NH4Yb2F7-based nanoparticles and preparation method and application thereof

A technology of nanoparticles and clarified solution, applied in the fields of nanotechnology, nano-optics, nanotechnology, etc., can solve problems such as lack of realization, shorten the time of synthesis process, solve hidden dangers of biological safety and environmental pollution, and speed up the synthesis process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

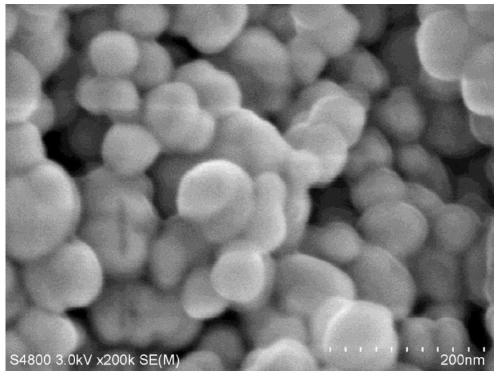

[0045] Dissolve 1 mmol of ytterbium nitrate in 20 mL of distilled water, and form a transparent solution by magnetic stirring; then dissolve 8 mmol of ammonium fluoride in the transparent solution; at room temperature of 25 degrees, after one minute of reaction time, a milky white mixture is obtained. solution. Use a centrifuge for solid-liquid separation at a centrifugal rate of 5000 rpm to obtain a white powder; dry the white powder at 50°C to obtain NH 4 Yb 2 f 7 Nano powder.

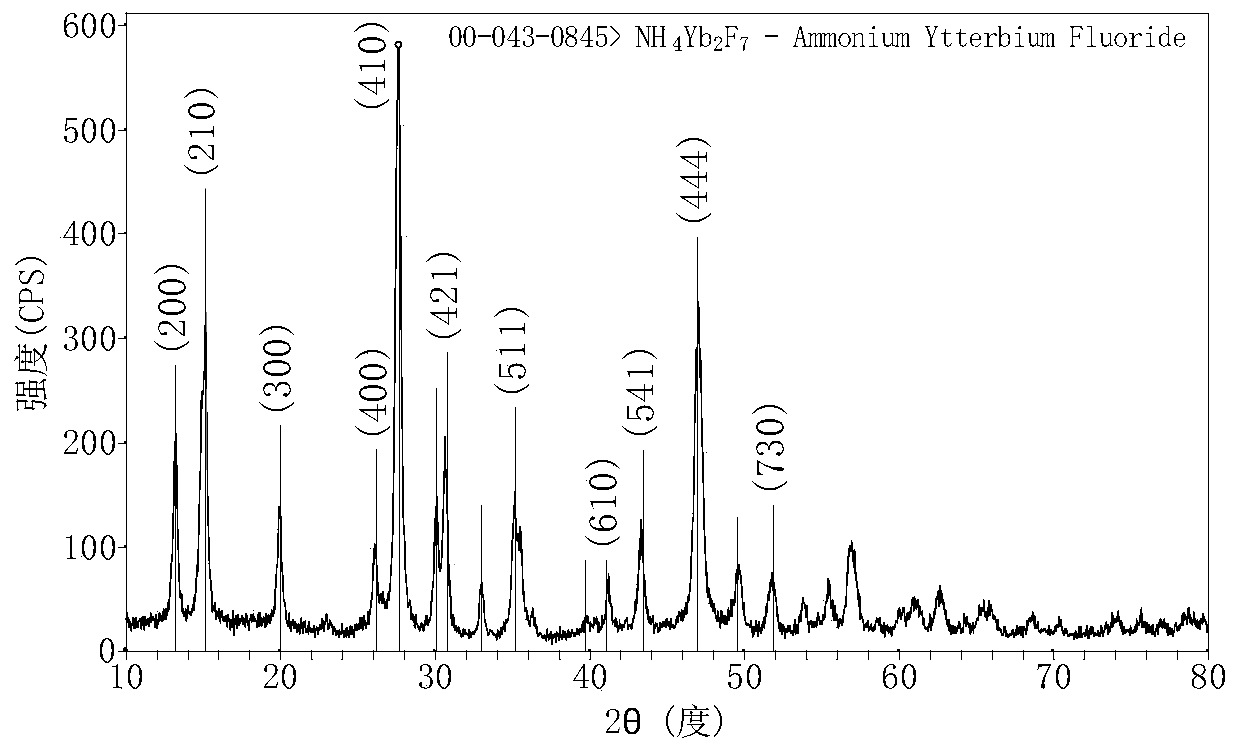

[0046] Such as figure 1 As shown, the obtained NH 4 Yb 2 f 7 The powder is scanned by X-ray diffractometer between 10 and 50 degrees, all diffraction peaks and NH 4 Yb 2 f 7 The standard card (PDF: 00-043-0845) is completely consistent, without any miscellaneous peaks, proving that the obtained powder is NH 4 Yb 2 f 7 pure phase. Among them, the standard card (PDF: 000-043-0845) is a pure hexagonal phase structure, and the lattice constant is processed as a=b after refinement and fitting...

