A fabric with infrared heating function and its preparation method

A cloth and functional technology, applied in the field of cloth with infrared heating function and its preparation, can solve the problems of limited heat preservation effect, achieve the effects of reducing infrared reflection, increasing anti-fouling ability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

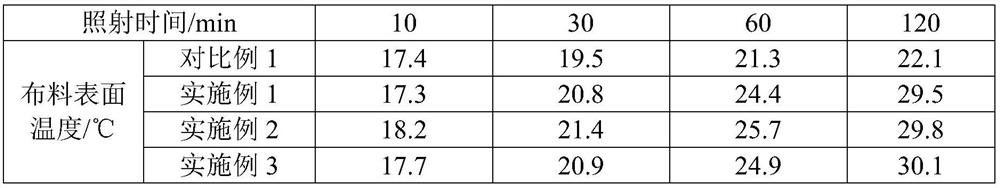

Examples

preparation example Construction

[0039] The preparation method of infrared absorbing solution is:

[0040] In parts by weight, in a light-proof environment, add 2-10 parts of organosilane to 50-90 parts of the mixed solution, adjust the pH to 4-5, and stir at 25-45 °C for 2-4 hours; Add 0.5-3 parts of silane coupling agent and 0.001-0.05 parts of catalyst and continue to stir for 12-24 hours; add 0.1-0.5 parts of infrared absorber and 1-10 parts of ultraviolet curing agent and stir evenly, and store in the dark for future use.

[0041] A method for preparing a cloth with infrared heating function, comprising the following steps:

[0042] The infrared absorbing solution is coated on the surface of the cloth or cloth fiber by spraying or dipping, and the desired cloth is obtained after irradiating with an ultraviolet lamp for 5-10 minutes in an environment of 60-80°C.

[0043] The mixed solution is a mixed solution in which the mixed solvent is deionized water and an organic solvent; the organic solvent is sel...

Embodiment 1

[0050] A method for preparing a cloth with infrared heating function, comprising the following steps:

[0051] (1) Preparation of mixed solution: water and ethanol are prepared by mixing water and ethanol at a volume ratio of 1:3;

[0052](2) Preparation of infrared absorbing solution: add 80g of mixed solution into the reaction kettle, add 10g of organosilane dodecyltrimethoxysilane, adjust pH=4-5, stir for 4h at a temperature of 25-45°C; add 3g Silane coupling agent vinyltrimethoxysilane, add catalyst dimethyl stannous 0.01g, continue to react for 24h; add 0.5g infrared absorber phthalocyanine blue BGS, 0.1g of 2-hydroxy-2-methyl-1-benzene methyl ketone and 9g urethane acrylate were stirred evenly, and kept away from light for later use;

[0053] (3) Dip-coat the infrared absorbing solution onto the surface of the fabric, and irradiate with an ultraviolet lamp for 5 minutes at 65°C to obtain a fabric with infrared heating function.

Embodiment 2

[0055] A method for preparing a cloth with infrared heating function, comprising the following steps:

[0056] (1) Preparation of mixed solution: water and ethanol are prepared by mixing water and ethanol at a volume ratio of 1:3;

[0057] (2) Preparation of infrared absorbing solution: add 50 g of the mixed solution into the reaction kettle, add 2 g of organosilane dodecyltrimethoxysilane, adjust pH=4-5, stir for 4 hours at a temperature of 25-45 °C; add 0.5 g silane coupling agent vinyltrimethoxysilane, add catalyst dimethyl stannous 0.001g, continue to react for 24h; add 0.1g infrared absorber nano-ITO, 0.1g of 2-hydroxy-2-methyl-1-phenyl Stir ketone and 1g polyurethane acrylate evenly, and store in the dark for future use;

[0058] (3) Dip-coat the infrared absorbing solution onto the surface of the fabric, and irradiate with an ultraviolet lamp for 5 minutes at 65°C to obtain a fabric with infrared heating function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com