A blackboard surface sandblasting device with waste recycling function

A technology for surface sandblasting and waste recycling, which is applied to used abrasive treatment devices, abrasive jetting machine tools, abrasives, etc. It can solve problems such as inability to recycle sand, and achieve the effect of reducing waste and good fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

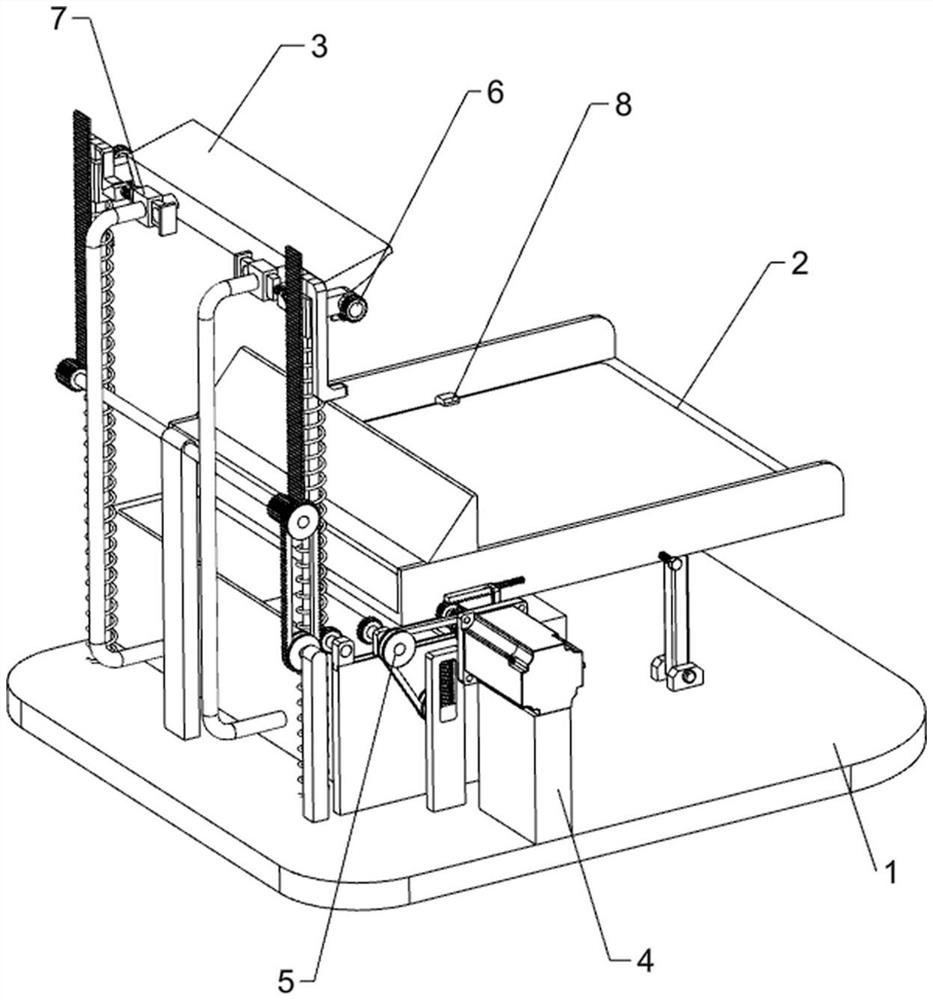

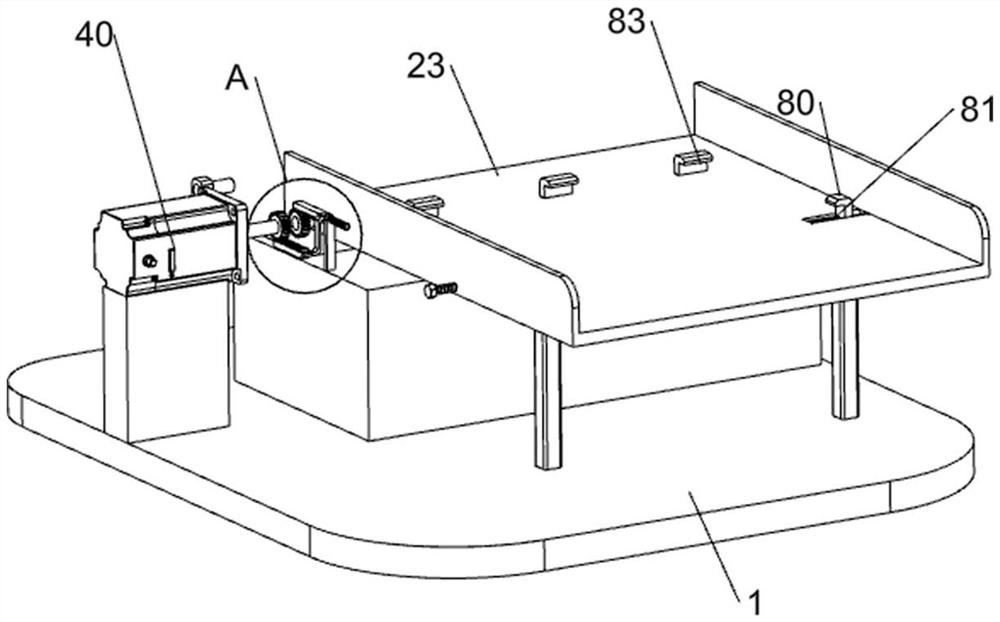

[0028] A blackboard surface sandblasting device with waste recycling function, such as figure 1 , figure 2 , image 3 and Figure 6 As shown, it includes a bottom plate 1 , a placing mechanism 2 and a sandblasting mechanism 3 , the bottom plate 1 is provided with a placement mechanism 2 , and the bottom plate 1 is provided with a sandblasting mechanism 3 .

[0029] When people need to use this device, first people place the blackboard in the placing mechanism 2, then people fix the blackboard, then add enough sand in the sandblasting mechanism 3, and then people just turn the placing mechanism 2 to the left The placement mechanism 2 drives the blackboard to rotate to the left, and when the placement mechanism 2 is turned to a suitable position, people can start the sandblasting mechanism 3, so that the sandblasting mechanism 3 can sandblast the blackboard. Mechanism 3 moves up and down, makes sandblasting mechanism 3 carry out sandblasting to blackboard evenly, treats that...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the transmission mechanism 4 is also included, and the transmission mechanism 4 includes a servo motor 40, a second rotating shaft 41, a first gear 42, a first rack 43, a second rack 44, a second gear 45, a mounting block 46, a Two connecting rods 47 and the second spring 48, the front side of the bottom plate 1 top is provided with a servo motor 40, the output shaft of the servo motor 40 is provided with a second rotating shaft 41, the second rotating shaft 41 is provided with a first gear 42, and a sand storage pot 35 A mounting block 46 is provided on the front side of the top, and a second connecting rod 47 is slidably arranged on the mounting block 46, and a first rack 43 is provided on the left side of the second connecting rod 47, and the first rack 43 meshes with the first gear 42. The left end of the second connecting rod 47 is provided with a second rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com