Aluminum alloy semi-solid slurry preparation device, die-casting equipment and die-casting process

A technology for semi-solid slurry and preparation device, which is applied in the field of aluminum alloy casting, and can solve the problems of untimely feeding and shrinking between microscopic dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

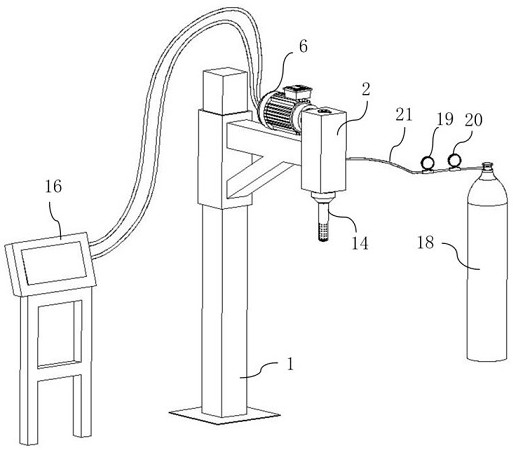

[0030] An aluminum alloy semi-solid slurry preparation device is disclosed in Example 1, such as Figure 1-2 As shown in , including a support 1, a nitrogen supply device and a stirring device, the support 1 is used to install the stirring device. The stirring equipment includes a box body 2 , a sealing baffle 3 , a motor 6 , a driven gear 7 , a motor gear 8 , a connecting rod 9 , a blade disc 10 , a rotor 14 , and a control panel 16 . A sealing baffle 3 is arranged in the box 2, and the sealing baffle 3 divides the box 2 into an upper box 4 and a lower box 5. Connecting rod 9 is set in described upper box body 4, as figure 2 As shown in , the upper part of the connecting rod 9 is rotatably fixed on the top surface of the box body 2 (for example, through a bearing), and the lower part of the connecting rod 9 is rotatably fixed on the sealing baffle 3 . The connecting rod 9 is fixed at the center of the driven gear 7, the output shaft of the motor 6 is fixed at the center of...

Embodiment 2

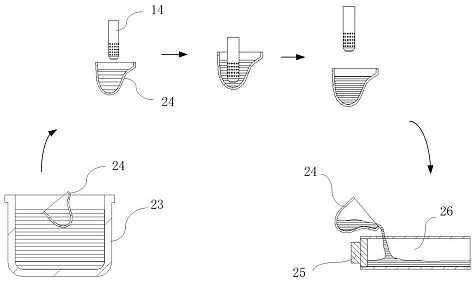

[0036] Embodiment 2 provides a die-casting equipment for aluminum alloy castings, including a holding furnace 23, a soup feeder, a die-casting machine, a casting mold, and an aluminum alloy semi-solid slurry preparation device as described in Embodiment 1. Wherein the die casting machine includes a punch 25 and a pressure chamber 26 . The soup dispenser includes a spoon 24, which is used to transport the molten aluminum from the holding furnace 23 to the pressure chamber 26 of the die-casting machine.

[0037] A die-casting process for aluminum alloy castings of a die-casting equipment for aluminum alloy castings described in Example 2 includes the following steps, such as image 3 As shown in: Set and control the temperature of the aluminum alloy liquid in the holding furnace to 625±5°C, take the aluminum alloy liquid from the holding furnace with a spoon, and transport it to the rotor of the aluminum alloy semi-solid slurry preparation device Below: the rotor physically sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com