Embodiment 2

[0049] Dissolve ytterbium nitrate and thulium nitrate in 20ml of deionized water at a molar ratio of 0.9:0.1, and form a transparent solution by magnetic stirring; then dissolve 9 mmol of ammonium fluoride in the transparent solution; react at room temperature 40 degrees for one minute After time, a milky white mixed solution was obtained. Use a centrifuge for solid-liquid separation at a centrifugal rate of 8000 rpm to obtain a white powder; dry the white powder at 70°C to obtain Tm-doped NH 4 Yb 2 f 7 Nano powder.

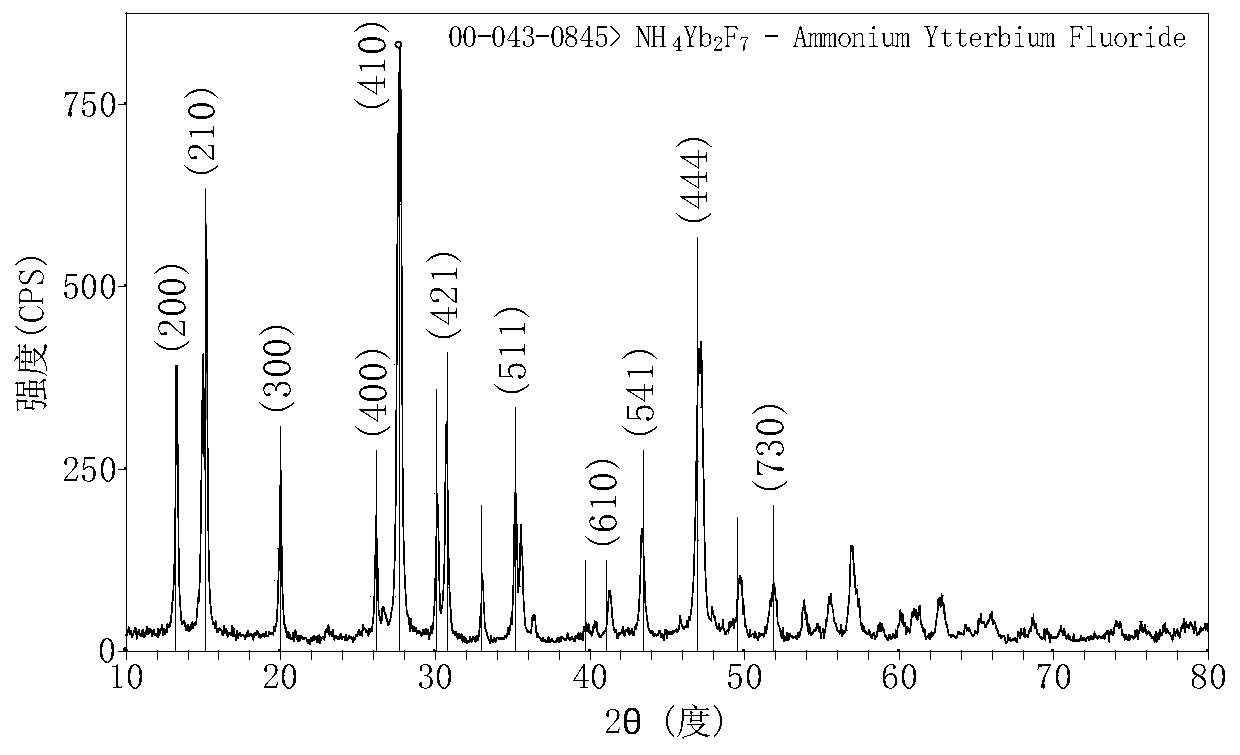

[0050] Such as image 3 As shown, the obtained NH 4 wxya 7 The powder is scanned by X-ray diffractometer between 10 and 50 degrees, all diffraction peaks and NH 4 Yb 2 f 7 The standard card (PDF: 00-043-0845) is completely consistent without any miscellaneous peaks, which proves that the obtained powder is NH 4 Yb 2 f 7 phase structure and doping with 10% Tm did not change the NH 4 wxya 7 Structure.

Embodiment 3

[0052] Dissolve ytterbium nitrate and thulium nitrate in 20ml of water at a molar ratio of 0.8:0.2, and form a transparent solution by magnetic stirring; then dissolve 20mmol of ammonium fluoride in the transparent solution; After a reaction time, a milky white mixed solution was obtained. Use a centrifuge for solid-liquid separation at a centrifugation rate of 9000 rpm to obtain a white powder; dry the white powder at 80°C to obtain Tm-doped NH 4 Yb 2 f 7 Nano powder.

[0053] Such as Figure 4 As shown, the obtained NH 4 Yb 2 f 7 The powder is scanned by X-ray diffractometer between 10 and 50 degrees, all diffraction peaks and NH 4 Yb 2 f 7 The standard card (PDF: 00-043-0845) is completely consistent, without any miscellaneous peaks, proving that the obtained powder is NH 4 Yb 2 f 7 phase and 20% Tm doping did not change the NH 4 Yb 2 f 7 Structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com