Coating method of positive electrode material for lithium ion battery

A technology for lithium ion batteries and positive electrode materials, which is applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of affecting electrochemical reaction activity and poor conductivity, and achieves inhibition of redox side reactions and good conductivity. , the effect of high conductivity and lithium ion diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

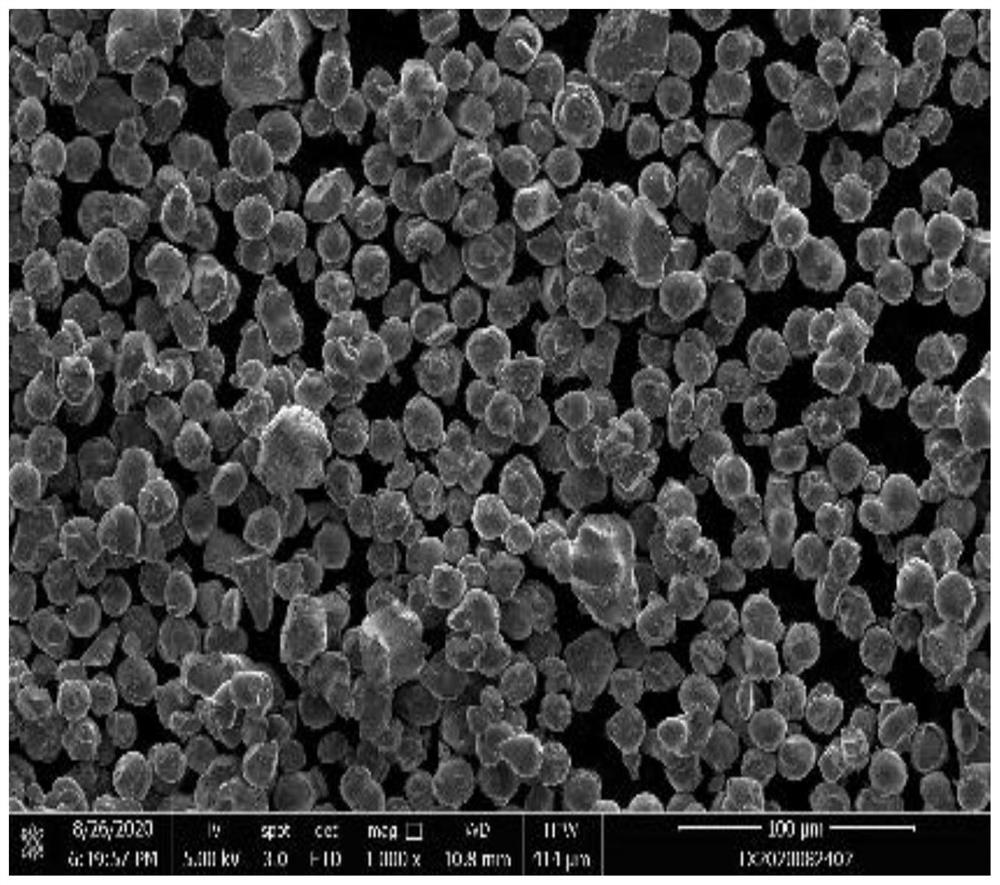

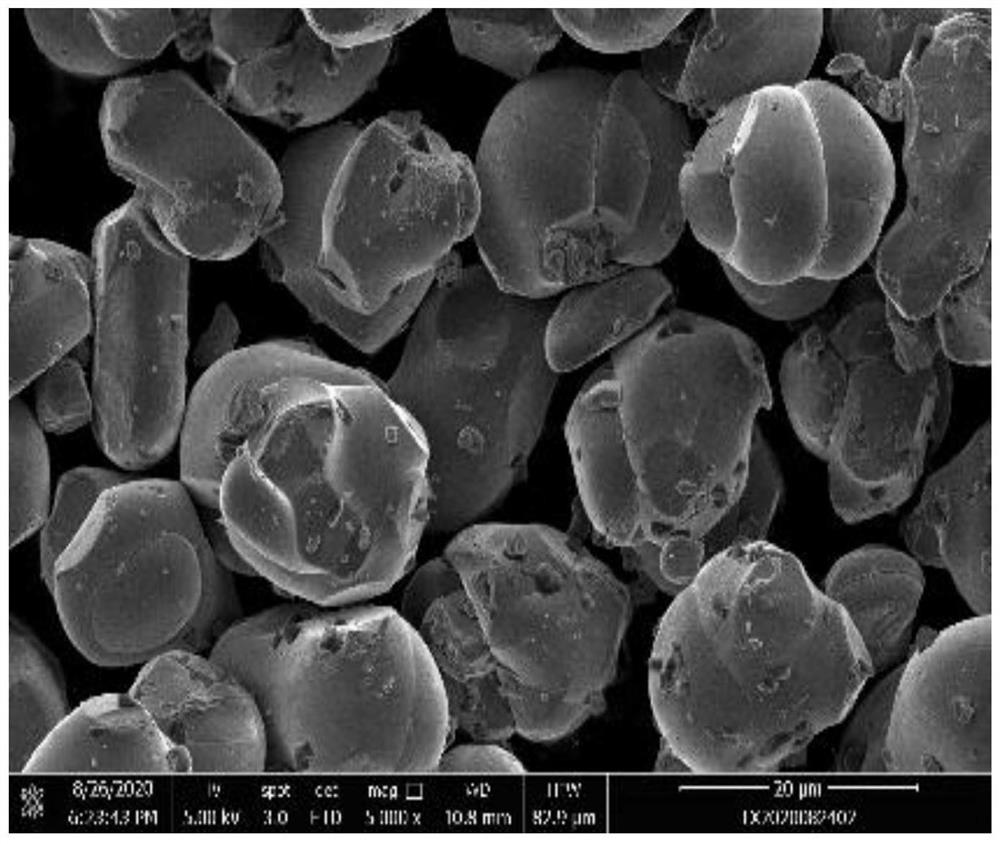

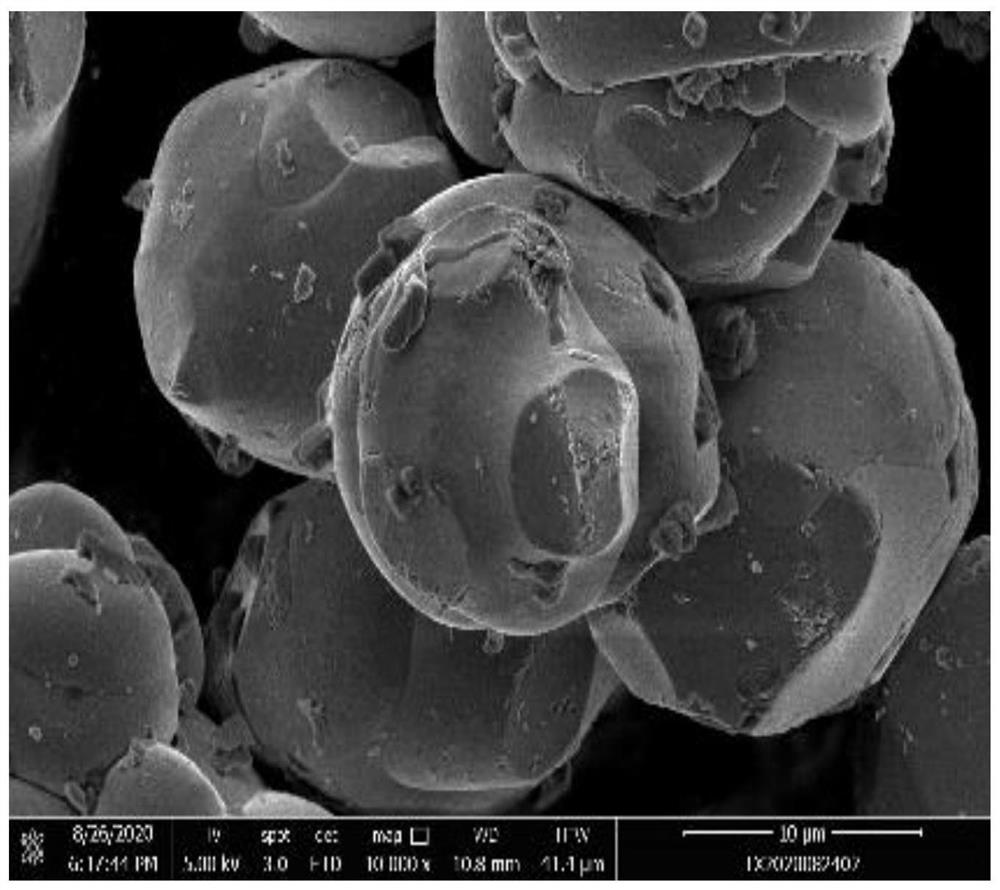

[0028] Weigh 200g of lithium cobalt oxide (LiCoO 2 ) positive electrode material powder, weigh 0.04g nano zirconium diboride (ZrB 2) powder, the lithium cobaltate positive electrode material powder and nano zirconium diboride powder to be coated are added to the planetary ball mill, and 200-300 grams of mixing balls are added, and after mixing for 30 minutes, the mixing balls are separated by passing through a 200-mesh sieve , to obtain mixed powder.

[0029] Transfer the mixed powder to a sagger, transfer the sagger to a muffle furnace, and heat up from room temperature to 900°C at a rate of 5°C / min for calcination for 10 hours. During the sintering process, air is continuously introduced as an oxygen source; After cooling to room temperature, it was taken out to obtain a sintered mixed powder.

[0030] Place the sintered mixed powder in a small universal pulverizer for 20 seconds, pour the pulverized sample into a 325-mesh sieve for sieving, collect the sieved sample, and ...

Embodiment 2

[0038] Weigh 200g of lithium cobalt oxide (LiCoO 2 ) positive electrode material powder, weigh 2g nano zirconium diboride (ZrB 2 ) powder, the lithium cobaltate positive electrode material powder and nano zirconium diboride powder to be coated are added to the planetary ball mill, and 200-300 grams of mixing balls are added, and after mixing for 30 minutes, the mixing balls are separated by passing through a 200-mesh sieve , to obtain mixed powder.

[0039] Transfer the mixed powder to a sagger, transfer the sagger to a muffle furnace, and heat up from room temperature to 900°C at a rate of 5°C / min for calcination for 10 hours. During the sintering process, air is continuously introduced as an oxygen source; After cooling to room temperature, it was taken out to obtain a sintered mixed powder.

[0040] Place the sintered mixed powder in a small universal pulverizer for 20 seconds, pour the pulverized sample into a 325-mesh sieve for sieving, collect the sieved sample, and ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com