Cow dung and earthworm microbial granular organic fertilizer production process

A technology of granular organic fertilizer and production process, which is applied in the treatment of biological organic parts, organic fertilizers, microorganisms, etc., can solve the problems of perishable decomposition of cow dung, natural fertilizer waste gas, and long fermentation time, so as to improve activity efficiency and improve Fermentation efficiency, rapid fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

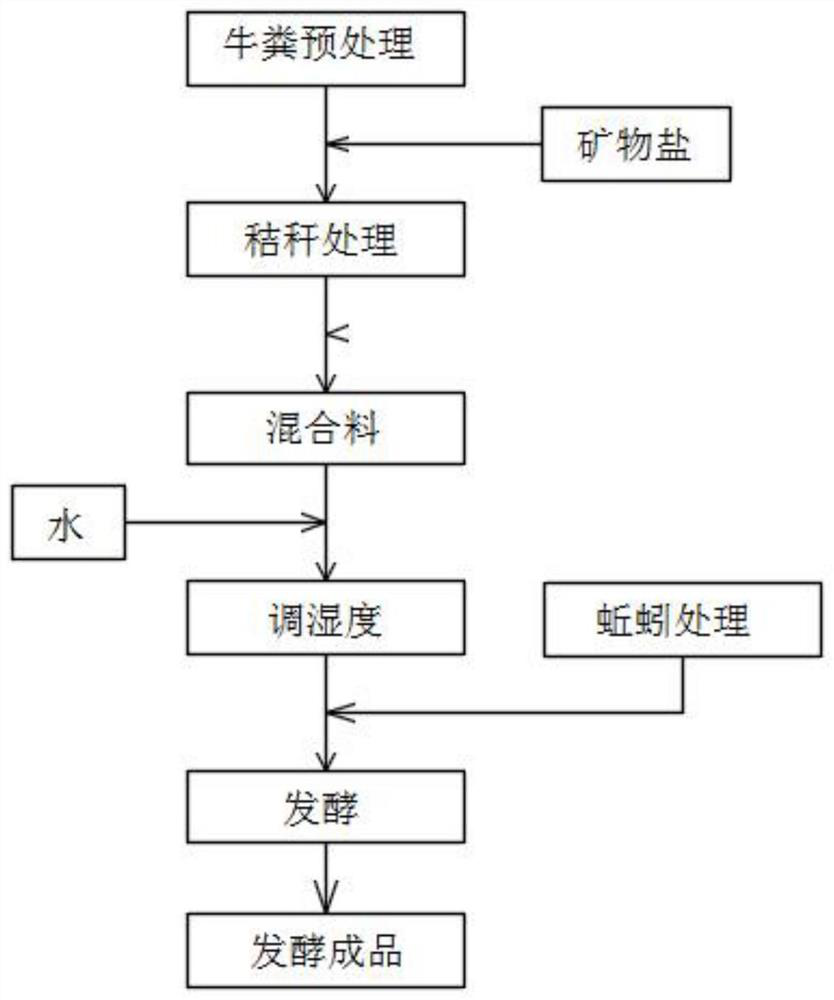

[0028] Include the following steps:

[0029] (1) Cow dung pretreatment: First, the cow dung is dried, pulverized and filtered to obtain cow dung powder particles. The purpose of drying is to facilitate the later setting and to facilitate the filtration of cow dung. It is inevitable that there will be some impurities. If they are left in the cow dung, they will affect the fermentation. Then they will be placed inside the static tank. The static tank is set up indoors. In order to avoid the influence of the environment, the cow dung needs to be added with mineral salt after drying and pulverizing. , the ratio of mineral salt to cow dung is 0.1:1, the purpose of adding mineral salt is to improve the activity of cow dung, and the microorganisms in cow dung can decompose it;

[0030] (2) Straw treatment: Take a certain amount of straw and grind it through a pulverizer. The particle diameter of the crushed straw is 0.2mm. After the straw and the mixed bacteria are mixed with cow dun...

Embodiment 2

[0036] (1) Cow dung pretreatment: First, the cow dung is dried, pulverized and filtered to obtain cow dung powder particles. The purpose of drying is to facilitate the later setting and to facilitate the filtration of cow dung. It is inevitable that there will be some impurities. If they are left in the cow dung, they will affect the fermentation. Then they will be placed inside the static tank. The static tank is set up indoors. In order to avoid the influence of the environment, the cow dung needs to be added with mineral salt after drying and pulverizing. , the ratio of mineral salt to cow dung is 0.1:1, the purpose of adding mineral salt is to improve the activity of cow dung, and the microorganisms in cow dung can decompose it;

[0037] (2) Straw treatment: Take a certain amount of straw and grind it through a pulverizer. The particle diameter of the crushed straw is 3mm. After the straw and mixed strains are mixed with cow dung, it needs to be stirred evenly twice, and ea...

Embodiment 3

[0043](1) Cow dung pretreatment: First, the cow dung is dried, pulverized and filtered to obtain cow dung powder particles. The purpose of drying is to facilitate the later setting and to facilitate the filtration of cow dung. It is inevitable that there will be some impurities. If they are left in the cow dung, they will affect the fermentation. Then they will be placed inside the static tank. The static tank is set up indoors. In order to avoid the influence of the environment, the cow dung needs to be added with mineral salt after drying and pulverizing. , the ratio of mineral salt to cow dung is 0.1:1, the purpose of adding mineral salt is to improve the activity of cow dung, and the microorganisms in cow dung can decompose it;

[0044] (2) Straw treatment: Take a certain amount of straw and grind it through a pulverizer. The particle diameter of the straw after crushing is 0.25mm. After the straw and the mixed bacteria are mixed with cow dung, they need to be stirred evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com