Elastomer epoxy resin-based all-solid-state electrolyte as well as preparation method and application thereof

A technology of bulk epoxy resin and epoxy resin, which is applied in the field of elastomeric epoxy resin-based all-solid-state electrolyte and its preparation, can solve the problems of increased battery interface resistance, unfavorable cation transmission, and decreased cycle performance, so as to improve energy efficiency. Density, increase ionic conductivity, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

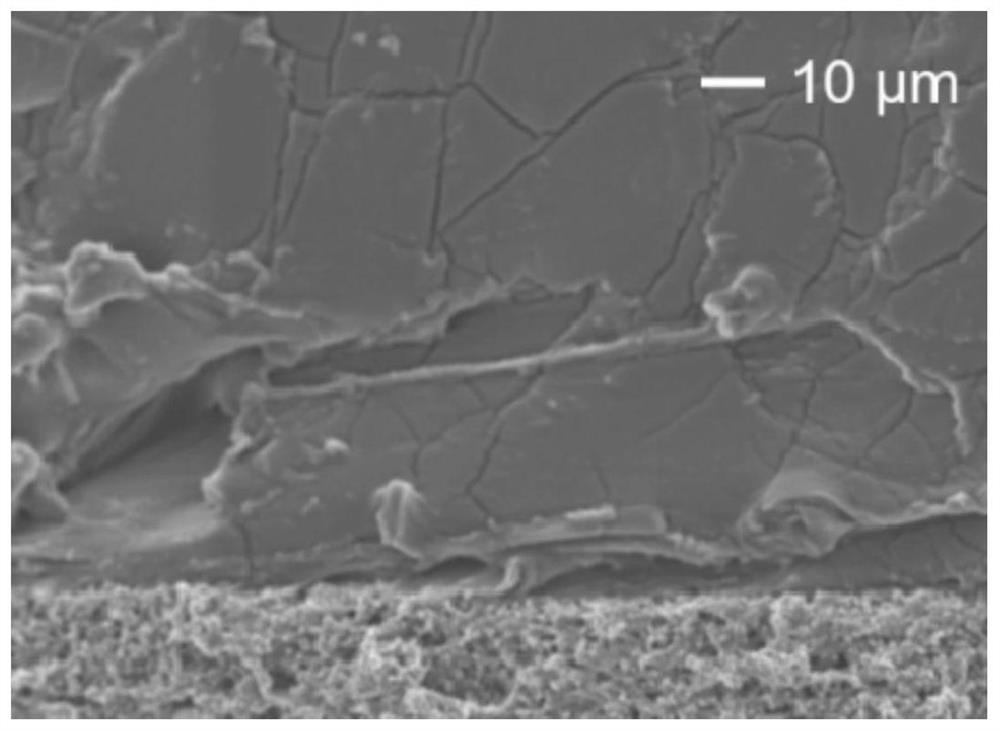

Image

Examples

Embodiment 1

[0032] (1) Polyethylene glycol diglycidyl ether (PEGDGE), polyetheramine (D2000) and lithium bistrifluoromethanesulfonimide (LiTFSI) were pre-dried in a vacuum oven.

[0033] (2) Add PEGDGE and LiTFSI (mass ratio: 1:0.22) into a screw bottle in a glove box, and stir at a constant temperature of 50°C for 12 hours (200r / min) until the lithium salt is completely dissolved. Similarly, add D2000 and LiTFSI (mass ratio: 1:0.25) into the screw bottle, and stir for 12 hours at a constant temperature of 50°C (rotating at 200r / min) until the lithium salt is completely dissolved.

[0034] (3) Add PEGDGE and D2000 (mass ratio: 2:3) dissolved in LiTFSI in step (2) into a screw bottle, and stir at a constant temperature of 50°C for 0.5h (rotating speed: 200r / min) until the system is evenly mixed.

[0035] (4) Put the mixed solution of step (3) into the transition chamber of the glove box to evacuate, and perform ultrasonic treatment for 0.5 h to remove air bubbles in the mixed solution.

...

Embodiment 2

[0040] (1) Polyethylene glycol diglycidyl ether (PEGDGE), polyether amine (D900) and lithium bistrifluoromethanesulfonimide (LiTFSI) were pre-dried in a vacuum oven.

[0041] (2) Put PEGDGE and D900 (1:1.4) into a screw bottle and add an appropriate amount of lithium bistrifluoromethanesulfonimide (LiTFSI) (the mass ratio of PEGDGE+D900 to LiTFSI is 1:0.1), at 50 Stir at constant temperature for 12 h (rotating at 200 r / min) until the lithium salt is completely dissolved.

[0042] (3) Quickly transfer to vacuum equipment, and pump out the gas in the mixed liquid in the screw bottle as much as possible.

[0043] (4) Pour the mixed liquid after vacuum treatment into the lower part of the mold mentioned above quickly, and put it into a vacuum oven, quickly place the upper part of the mold, and continue to cure for 3 hours under the vacuum condition of 100°C.

[0044] The mold was taken out from the vacuum oven, and the glass plate and release paper were removed to obtain an all-s...

Embodiment 3

[0049] (1) Polyethylene glycol diglycidyl ether (PEGDGE), polyether amine (D900) and lithium bistrifluoromethanesulfonimide (LiTFSI) were pre-dried in a vacuum oven.

[0050] (2) Put PEGDGE500 and D900 (1:1.4) into a screw bottle and add an appropriate amount of lithium bistrifluoromethanesulfonimide (LiTFSI) (the mass ratio of PEGDGE+D900 to LiTFSI is 1:0.4), at 50 Stir at constant temperature for 12 h (rotating at 200 r / min) until the lithium salt is completely dissolved.

[0051] (3) Quickly transfer to vacuum equipment, and pump out the gas in the mixed liquid in the screw bottle as much as possible.

[0052] (4) Pour the mixed liquid after vacuum treatment into the lower part of the mold mentioned above quickly, and put it into a vacuum oven, quickly place the upper part of the mold, and continue to cure for 3 hours under the vacuum condition of 100°C.

[0053] The mold was taken out from the vacuum oven, and the glass plate and release paper were removed to obtain an al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com