Integrated reflux system with built-in heat recovery device and air purification device

A technology of air purification device and heat recovery device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] (Temperature reduction effect of polluted air by condenser)

[0094] ①Measurement method of temperature reduction effect

[0095] like image 3 As shown, the condenser is made in the radiator type, and the temperature of the polluted air discharged from the reflow furnace and passed through the heat exchanger is measured at the front end of the condenser and the rear end of the condenser, respectively, and the temperature reduction effect is compared and studied.

[0096] At this time, the return flow reaches the time point of normal operation, that is, the temperature is measured every 1 hour after starting 2 hours, based on the suction air volume of the blower is 3m 3 / min.

[0097] ②Measurement results of temperature reduction effect of polluted air

[0098] After the reflux reaches normal operating conditions, the temperature of the polluted air in the front end of the condenser is shown to be about 79.3°C at the time point of 1 hour, and the temperature of the ...

Embodiment 2

[0103] (Based on the removal effect of the effluent of the roll-to-roll dust collector)

[0104] ①Measuring method of removal effect of effluent

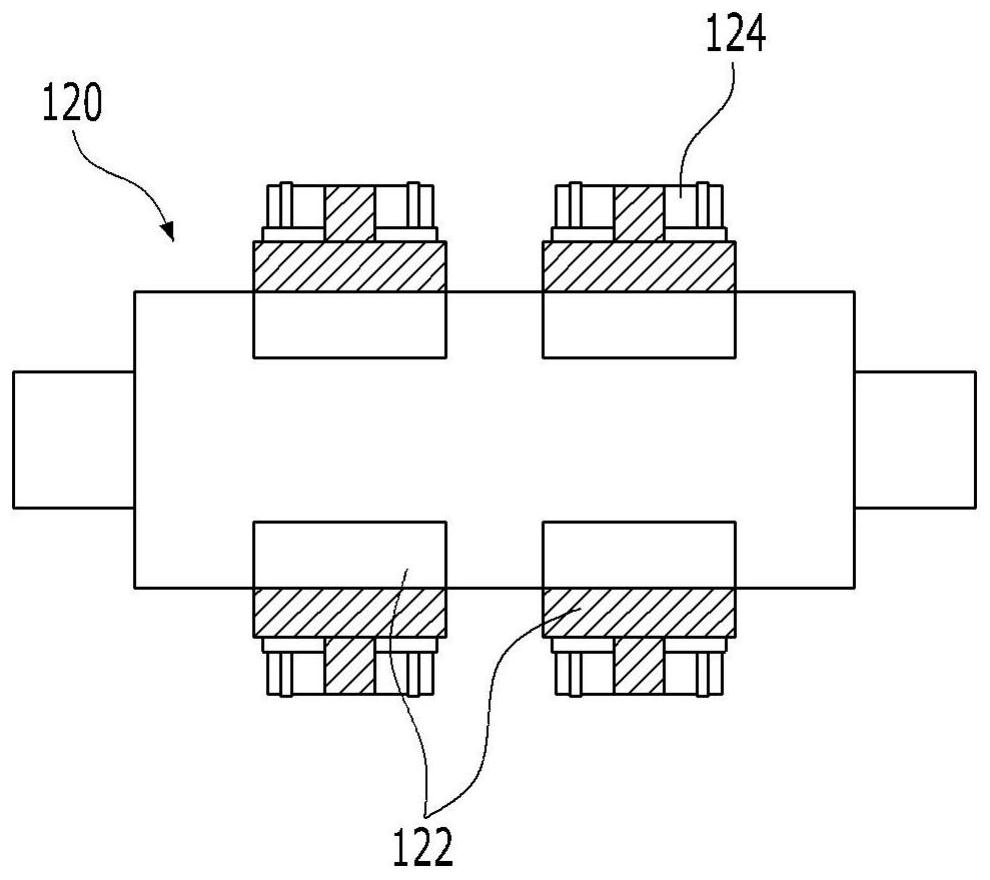

[0105] use Figure 4 In the roll-to-roll dust collector shown in the figure, the removal effect of the effluent contained in the polluted air generated during reflow soldering was measured with the naked eye.

[0106] The PCB board coated with solder paste is put into reflow, and the polluted air generated when the solder paste is melted in the furnace at about 250°C is the same as , and the effluent is condensed by a condenser, and the dust is collected in roll-to-roll The trapping occurs on the filter side of the device.

[0107] The measurement experiment of the removal effect of the effluent is determined by the number of PCB boards loaded, divided into 5 times, and the degree of capture on one side is measured respectively.

[0108] At this time, the suction air volume is set to 3m under the same conditions as 3 / min, and...

