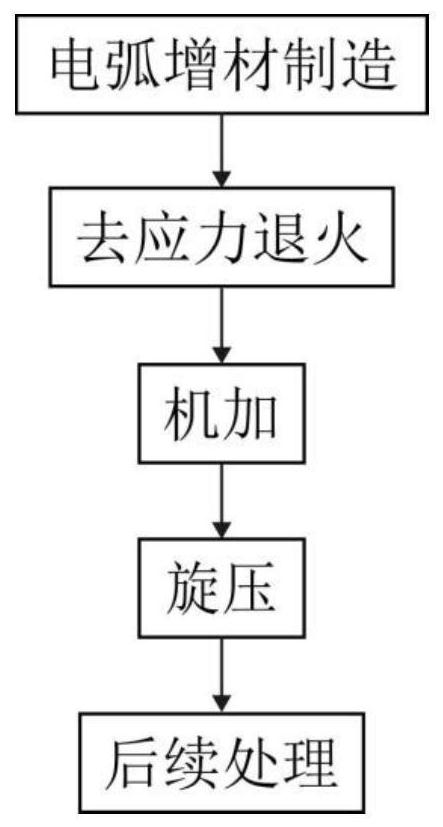

Manufacturing method of large-caliber thin-wall seamless titanium alloy cylinder

A technology of seamless titanium alloy and manufacturing method, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of reducing process flow, reducing deformation resistance, and difficult-to-deform titanium alloy, so as to reduce process flow and reduce deformation Resistance, the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

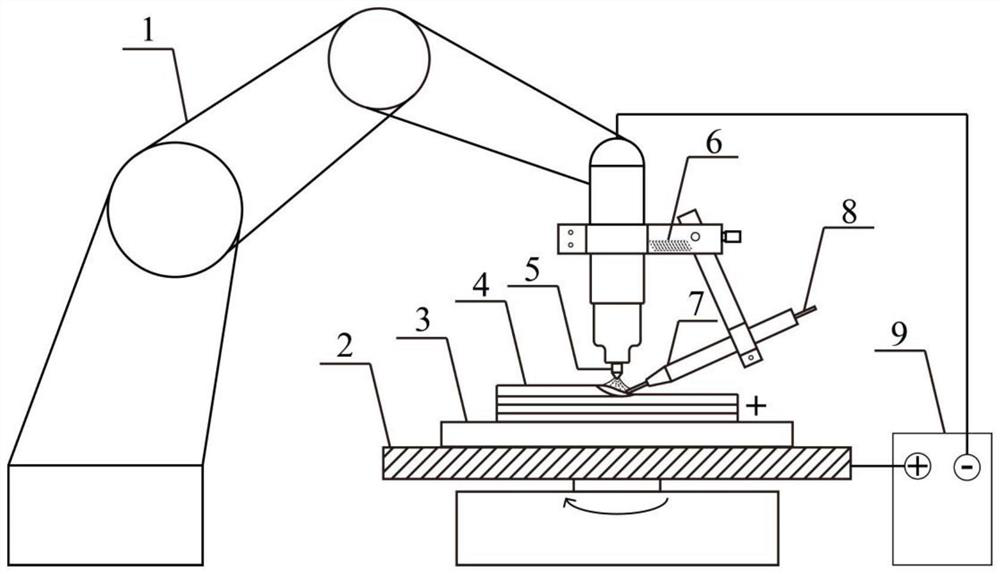

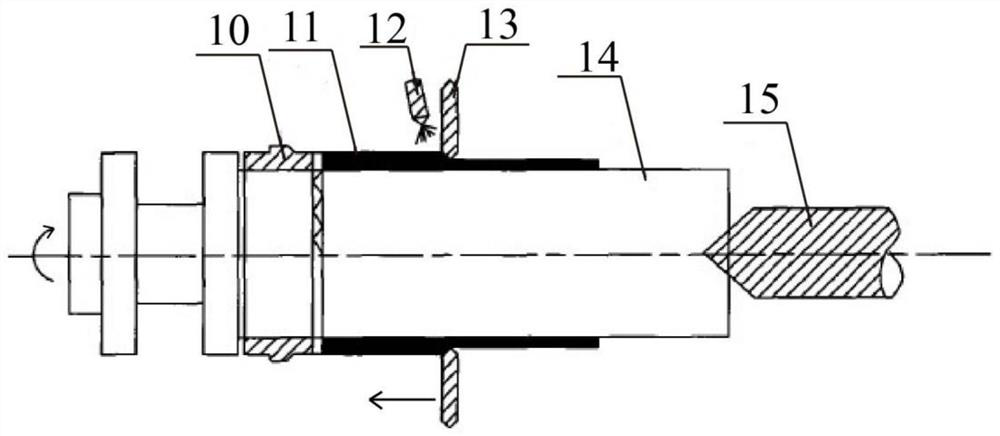

[0040] This embodiment includes the following steps:

[0041] Step 1. Additive manufacturing: adopt the arc additive manufacturing method to prepare a titanium alloy tube blank on the substrate; the specific process of the arc additive manufacturing method is: use a TC4 titanium alloy plate with a thickness of 15 mm as the substrate, and use a diameter of 1.2 mm TC4 titanium alloy wire is used as the welding wire. The welding wire is always in front of the welding direction. The wire feeding angle adjustment device adopts a spring with a wire diameter of 1mm. The wire feeding angle is 15°±2°, and the distance between the welding tungsten electrode and the welding bead is 3-5mm, the manufacturing process is carried out under the protective atmosphere of argon gas, the welding speed is 5mm / s, the wire feeding speed is 30mm / s, the welding current used in arc additive manufacturing is 100A, and the time for controlling the positioner to rotate one circle and The lifting interval o...

Embodiment 2

[0047] This embodiment includes the following steps:

[0048] Step 1. Additive manufacturing: the arc additive manufacturing method is used to prepare a titanium alloy tube blank on the substrate; the specific process of the arc additive manufacturing method is as follows: a TC4 titanium alloy plate with a thickness of 15mm is used as the substrate, and a diameter of 1.5 mm is used. mm TC4 titanium alloy wire is used as the welding wire. The welding wire is always in front of the welding direction. The wire feeding angle adjustment device adopts a spring with a wire diameter of 1mm. The wire feeding angle is 15°±2°, and the distance between the welding tungsten electrode and the welding bead is 3-5mm, the manufacturing process is carried out under the protective atmosphere of argon gas, the welding speed is 4mm / s, the wire feeding speed is 20mm / s, the welding current used in arc additive manufacturing is 120A, and the time for controlling the positioner to rotate one circle and...

Embodiment 3

[0054] This embodiment includes the following steps:

[0055] Step 1. Additive manufacturing: adopt the arc additive manufacturing method to prepare a titanium alloy tube blank on the substrate; the specific process of the arc additive manufacturing method is: use a TC4 titanium alloy plate with a thickness of 20mm as the substrate, and use a TC4 titanium alloy plate with a diameter of 1.5 mm TC4 titanium alloy wire is used as the welding wire. The welding wire is always in front of the welding direction. The wire feeding angle adjustment device adopts a spring with a wire diameter of 1mm. The wire feeding angle is 15°±2°, and the distance between the welding tungsten electrode and the welding bead is 3-5mm, the manufacturing process is carried out under the protective atmosphere of argon gas, the welding speed is 4mm / s, the wire feeding speed is 30mm / s, the welding current used in arc additive manufacturing is 140A, and the time for controlling the positioner to rotate one cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com