Flue gas separation device

A separation device and flue gas technology, applied in lighting and heating equipment, fluidized bed combustion equipment, combustion methods, etc., can solve problems such as unstable combustion of boilers, easy blockage of flue gas separators, and increased number of furnace shutdowns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

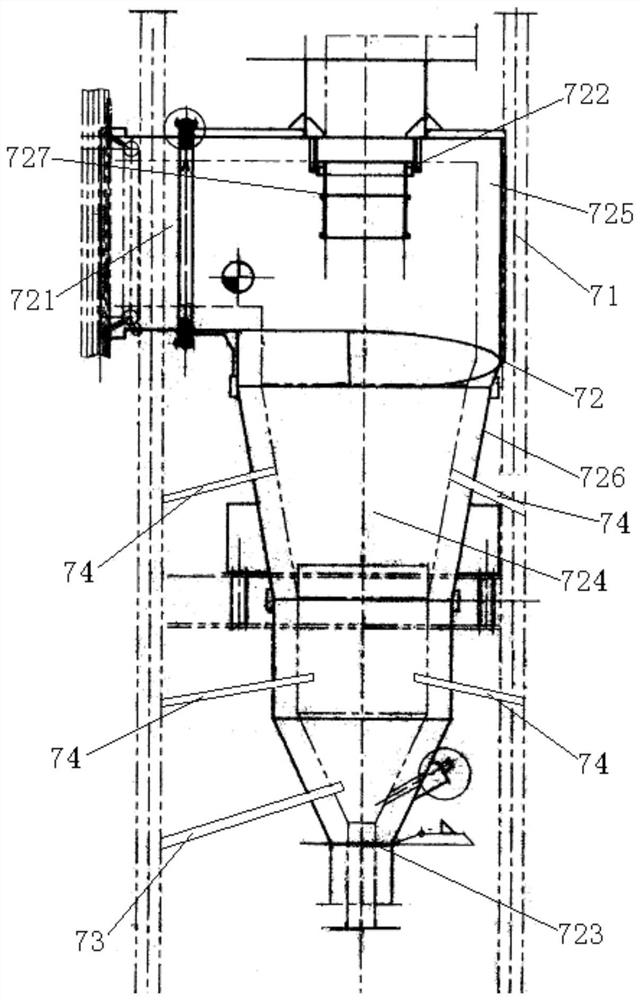

[0024] refer to figure 1 , a preferred embodiment of the present invention provides a flue gas separation device, comprising: a mounting frame 71 supported on the ground, and a flue gas separator 72 for separating the flue gas is supported on the mounting frame 71, the flue gas separation The device 72 is provided with a flue gas inlet 721 for the flue gas to be separated to enter, a flue gas outlet 722 for the separated fine particle flue gas to enter downstream processing, and a flue gas outlet 722 for the separated coarse particle flue gas to return to the circulating fluidized bed The flue gas outlet 723. Mounting frame 71 is also supported with shock wave air cannon 73, and the firing end of shock wave air cannon 73 is communicated with the flue gas passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com