Embodiment 3

[0116] (reduction effect of power consumption of reflow)

[0117] ①Measuring method of power consumption by adopting heat recovery device

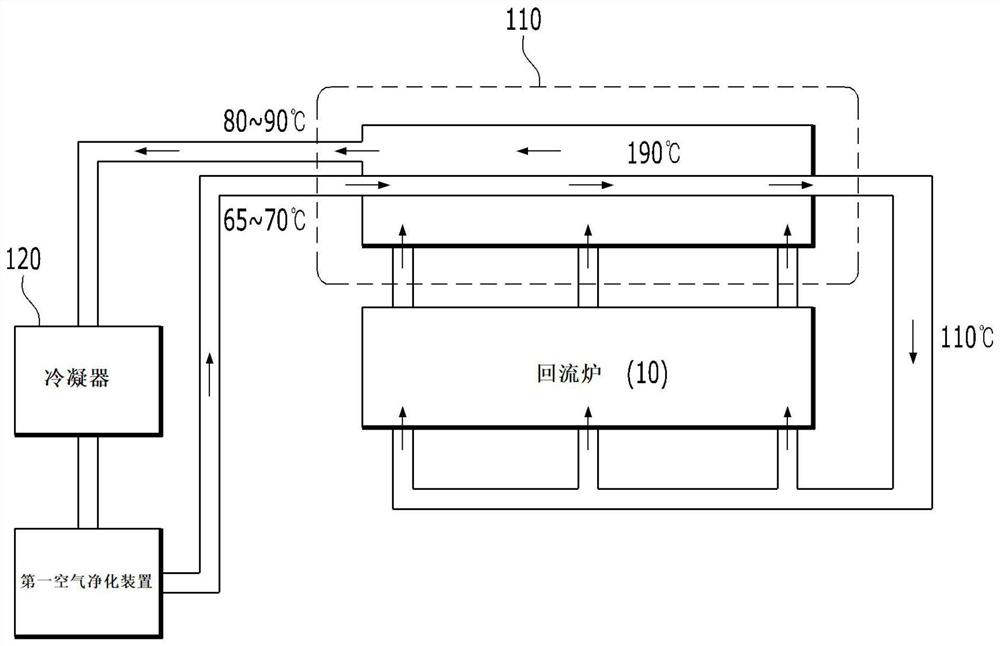

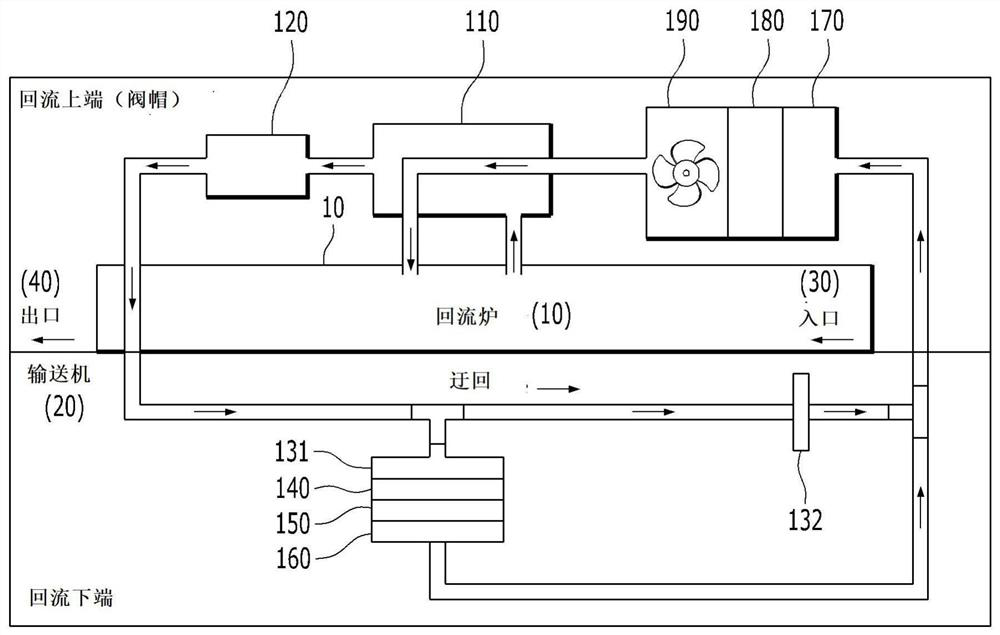

[0118] like figure 1 As shown in the schematic diagram of the heat recovery device, the air purified in real time based on the air purification device is heated up to about 110°C through the heat exchanger by using the polluted air with a high temperature of about 190°C discharged from the reflow furnace, and then re-introduced into the inside of the reflow furnace , so as to reduce the power consumption of reflux.

[0119] At this time, the suction air volume is set to 3m under the same conditions as in an industrial site 3 / min, use the integrated wattmeter to compare and measure the power consumption of the reflux before and after the use of the heat recovery device within 4 hours.

[0120] ②Measurement results of power consumption of reflow

[0121] refer to Figure 9 , before adopting the heat recovery device, the power consumpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com