Method for preparing rare earth doped NaBiF4 nanoparticles by ultrasonic solution method and application thereof

A rare earth doping, nanoparticle technology, applied in chemical instruments and methods, inorganic chemistry, luminescent materials, etc., to achieve the effect of shortening the time of synthesis process, solving cost, and rapid synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Dissolve bismuth nitrate and sodium nitrate in ethanol at a molar ratio of 1:2 to form a transparent solution; prepare an ethanol solution of ammonium fluoride, and the amount of ammonium fluoride is 6 times that of bismuth nitrate. At a room temperature of 4 degrees Celsius, the ethanol solution of ammonium fluoride was quickly mixed with the solutions of bismuth nitrate and sodium nitrate. Under the ultrasonic power of 200W, the color of the mixed solution instantly changed to milky white; after a reaction time of 60s, milky white was obtained. mixed solution. Use a centrifuge for solid-liquid separation at a centrifugation rate of 8000 rpm to obtain a white powder; dry the white powder at a temperature of 60 degrees Celsius to obtain pure NaBiF 4 Nano powder.

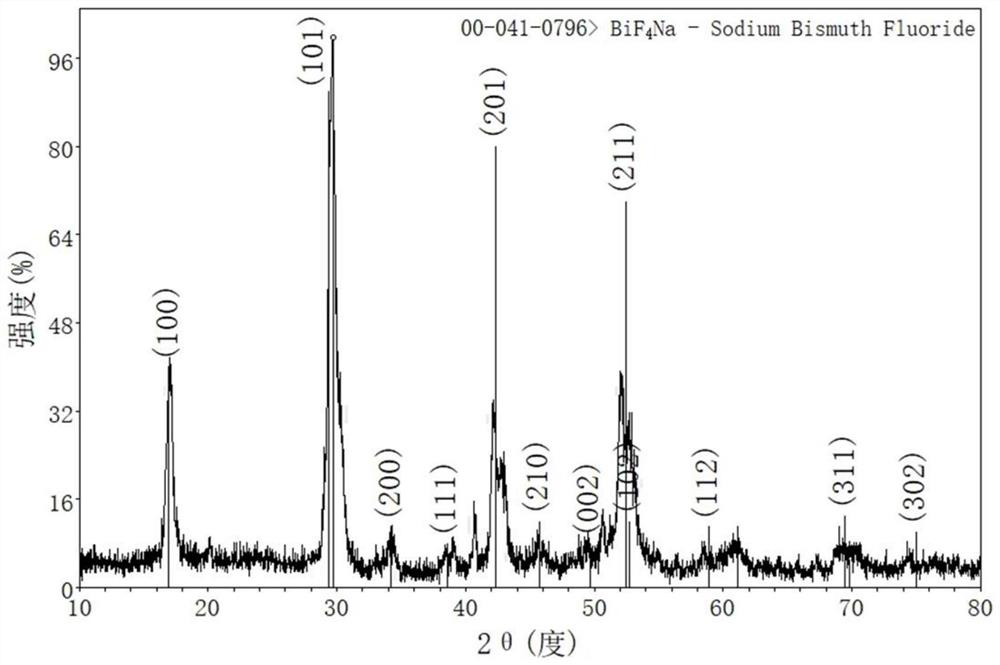

[0072] Such as figure 1 As shown, the obtained powder was scanned between 10 and 80 degrees by X-ray diffractometer, and all the diffraction peaks and NaBiF 4 The standard card (PDF: 00-041-0796) is complet...

Embodiment 2

[0074] Dissolve bismuth acetate and sodium nitrate in ethanol at a molar ratio of 1:4 to form a transparent solution; prepare an ethanol solution of ammonium fluoride, and the amount of ammonium fluoride is 16 times that of bismuth nitrate. At a room temperature of 30 degrees Celsius, the ethanol solution of ammonium fluoride was quickly mixed with the solutions of bismuth nitrate and sodium nitrate. Under the ultrasonic power of 400W, the color of the mixed solution instantly changed to milky white; after a reaction time of 30s, milky white was obtained. mixed solution. Solid-liquid separation is carried out by static precipitation, and the white powder can be obtained by pouring off the ethanol solution in the upper layer; the white powder can be dried at a temperature of 70 degrees Celsius to obtain pure NaBiF 4 Nano powder.

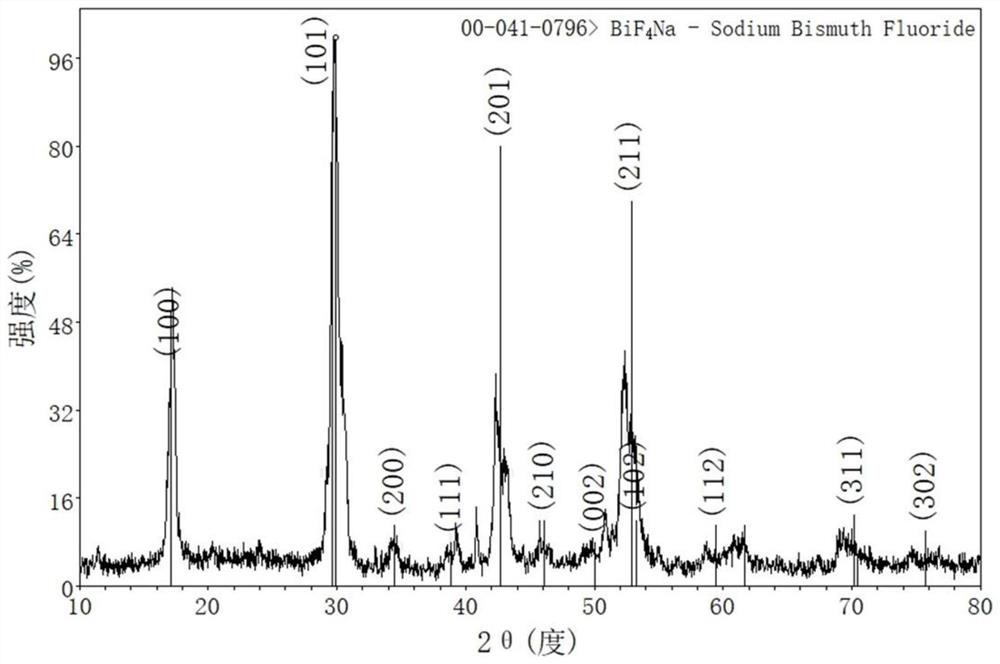

[0075] figure 2 Given the obtained powder using X-ray diffraction pattern, all diffraction peaks and NaBiF 4 The standard card (PDF: 00-041-0796)...

Embodiment 3

[0077] Dissolve bismuth nitrate and sodium nitrate in isopropanol at a molar ratio of 1:6 to form a transparent solution; add rare earth nitrate solution, wherein the amount of samarium nitrate is 0.1% of bismuth nitrate; prepare ammonium fluoride In isopropanol solution, the amount of ammonium fluoride is 20 times that of bismuth nitrate. At a room temperature of 40 degrees Celsius, the isopropanol solution of ammonium fluoride was quickly mixed with the solutions of bismuth nitrate and sodium nitrate. Under the ultrasonic power of 100W, the color of the mixed solution instantly changed to milky white; after a reaction time of 300s, obtained A milky white mixed solution was formed. Use a centrifuge for solid-liquid separation at a centrifugation rate of 12,000 rpm to obtain a white powder; dry the white powder at a temperature of 50 degrees Celsius to obtain Sm-doped NaBiF 4 Nano powder.

[0078] image 3 Given the obtained powder using X-ray diffraction pattern, all diffr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com