A method of preparing copper-based superlyophobic self-cleaning surface by ultrafast laser

An ultra-fast laser and super-lyophobic technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., to achieve the effect of increasing complexity, low price, and improving super-lyophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, a kind of method utilizing ultrafast laser to prepare copper-based super-lyophobic self-cleaning surface, comprises the following steps:

[0029] 1) Using metal copper as the base material, use 200#, 400#, 800#, 1000# and 1500# metallographic sandpaper to polish the surface of the copper-based sample step by step, and perform polishing treatment, and finally place them in absolute ethanol Ultrasonic cleaning with deionized water for 10 minutes, and drying in soft air flow after taking out;

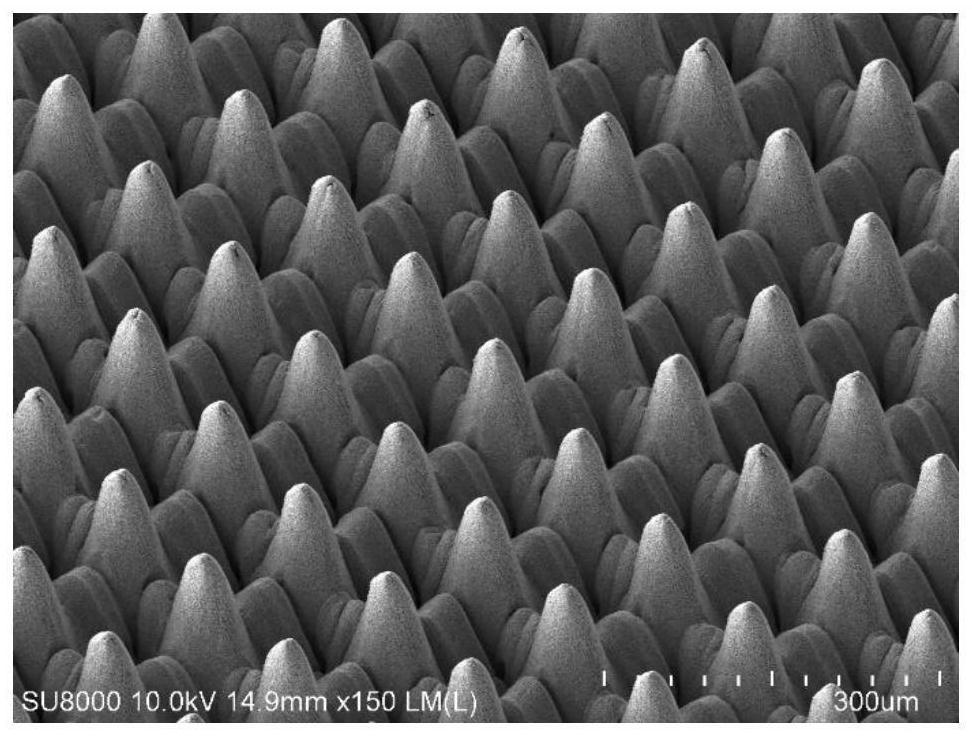

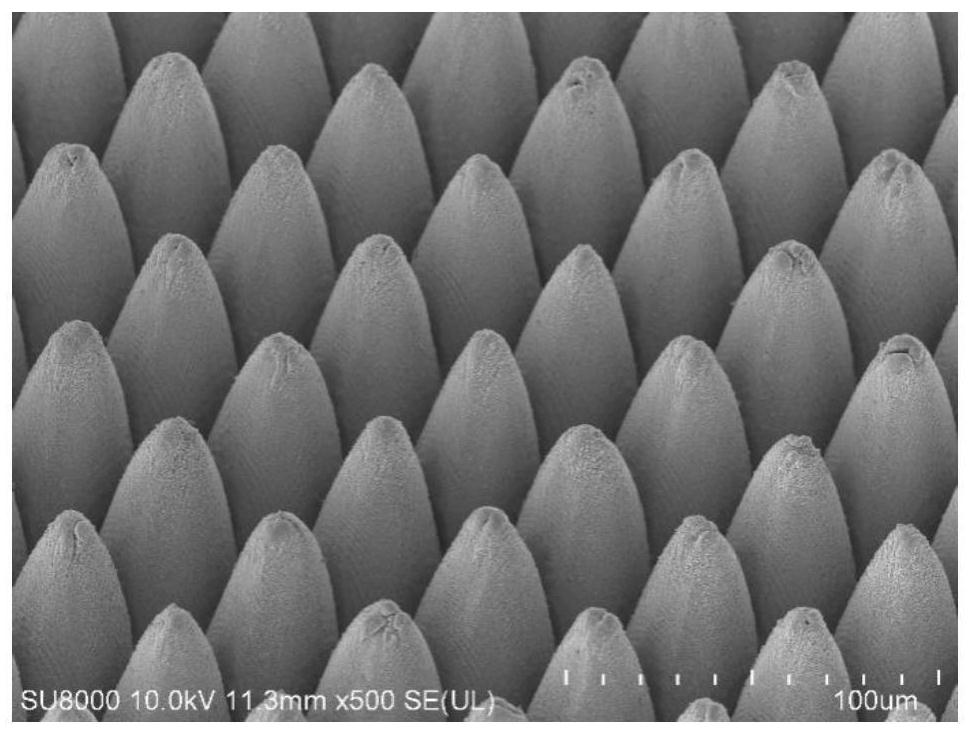

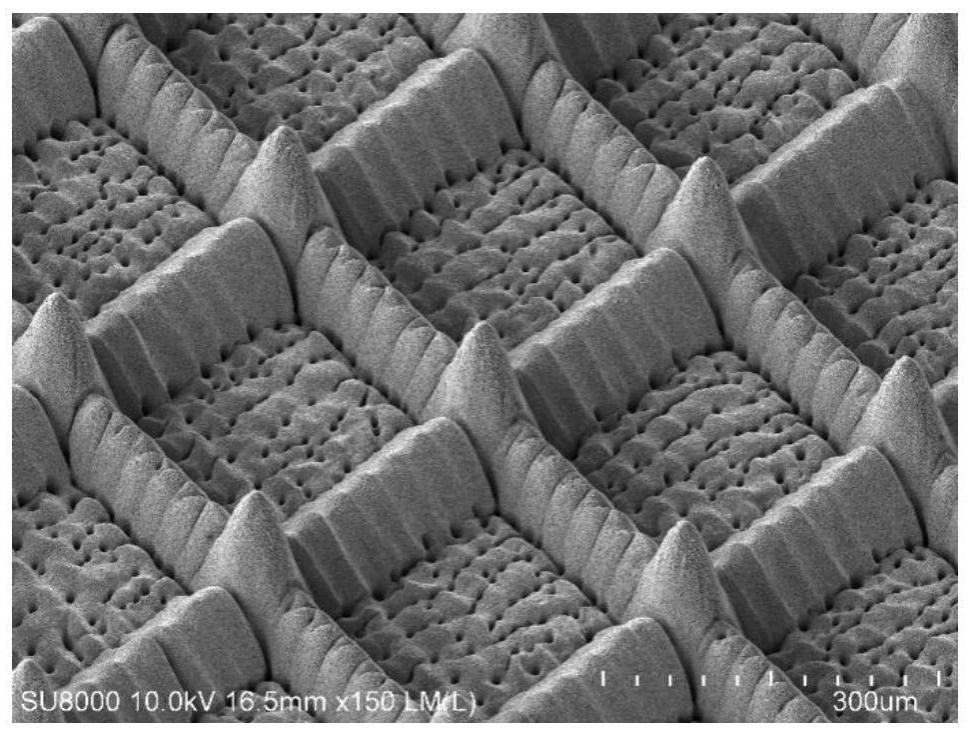

[0030] 2) Process the copper polished sample obtained in step 1) with an ultrafast laser, the laser wavelength is 1030nm, the pulse width is 240fs, and the diameter of the laser beam waist spot is 35 μm; adjust the laser repetition frequency, laser energy, scanning speed and number of repetitions, Obtain the process parameters of laser preparation of microcones, secondary grids and nanoparticles: repetition frequency 200kHz, laser energy 6W, scanning speed 100mm / s, rep...

Embodiment 2

[0035] Embodiment 2, a kind of method utilizing ultrafast laser to prepare copper-based super-lyophobic self-cleaning surface, comprises the following steps:

