Non-fired antique green brick based on construction waste tailings and its preparation method and application

A technology for construction waste and antique blue bricks, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as environmental pollution, achieve broad market prospects, promote harmless and efficient use, and excellent water resistance Sexual and anti-aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

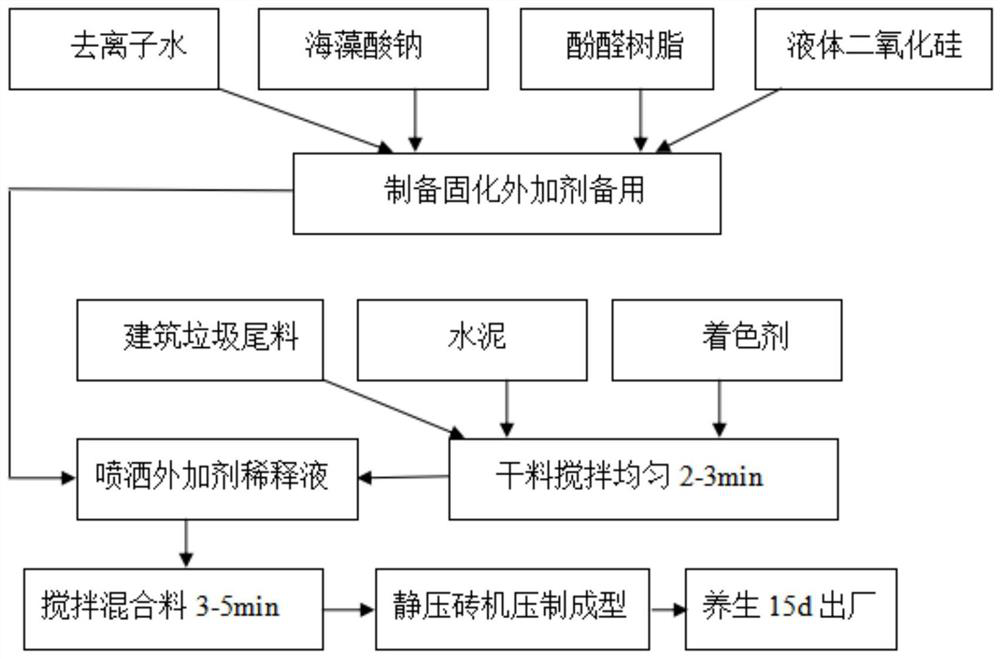

[0038] Another purpose of the embodiments of the present invention is to provide a method for preparing non-fired antique green bricks based on construction waste tailings (that is, a method for making unfired antique green bricks using construction waste tailings). The preparation method of the non-fired antique blue brick based on construction waste tailings comprises the following steps:

[0039] Weigh the inorganic solvent (preferably deionized water), sodium alginate, phenolic resin, liquid silicon dioxide, etc. according to the proportion, heat, stir and mix them uniformly in the reaction kettle to prepare the curing agent;

[0040] Weigh water according to the proportion and add it to the curing agent to mix evenly to obtain a diluent;

[0041] Weigh the tailings of construction waste, cement and colorant according to the proportion and mix them evenly, and then mix them evenly with the diluent (by spraying) to obtain the mixture;

[0042] The mixed material is hydraul...

Embodiment 1

[0058] A kind of non-fired archaized blue brick based on construction waste tailings, the specific preparation method is as follows (refer to figure 1 shown):

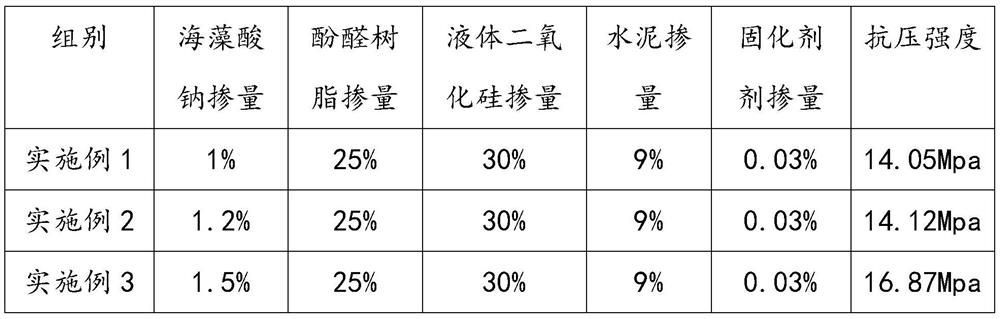

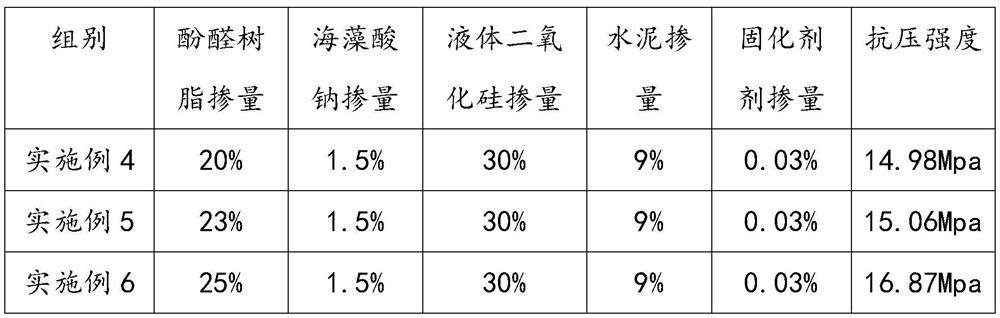

[0059] 1) Preparation of curing agent (curing admixture): Inject 440kg of deionized water into a reaction kettle with a heating system, heat it to 70°C, add 10kg of sodium alginate, stir for 20min, and heat at the same time to make the temperature in the reaction kettle Raise to 80°C, keep warm for 1h; cool down to 40°C; add 250kg of sulfonated phenolic resin and stir for 1h until it is completely dissolved, then naturally cool to 20°C; add 300kg of liquid silica for full stirring; measure the density at 1.26g / mL, filter, obtain the curing agent of the present embodiment formula, for subsequent use;

[0060] 2) Stirring the mixture: Weigh 900kg of construction waste tailings, 90kg of cement, and 10kg of coloring agent and carry out uniform mixing for 2-3min to obtain a dry mixture; simultaneously take 0.3kg of the ab...

Embodiment 2

[0064] A kind of non-fired archaized blue brick based on construction waste tailings, the specific preparation method is as follows (refer to figure 1 shown):

[0065] 1) Preparation of curing agent (curing admixture): Inject 438kg of deionized water into a reaction kettle with a heating system, heat it to 70°C, add 12kg of sodium alginate, stir for 20min, and heat at the same time to make the temperature in the reaction kettle Raise to 80°C, keep warm for 1h; cool down to 40°C; add 250kg of sulfonated phenolic resin and stir for 1h until completely dissolved, then naturally cool to 20°C; add 300kg of liquid silica and stir thoroughly; measure the density at 1.27g / mL left and right, filter, obtain the solidifying agent of this embodiment formula, for subsequent use;

[0066] 2) Stirring the mixture: Weigh 900kg of construction waste tailings, 90kg of cement, and 10kg of coloring agent and carry out uniform mixing for 2-3min to obtain a dry mixture; simultaneously take 0.3kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com