A system and method for continuous hydrogen extraction and reuse of tail gas

A tail gas and hydrogen technology, applied in chemical instruments and methods, hydrogen, hydrogen separation, etc., can solve problems such as inability to efficiently recover tail gas, and achieve the effect of low material price, high activity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

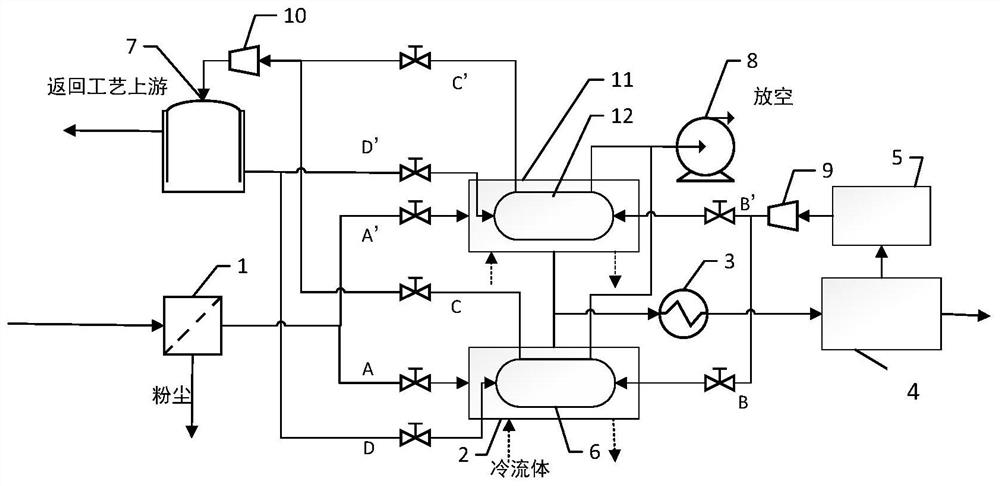

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] Aiming at the comprehensive utilization of tail gas in the production process of semiconductor light-emitting diode (LED) epitaxial wafers, the present invention proposes a system and method for continuous hydrogen extraction and reuse of tail gas, which is realized based on metal hydride and waste heat drive, and has reliable operation and energy efficiency. It has the advantages of low consumption and high purity of recovered hydrogen.

[0033] see figure 1 , the present invention provides a tail gas hydrogen extraction and reuse system, including a filter 1, a first heat exchanger 2, a cooling device 3, a first metal hydride hydrogen storage reactor 6, a water absorption unit 4, and a water removal unit 5 , the first booster pump 9, the vacuum pump 8, the first booster pump 10, the hydrogen storage tank 7, the second heat exchanger 11 and the second metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com