[0036] 1) Using metal copper as the base material, use 200#, 400#, 800#, 1000# and 1500# metallographic sandpaper to polish the surface of the copper-based sample step by step, and perform polishing treatment, and finally place them in absolute ethanol Ultrasonic cleaning with deionized water for 10 minutes, and drying in soft air flow after taking out;

[0037] 2) Process the copper polished sample obtained in step 1) with an ultrafast laser, the laser wavelength is 1030nm, the pulse width is 240fs, and the diameter of the laser beam waist spot is 35 μm; adjust the laser repetition frequency, laser energy, scanning speed and number of repetitions, Obtain the process parameters of laser preparation of microcones, secondary grids and nanoparticles: repetition frequency 200kHz, laser energy 6W, scanning speed 100mm / s, rep...

Embodiment 3

[0042] Embodiment 3, a kind of method utilizing ultrafast laser to prepare copper-based super-lyophobic self-cleaning surface, comprises the following steps:

[0043] 1) Using metal copper as the base material, use 200#, 400#, 800#, 1000# and 1500# metallographic sandpaper to polish the surface of the copper-based sample step by step, and perform polishing treatment, and finally place them in absolute ethanol Ultrasonic cleaning with deionized water for 10 minutes, and drying in soft air flow after taking out;

[0044] 2) Process the copper polished sample obtained in step 1) with an ultrafast laser, the laser wavelength is 1030nm, the pulse width is 240fs, and the diameter of the laser beam waist spot is 35 μm; adjust the laser repetition frequency, laser energy, scanning speed and number of repetitions, Obtain the process parameters of laser preparation of microcones, secondary grids and nanoparticles: repetition frequency 200kHz, laser energy 6W, scanning speed 100mm / s, rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com