Novel fuel cell film electrode and preparation method thereof

A fuel cell membrane and electrode technology, applied to fuel cells, battery electrodes, circuits, etc., to achieve the effects of convenient quality monitoring, increased current density, and less fixed investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The first slurry (Recipe-1 slurry) is a platinum-containing catalyst slurry:

[0061] (1) 15.3g 50wt% Umicore platinum carbon catalyst (Vulcan XC carbon black);

[0062] (2) 21.2g D2020 Nafion solution;

[0063] (3) 31.8g deionized water

[0064] (4) 39.0g isopropanol

[0065] (5) 0.5g glycerin

[0066] (6) 0.05g water-soluble white dye, model BP-8095.

[0067] The second slurry (Recipe-2 slurry) is a non-platinum catalyst slurry:

[0068] (1) 15.3g carbon black, model: Vulcan XC;

[0069] (2) 21.2g Nafion solution, model D2020;

[0070] (3) 31.8g deionized water

[0071] (4) 39.0g isopropanol

[0072] (5) 0.5g glycerin

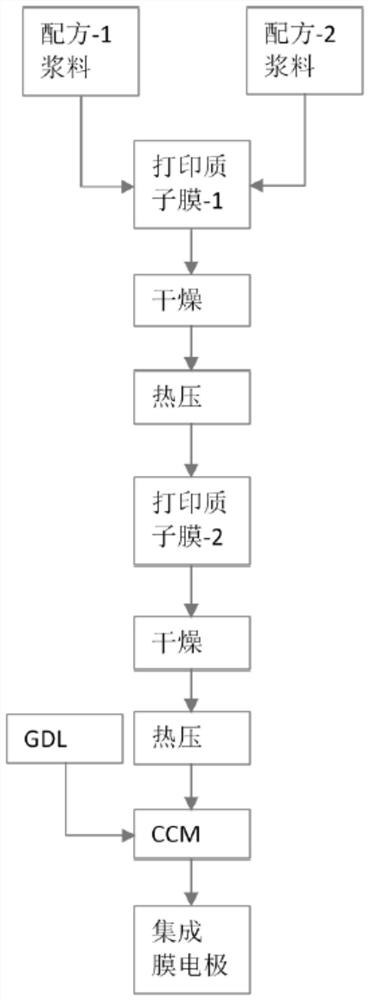

[0073] The first membrane electrode preparation process proposed by the present invention is as follows:

[0074](1) Slowly inject the above two slurries into the two ink cartridges of the inkjet printer with a syringe;

[0075] (2) Import the 2-D drawing of the plate design including ridges and flow channels into the computer software conne...

Embodiment 2

[0081] The first slurry (Recipe-1 slurry) is a platinum-containing catalyst slurry:

[0082] (1) 15.3g platinum carbon catalyst;

[0083] (2) 21.2g D2020 Nafion solution;

[0084] (3) 31.8g deionized water

[0085] (4) 39.0g isopropanol

[0086] (5) 0.5g glycerin

[0087] (6) 0.05g BP-8095 water-soluble white dye

[0088] The platinum-carbon catalyst includes platinum and carbon black, and the mass content of the platinum is 50%. Platinum is branded Umicore and carbon black is branded Vulcan XC.

[0089] The second slurry (Recipe-2 slurry) is a non-platinum catalyst slurry:

[0090] (1) 15.3g Vulcan XC carbon black;

[0091] (2) 21.2g D2020 Nafion solution;

[0092] (3) 31.8g deionized water

[0093] (4) 39.0g isopropanol

[0094] (5) 0.5g glycerin

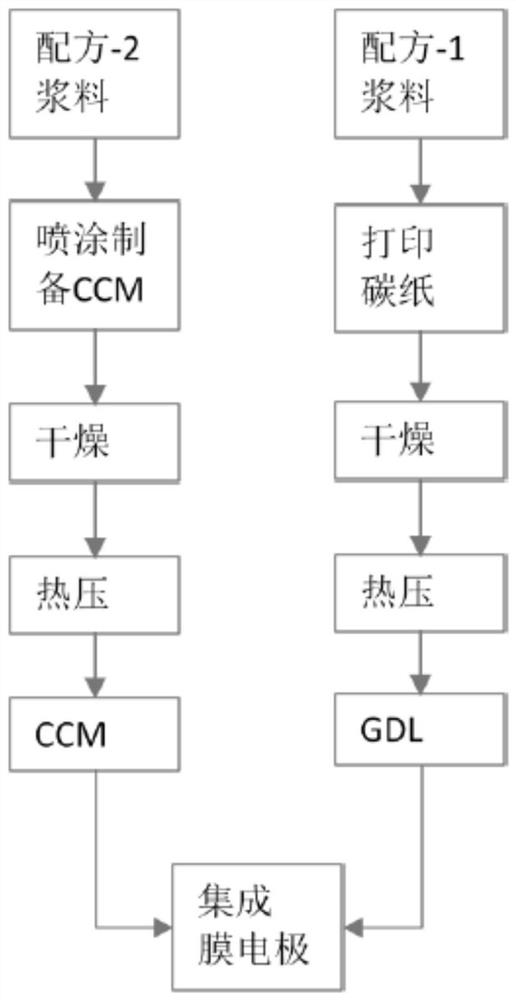

[0095] (1) Apply formulation-2 slurry evenly to the cathode and anode sides of the proton exchange membrane by spraying, coating or printing, then dry and heat press to form CCM.

[0096] (2) Then the formulation-1 slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com