Internally-wrapped combined heat-preservation pinch plate heat-insulation curtain wall

A gusset plate and curtain wall technology, applied in thermal insulation, walls, building components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

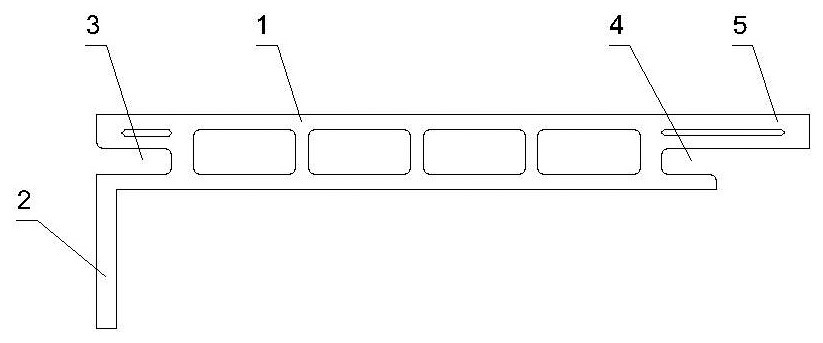

[0044] The end face structure diagram of an L-shaped insulation gusset plate is as follows figure 1 As shown, among them: 1 is the L-shaped insulation gusset, 2 is the rear connection plate of the L-shaped insulation gusset, 3 is the rear slot of the L-shaped insulation gusset, 4 is the front slot of the L-shaped insulation gusset, and 5 is the L-shaped insulation Gusset front outriggers.

Embodiment 2

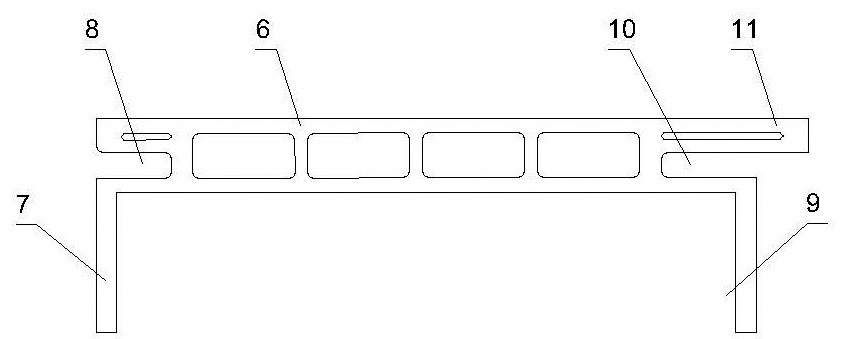

[0046] A structure diagram of the end face of a groove-type insulation gusset plate figure 2 As shown, among them: 6 is the slot-type insulation gusset, 7 is the rear connection plate of the groove-type insulation gusset, 8 is the rear slot of the groove-type insulation gusset, 9 is the front connection plate of the groove-type insulation gusset, and 10 is the slot-type insulation Slot before the gusset plate, 11 is the outstretched plate before the groove type insulation gusset plate.

Embodiment 3

[0048] The end face structure diagram of an L-shaped insulation gusset plate inlaid with glass is shown in the figure image 3 As shown, among them: 12 is the L-shaped insulation gusset plate inlaid with glass, 13 is the rear connecting plate of the L-shaped insulation gusset plate inlaid with glass, 14 is the rear slot of the L-shaped insulation gusset plate inlaid with glass, and 15 is the L-shaped insulation gusset plate inlaid with glass Type thermal insulation gusset front slot, 16 is the inlaid glass L-shaped thermal insulation gusset glass baffle, 17 is the glass baffle sealing strip groove, and 18 is the inlaid glass L-shaped thermal insulation gusset buckle inlaid groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com