Dredging equipment for water conservancy project

A technology for water conservancy projects and equipment, applied in the field of drainage equipment for water conservancy projects, can solve problems such as damage, the failure of the motor to start the load normally, and affect the service life of the motor, so as to prolong the service life, facilitate no-load start, and reduce damage. effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

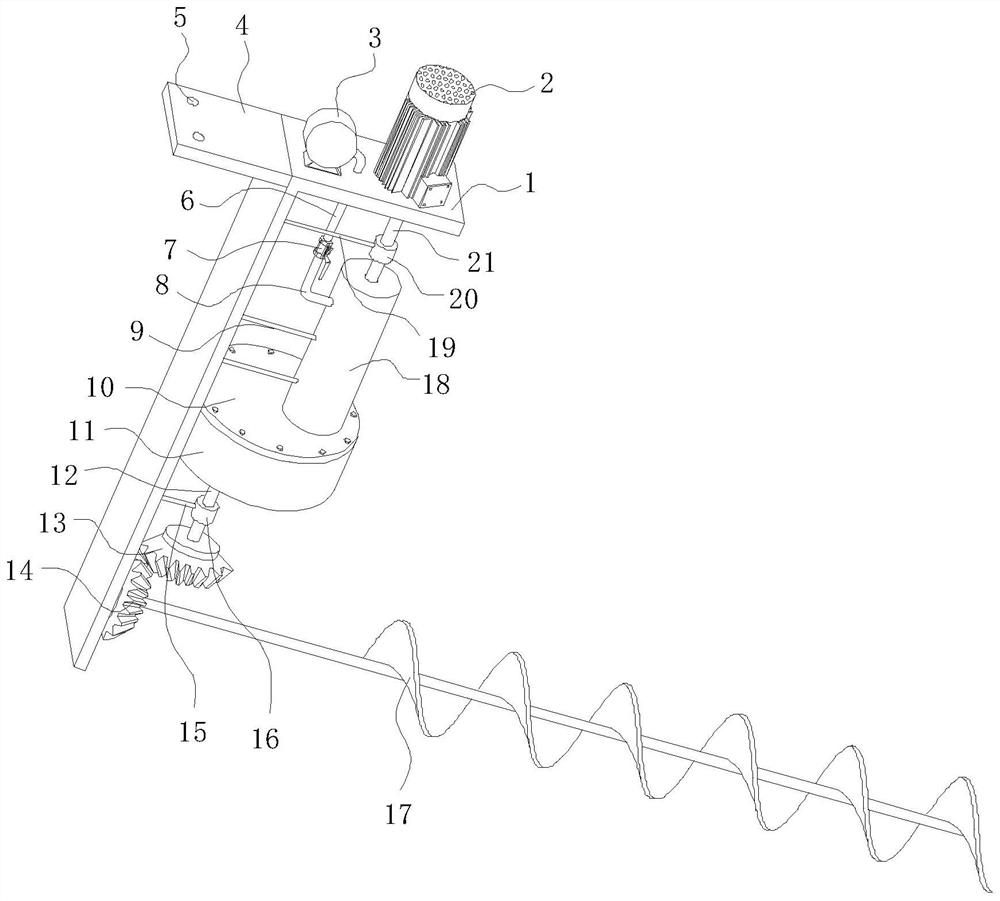

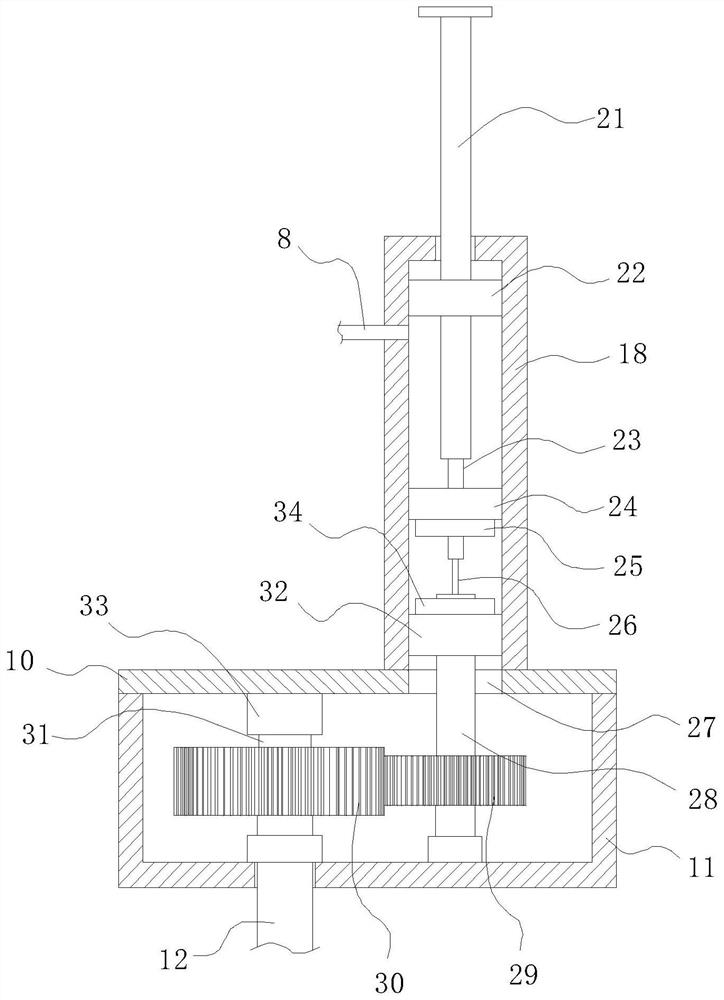

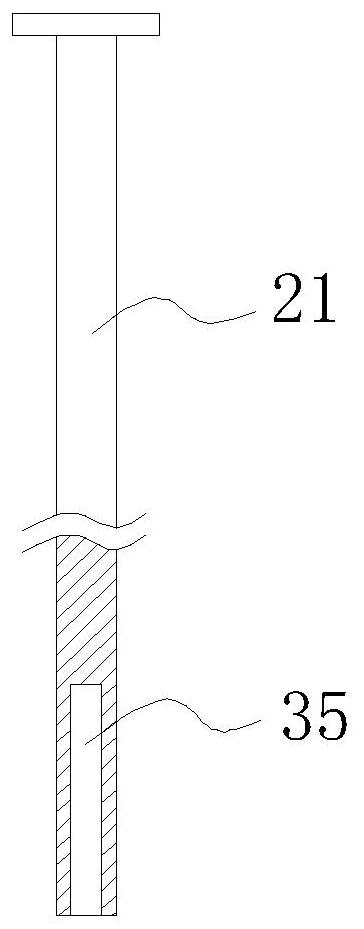

[0037] Specific embodiments: After starting the motor 2, open the shut-off valve 7, then control the air pump 3 to work, and then the air pump 3 works to transport the air into the cylinder 18 through the first air delivery pipe 6 and the second air delivery pipe 8, and the cylinder body After the air in 18 increases, the driving piston 24 slides downward in the cylinder 18, and then the square rod 23 in the first square hole 35 moves downward until the square rod 23 is inserted into the second square hole 36 on the connecting column 28 , to realize the insertion of the drive shaft 21 and the connecting column 28, the motor 2 drives the first gear 29 to rotate through the drive shaft 21 and the connecting column 28, and then the first gear 29 drives the transmission shaft 12 to rotate through the second gear 30, and the transmission shaft 12 passes through The first bevel gear 13 and the second bevel gear 14 drive the spiral blade 17 to rotate, realize the no-load start of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com